Incandescent light

A technology for permanent lights and gas pipelines, applied in the field of permanent lights, can solve problems such as easy damage to pipelines, easy fuel leakage, easy erosion of ejectors, etc., and achieve the effects of improving safety factor, improving flame rigidity, and reducing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

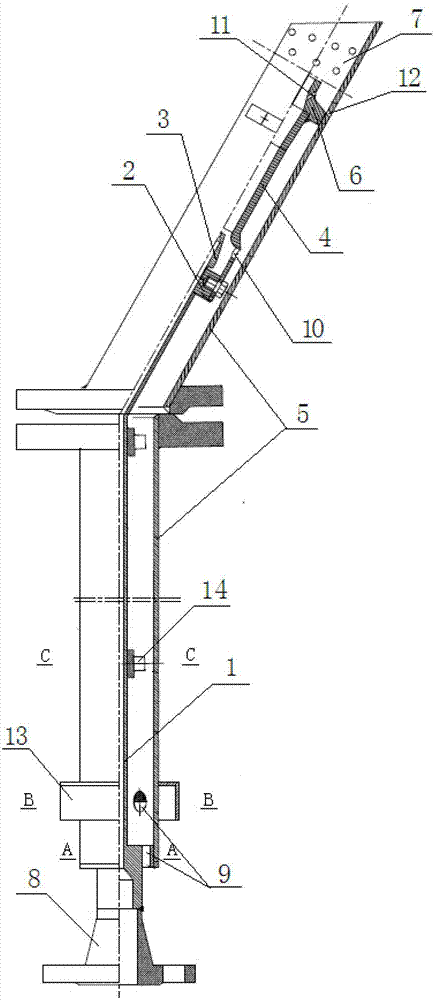

[0022] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

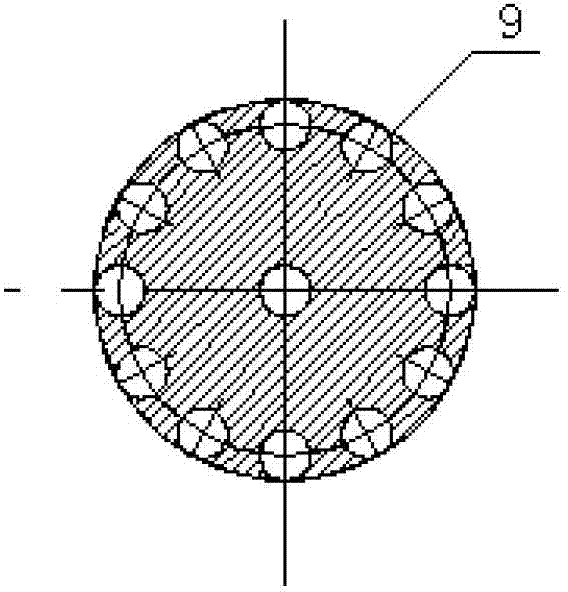

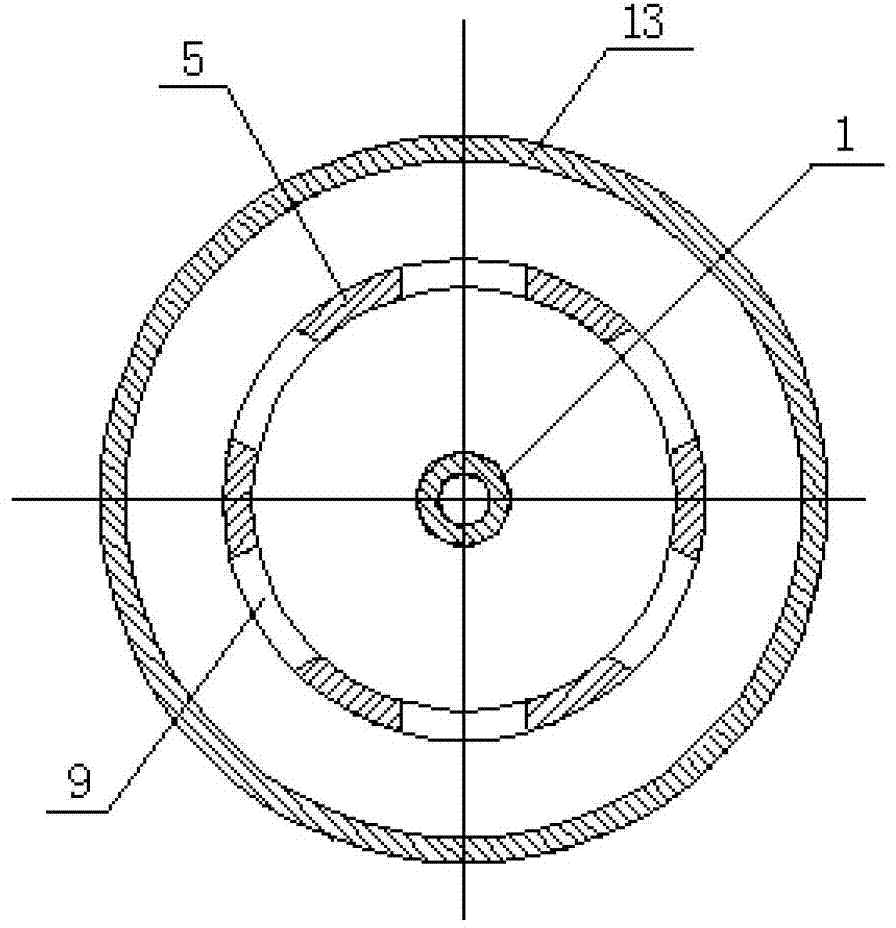

[0023] An ever-burning lamp, comprising a gas pipeline 1, a nozzle seat 2, a gas nozzle 3, an injector 4, a burner 6, an outer wall sleeve 5, a windshield 7 and a flange base 8, wherein the gas pipeline 1 is bent, and its The upper end is provided with a nozzle seat 2, and the gas nozzle 3 is threadedly connected with the nozzle seat 2, so different types of gas nozzles 3 can be replaced as required, and the front end of the injector 4 is connected with the outside of the nozzle seat 2 through bolts, and the lead The side of the injector 4 is provided with a plurality of injection holes 10, and its tail end is welded with a burner 6, and the side of the burner 6 is provided with a circle of flame stabilizing holes 11; the outer wall sleeve 5 includes two parts, respectively The upper casing and the lower casing are sleeved on the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com