Combustion unit allowing hot gas generated by pulverized coal combustion to be subjected heat exchange with water

A technology of pulverized coal combustion and water exchange, which is applied in the direction of burning powder fuel burners, combustion product treatment, burners, etc. It can solve the problems of high heat loss, large heat exchange surface consumables, and environmental protection of exhaust smoke components. Achieve the effects of improving flame rigidity, preventing coking and burning, and protecting the wall surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

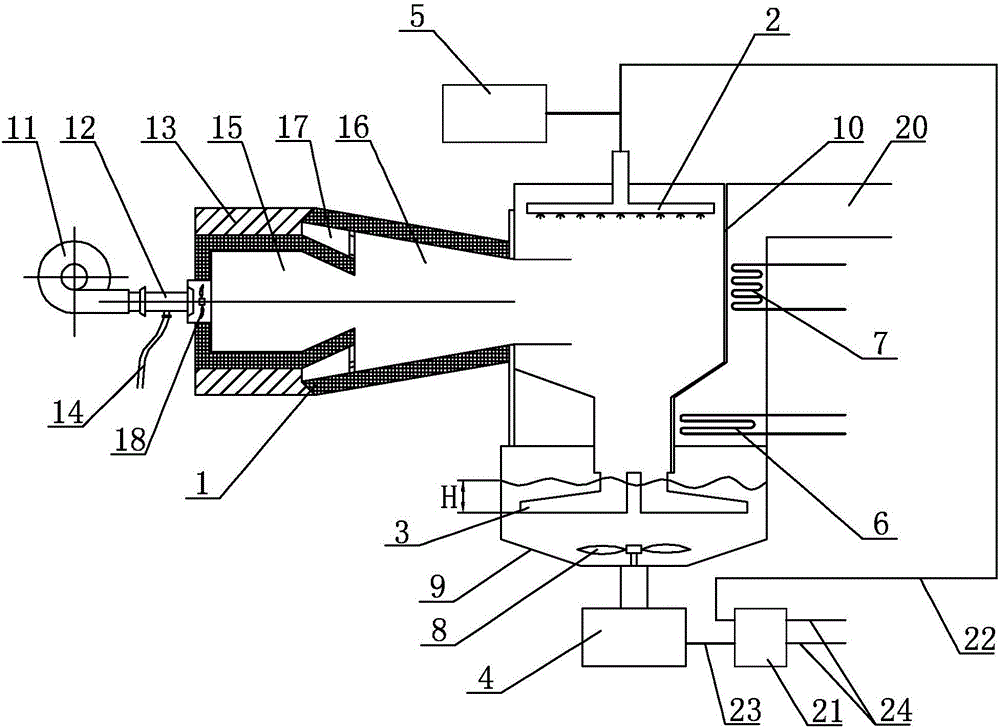

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, which includes a burner 1, a spray mechanism 2, a flue gas cooling pipe 3, a centrifugal slag remover 4, a flue gas condensation heat exchange coil 6, a heat pump heat exchange coil 7, and spoiler blades 8. The water tank 9, the spray tank body 10 and the flue 20, the spray tank body 10 and the centrifugal slag remover 4 are respectively arranged above and below the water tank 9, and the spray tank body 10 and the centrifugal slag remover 4 are all connected with each other. The water tank 9 is connected, the flue gas cooling pipe 3 is arranged in the water tank 9, and the flue gas cooling pipe 3 is installed at the lower end of the spray tank body 10, the spoiler blade 8 is arranged in the water tank 9, and the spoiler blade 8 is arranged in the centrifugal At the entrance of the slag remover 4, the flue 20 communicates with the water tank 9, the spray mechanism 2 is arranged on the top of the...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 This embodiment will be described. The secondary air blower 13 in this embodiment swirls the secondary air along the pre-combustion chamber 15 into the combustion chamber 16 . This design makes the secondary air be sent into the combustion chamber 16 after being preheated by the outer wall of the pre-combustion chamber 15, so as to increase the temperature of the secondary air. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Describe this embodiment, in this embodiment, the shape of the flue gas heat dissipation pipe 3 is conical, the diameter of the upper end of the flue gas heat dissipation pipe 3 is smaller than the diameter of the lower end, and the lower end surface of the flue gas heat dissipation pipe 3 is provided with a plurality of small holes, each The diameter of each small hole is 20mm to ensure that the flow velocity of the flue gas exits the hole at 10m / s~15m / s. The flue gas cooling pipe 3 disperses the flue gas into small bubbles to directly contact with water for heat exchange. The small holes are used for water outlet, and the number of small holes can be arranged according to the unit capacity and operation needs. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com