Integrated gun for start-up burner, start-up burner, using method and industrial furnace

A technology for starting burners and channels, which is applied in the field of integrated guns for starting burners and industrial furnaces. It can solve the problems of high risk of blowing out, false alarms of flame detectors, and low automation, and achieves a simple overall structure and a The effect of reduced diameter and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The technical parameters are as follows: The technical parameters are as follows:

[0074] Ventilation Form - Starting the Extension to Quite Nature Ventilation, Configure the I-Bunner Mount

[0075] Fuel species - liquefied petroleum gas

[0076] Design load - 500 × 10 4 KCAL / H

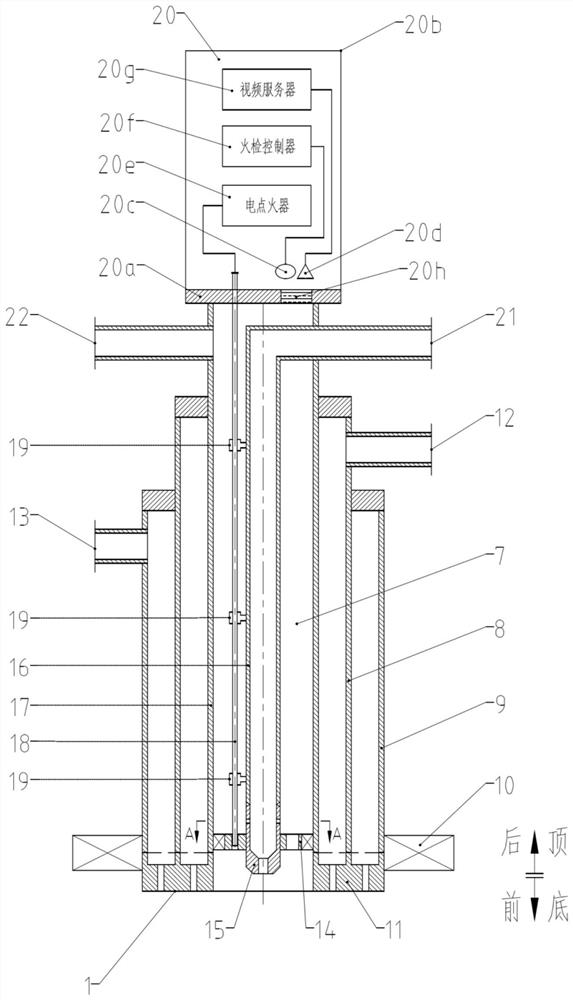

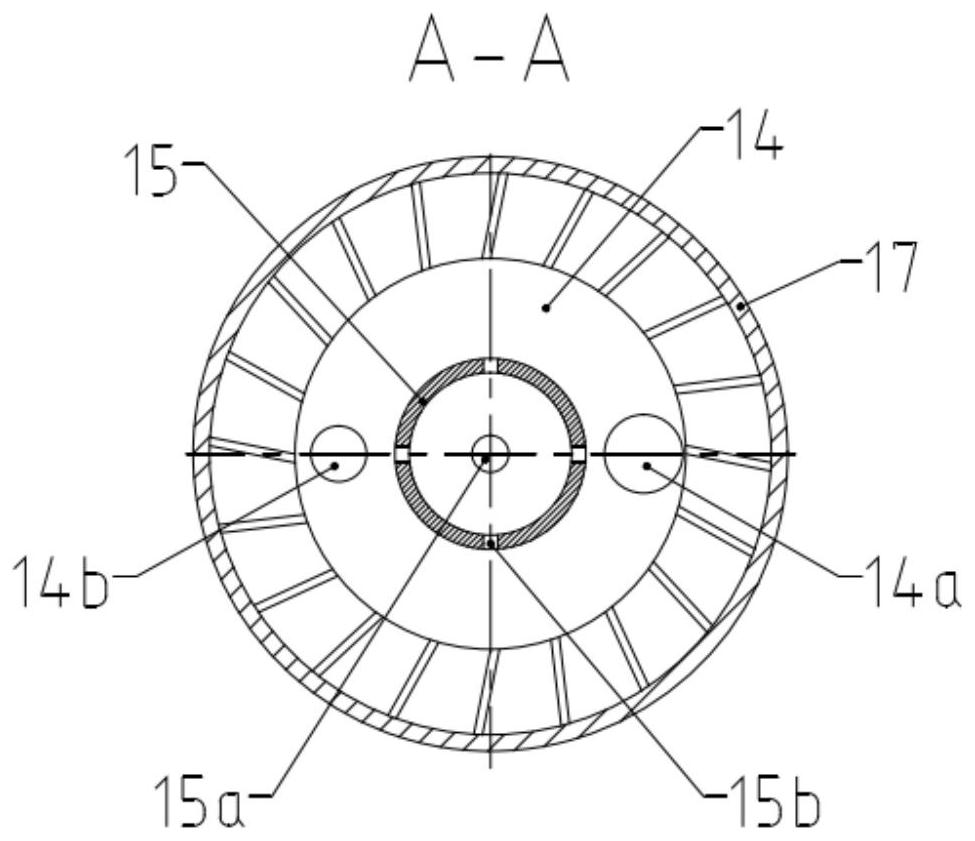

[0077] Changming lamp fuel gas entrance 21 is supplied to 1.5 nm 3 / h liquefied petroleum gas, air inlet 22 is supplied to 30nm 3 / h meter air. The first passage 8 and the outer second passage 9 in the integrated gun are supplied to the liquefied petroleum gas, and the integrated gun nozzle 11 structure is Figure 5 (A) shown in (a); 10% to 30% of the load, only the inner first passage 8 is supplied, and the outer second passage 9 starts gas when the load is 30% to 100%.

[0078] The outer gun outer diameter is 90mm, and all gasifier furnaces greater than 180 mm can be applied.

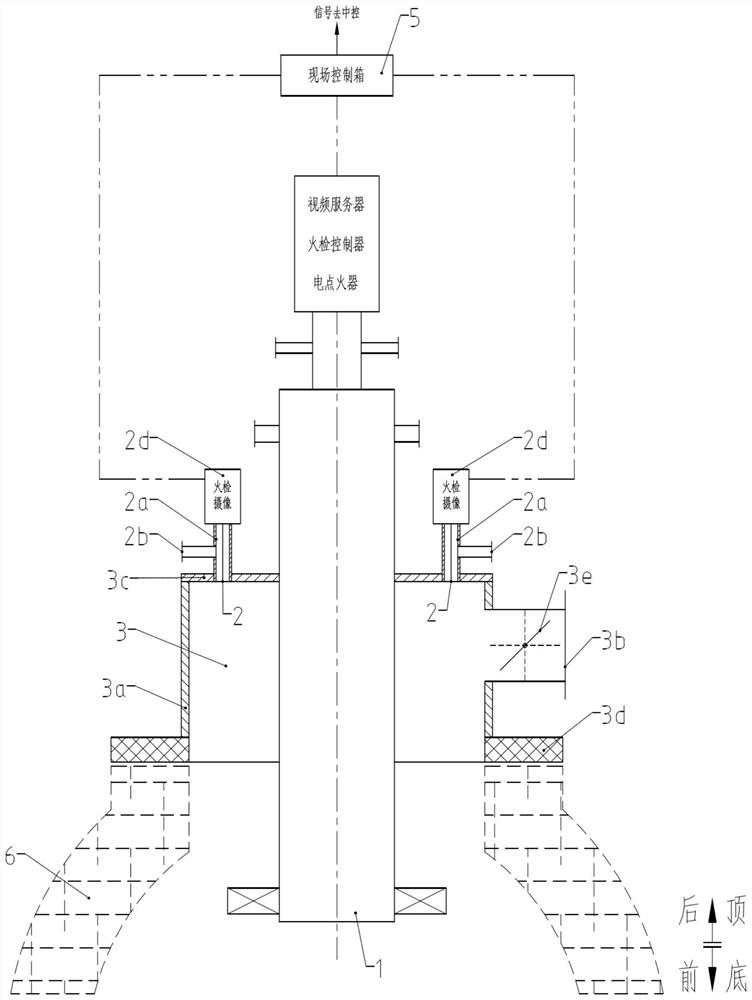

[0079] When using, the start-based burner device is first mounted to a gasification furnace burner; then the ignitio...

Embodiment 2

[0081] The technical parameters are as follows: The technical parameters are as follows:

[0082] Fuel and oxidant species - natural gas + oxygen, configuring type II burner mount

[0083] Design load - maximum natural gas 1000NM 3 / h

[0084] Changming lamp fuel gas inlet 21 is supplied 2 nm 3 / h natural gas, air inlet 22 is supplied 20nm 3 / h meter air. The first passage 8 in the integrated gun is supplied to natural gas, and the outer second passage 9 is supplied to oxygen. At this time, the integrated gun nozzle 11 structure is Figure 5 (B) shown.

[0085] When using, the start-based burner device is first mounted to a gasification furnace burner; then the ignition, load adjustment, flame detection, parking and other processes are started in the middle control room, and there is no need to operate on the spot. Operation process; finally heats the gasifier temperature to 1400 ° C. After use, the burner device is started without removing, and nitrogen gas is continuously intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com