Cylinder deformation degree correcting equipment with synchronous detection and correction

A technology of deformation degree and cylinder barrel, which is applied in the direction of measuring device, mechanical measuring device, mechanical counter/curvature measurement, etc., can solve the problems of cumbersome detection, inconvenient analysis, heavy workload, etc., achieve high accuracy of measurement data and improve product qualification efficiency and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

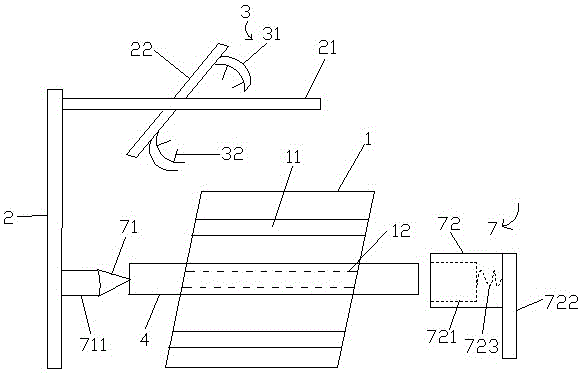

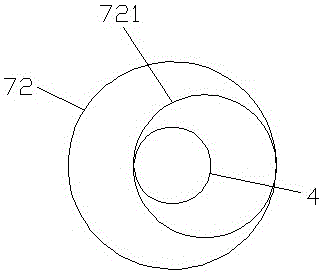

[0028] Such as figure 1 with figure 2 As shown in the figure, an oil cylinder cylinder deformation correction device that can detect and correct simultaneously, which includes a conveying track 1, an arc-shaped groove 11, a detection and correction station 12, a lifting column 2, a horizontal slide rail 21, and a cross bar 22 , coaxiality detection device 3, arc block 31, displacement sensor 32, oil cylinder barrel 4, ellipticity correction device 7, positioning plug gauge 71, telescopic cross bar 711, correction head 72, correction sleeve 721, right sliding column 722 and spring 723 and other main technical features.

[0029] The invention relates to a device for correcting the deformation degree of an oil cylinder cylinder which can be detected and corrected simultaneously, comprising a conveying track, a lifting colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com