Structural light measurement sensor calibration method

A technology for measuring sensors and calibration methods, used in measuring devices, instruments, using optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation, method, Steps, features and effects thereof are described in detail below.

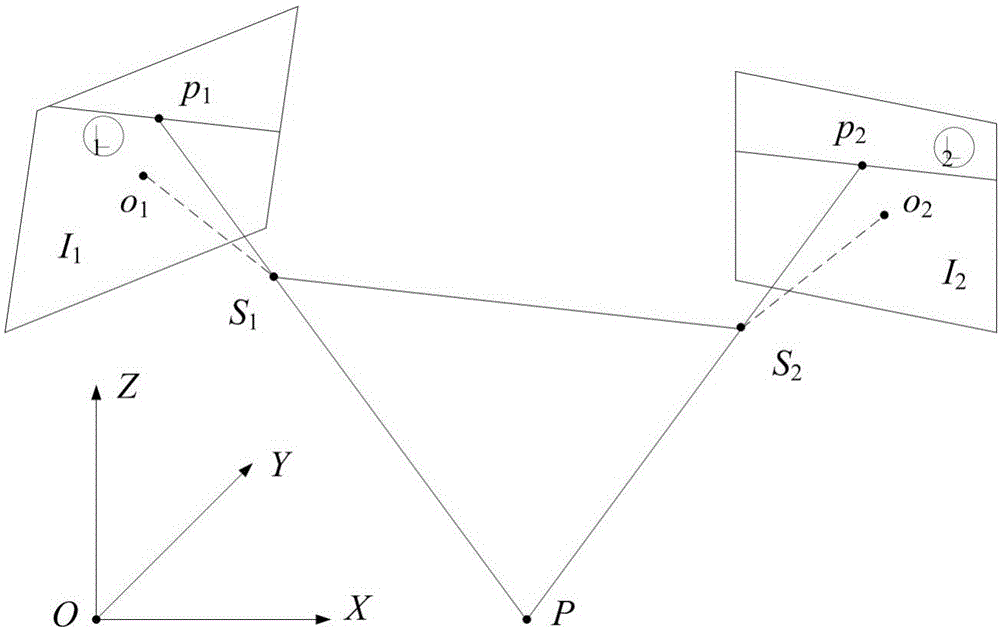

[0039] see Figure 1-4 A method for calibrating a structured light measurement sensor of the present invention comprises the following steps:

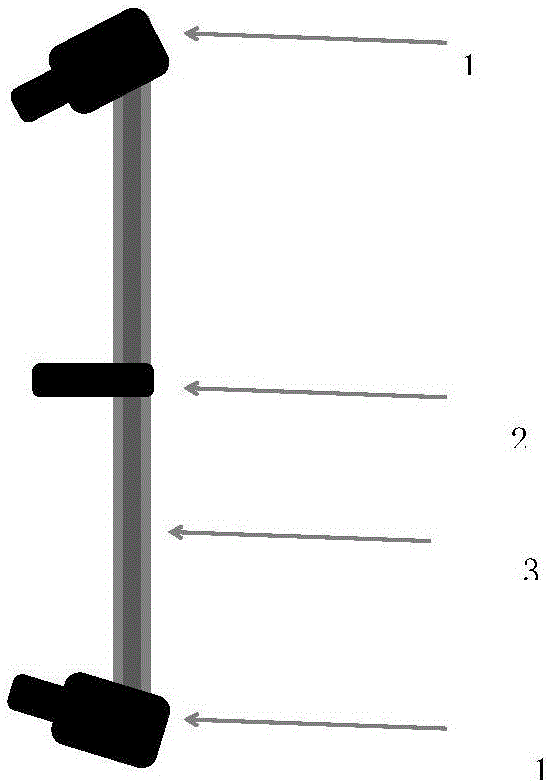

[0040] The first step is to place the target in front of the laser 2 to ensure that the laser can be projected onto the target. The two oriented cameras 1 are placed on the upper and lower parts of the laser 2 respectively, so that they can capture the laser light on the target. spot.

[0041] The second step is to control the upper and lower cameras 1 to capture target images synchronously to obtain images L1 and L2.

[0042] The third step is to process the images L1 and L2 respectively, and extract the center coordinates of the light spot on the image. The specific processing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com