Anchor pull-out test system for rammed earth relics

A test system and technology of earth ruins, applied in the field of anchor pullout test system of rammed earth ruins group, can solve problems such as insufficient reinforcement, over reinforcement, and failure to reflect, and achieve the effect of preventing uneven stress distribution and solving ground unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

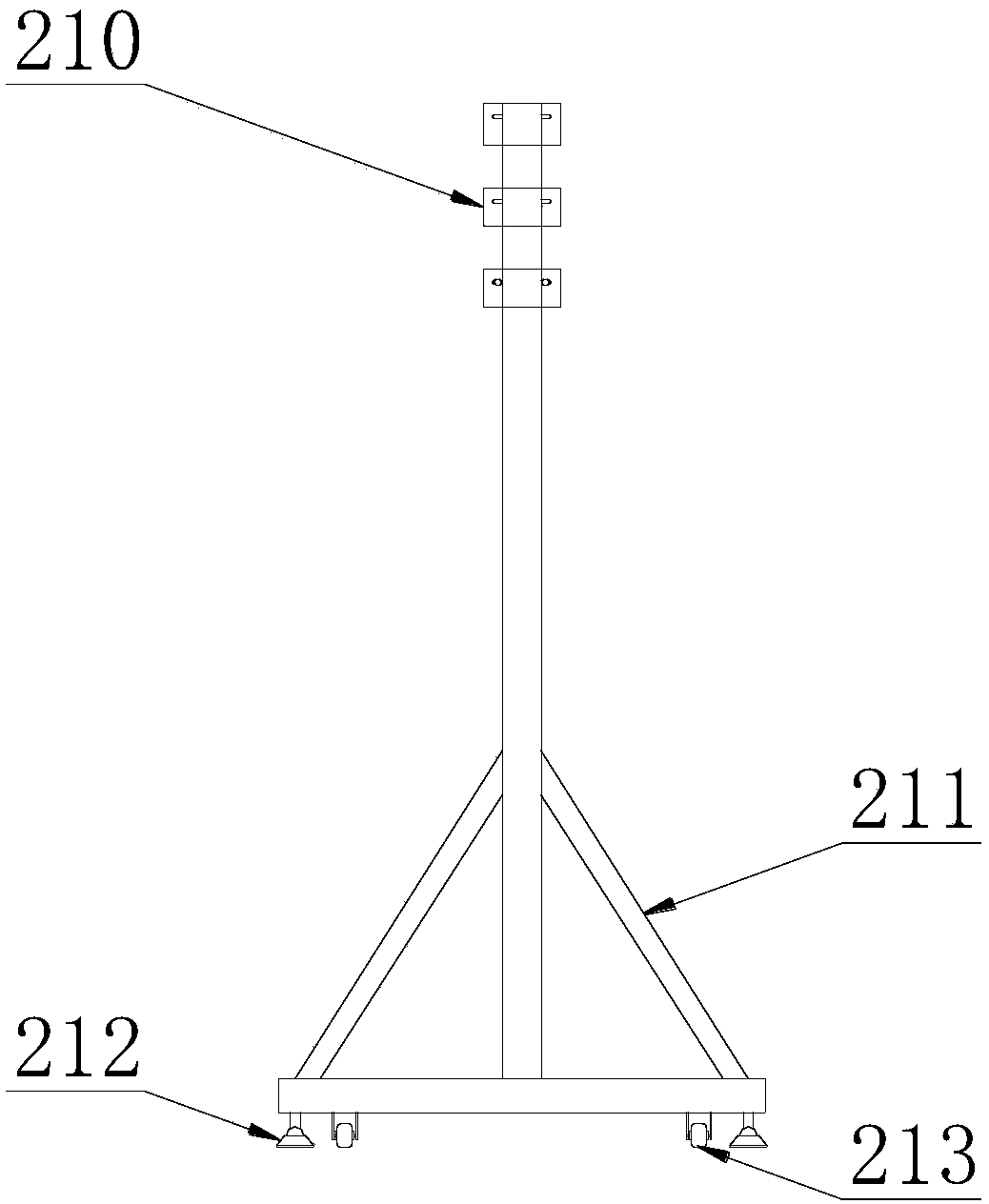

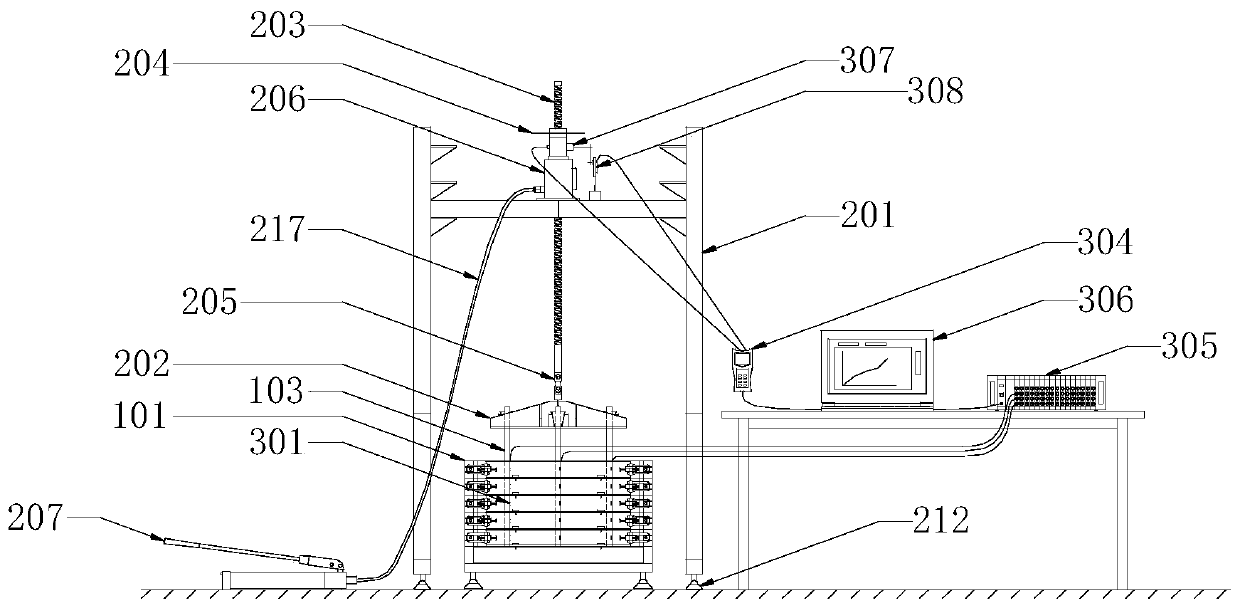

[0052] Such as figure 1 As shown, the present invention provides a group anchor pullout test system for rammed earth sites, including a group anchor mechanism, a loading mechanism, and a data acquisition and processing system.

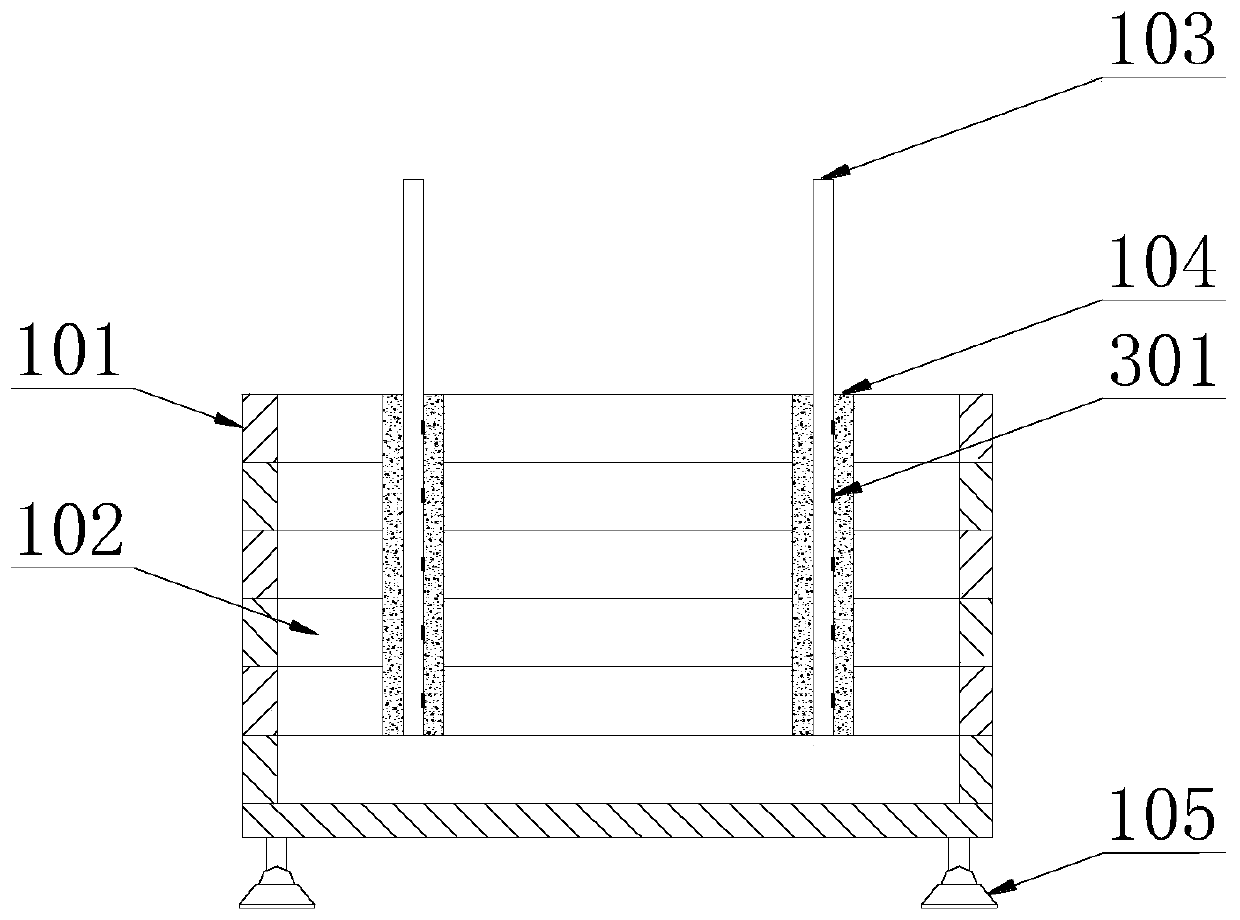

[0053] see also figure 2 , the group anchor anchoring mechanism includes a rammed earth box 101, a rammed earth layer 102 is rammed in the rammed earth box 101, 2-4 anchor holes are arranged in the rammed earth layer 102, and these anchor holes are relative to the rammed earth The central axes of the layers 102 are evenly arranged at equal intervals. An anchor rod 103 for testing is arranged in each anchor hole, and an anchor grout 104 is arranged between the anchor rod 103 and the anchor hole to securely connect the rammed earth layer 102 to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com