Optical waveguide display module, electronic equipment and making method

A technology for display modules and manufacturing methods, which is applied in the direction of light guides, electronic equipment, chemical instruments and methods, etc., can solve the problems of low original light intensity, destroying the conditions of total reflection of light, and inability to pass through the light waveguide, etc., so as to improve the uniformity of display performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

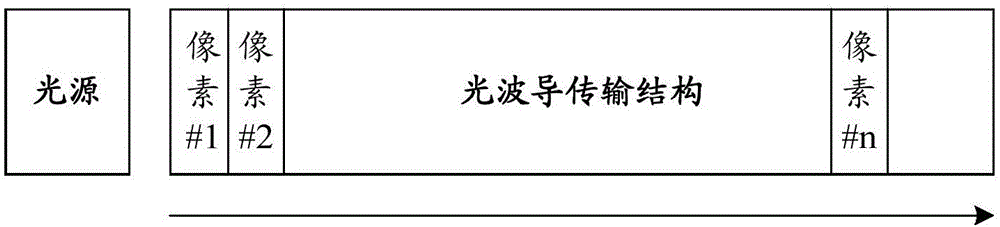

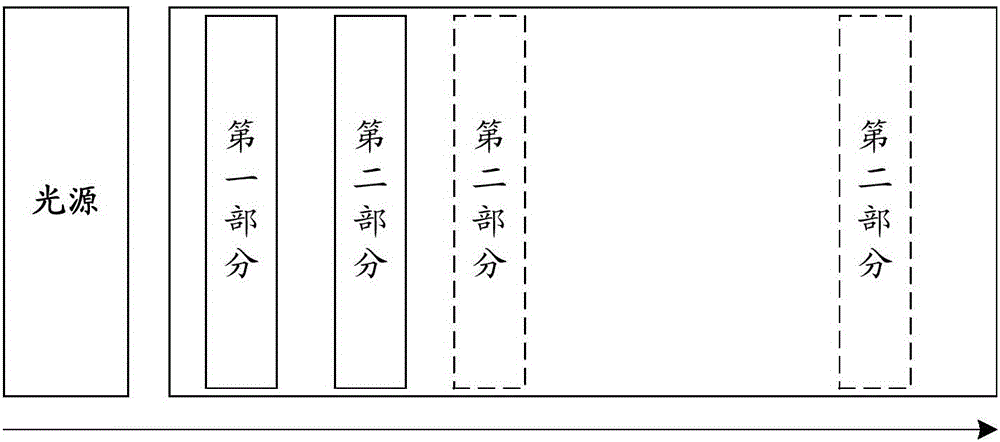

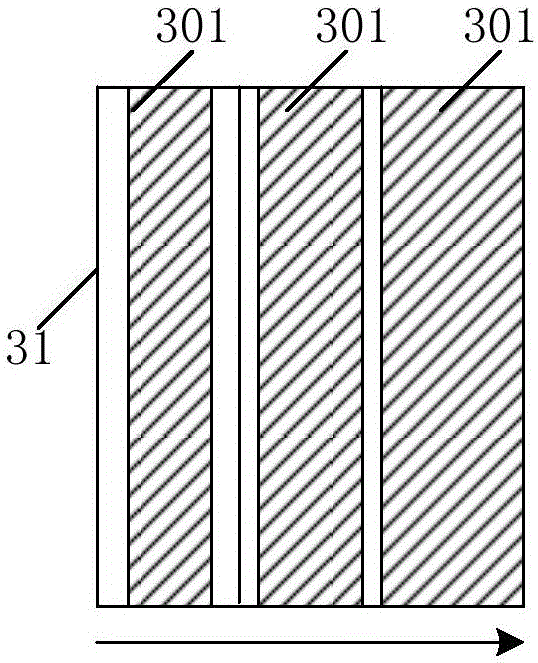

[0044] In the specific embodiment of the present invention, the scattering ability of the optical waveguide display module is designed according to the distance from the light source. The ability to destroy the total reflection condition), so as to make up for the display non-uniformity problem caused by light attenuation, and improve the display uniformity performance of the display module.

[0045] The optical waveguide display module according to the specific embodiment of the present invention has a display area, wherein the display area of the optical waveguide display module includes two areas with the same area, and the voltage of the electrical signal applied to the pixel electrode is equal to At the same time, the scattering ability of the first part of the optical waveguide display module is weaker than that of the second part of the optical waveguide display module, such as figure 2 As shown, the first part of the optical waveguide display module is the part corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com