Method for vehicle remote diagnosis and spare parts retrieval

A technology of remote diagnosis and spare parts, applied in the field of information retrieval, can solve problems such as differences in group numbers, and achieve the effect of solving the problem of experience limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

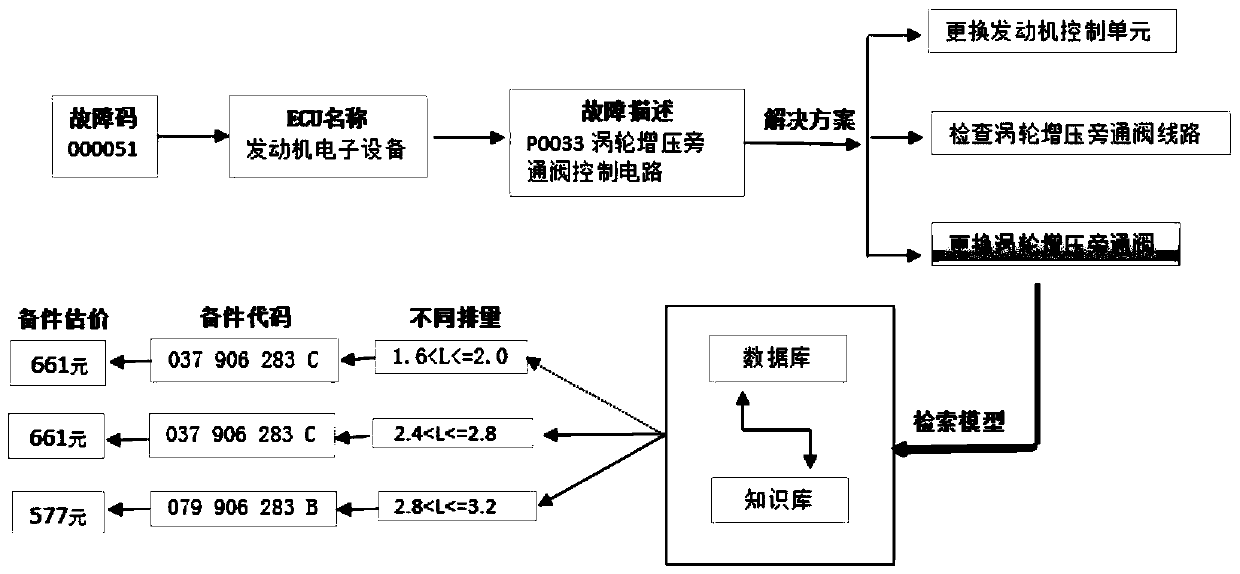

[0014] Embodiment 1: A method for vehicle remote diagnosis and spare parts retrieval: such as figure 1 shown, including the following steps:

[0015] Step 1. Collect vehicle information data;

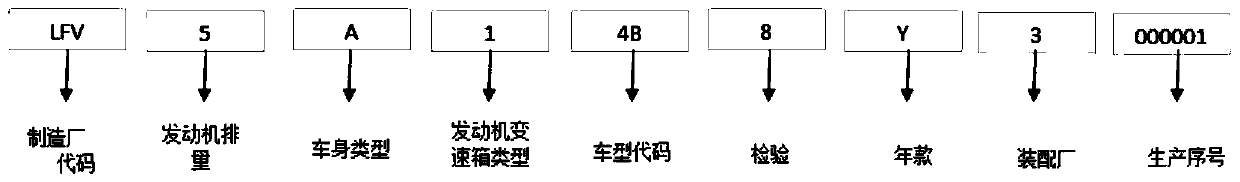

[0016] Step 2. Analyze the vehicle VIN code to obtain variables, the variables include the engine displacement, body type, and engine gearbox type obtained by the VIN code analysis; through the vehicle chassis number (17-digit VIN code), translate each number to represent Relevant information (variables) to form a rich data knowledge base, such as the translation rules for each number of a vehicle with a chassis number of LFV5A14B8Y3000001 such as figure 2 shown.

[0017] Step 3. Perform a decision tree analysis on the spare part codes corresponding to the variables, complete the classification of variable data to form spare part information, and establish an index to form a diagnostic knowledge base;

[0018] Step 4. For the historical vehicle fault data, count and record the work ...

Embodiment 2

[0022] Embodiment 2: have the technical scheme identical with embodiment 1, more specifically:

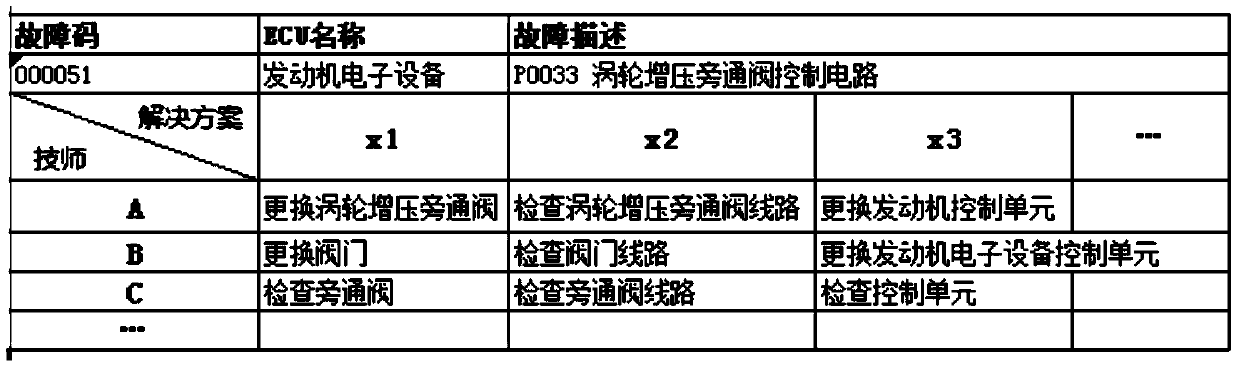

[0023] In the step 3, the historical records of the maintenance spare parts table are used as the data basis, and the spare parts are classified through the decision tree model, and the maintenance spare parts table sample is shown in Table 1:

[0024] Table I

[0025] VIN123 VIN4 VIN6 VIN78 BJDM LFV 5 1 4B 06J115403J LFV 3 2 8K LN052167A21 LFV 4 2 4F LN052167A24

[0026] The basic principles of the decision tree model are as follows:

[0027] First: Determine the entropy of different categories of spare parts in each dimension. Taking VIN4 as an example, the entropy is defined as

[0028] E=sum(-p(I)*log(p(I)))

[0029] Wherein I=1:N (N category results, such as this example 1, that is, the spare part belongs to this model, so the probability P(I)=1)

[0030] Then E(5)=-(1 / 1) Log2(1 / 1)-(0 / 1) Log2(0 / 1)=0+0=0

[0031] E(3)=-(1...

Embodiment 3

[0050] Embodiment 3: have the technical scheme identical with embodiment 1 or 2, more specifically:

[0051] In the fourth step, using variance analysis to simulate the technician's diagnostic thinking, the steps to obtain the best solution under the fault code are:

[0052] (1) According to the personal experience and different ways of thinking of different technicians, check the solutions given by each fault description and the information of the work items and spare parts used;

[0053] (2) Quantify the diagnostic data given by all technicians;

[0054] (3) Then use analysis of variance to compare, and compare the difference between the answers between the two;

[0055] (4) According to the difference results, the solution with the smallest difference is selected as the final solution of the fault code.

[0056] Through the above methods, a relatively complete data knowledge base is formed from fault code → solution → spare parts information.

[0057] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com