Penetration prediction and control method and system for laser welding of variable-thickness section plate

A laser welding and panel technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as burn-through, lack of fusion, and coarse weld structure, and achieve high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

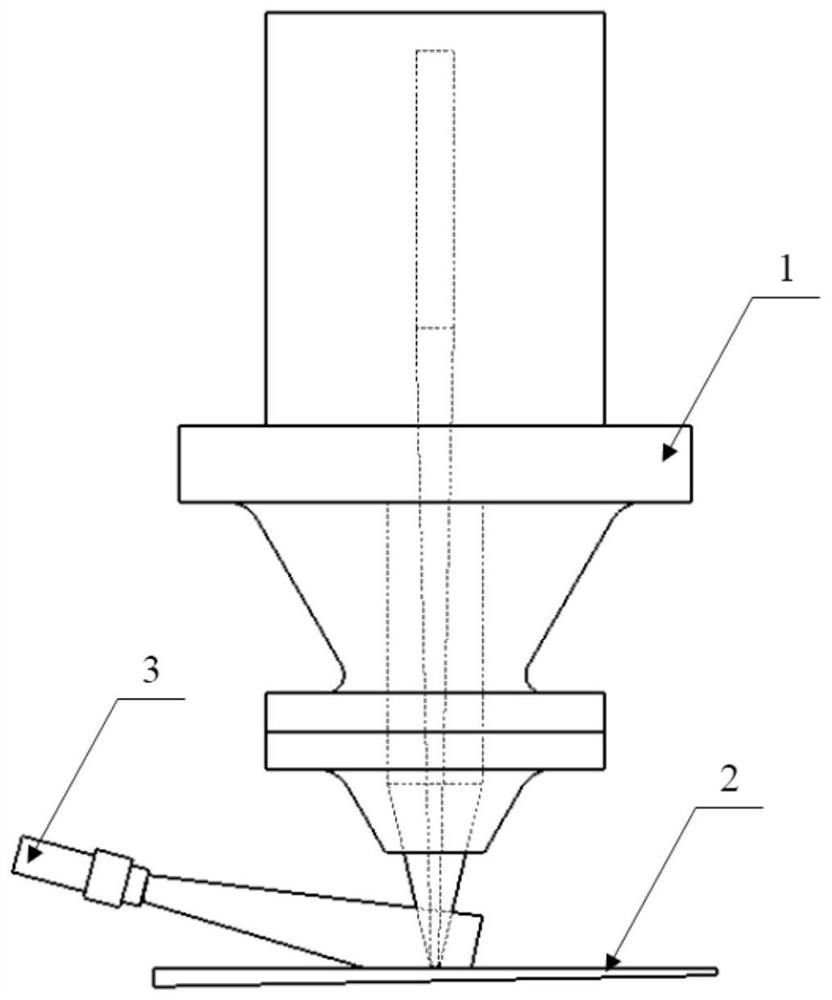

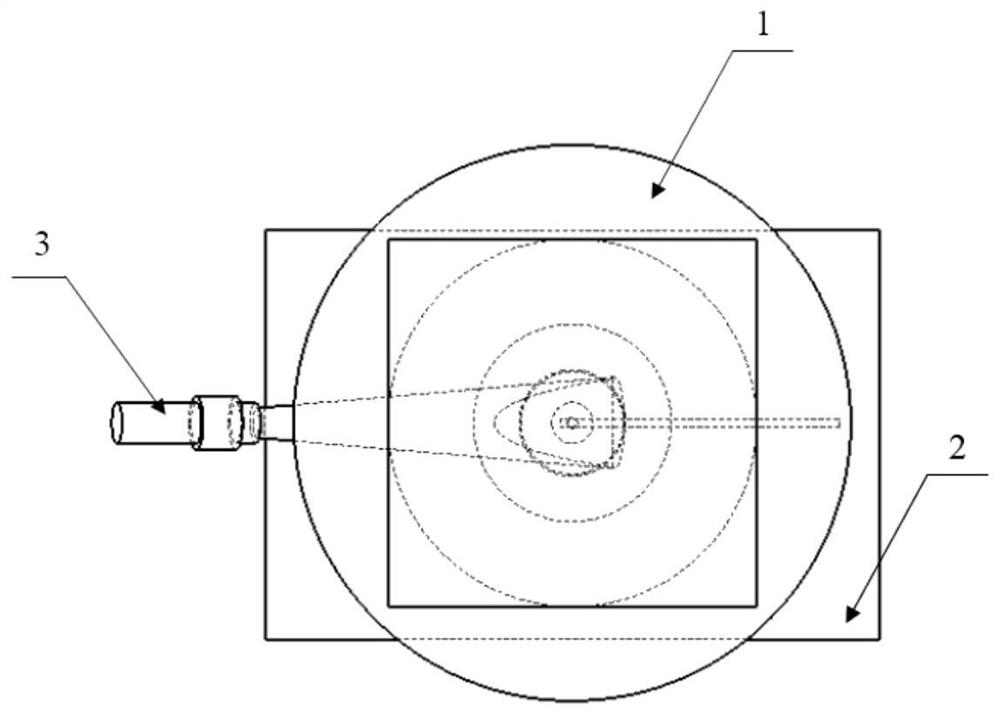

Method used

Image

Examples

Embodiment 1

[0054] Here, the variable-thickness cross-section plate steel produced by Baosteel Group Co., Ltd. is taken as the research object to further illustrate the principle of the present invention. The steel type of the specimen is B340LA, and its chemical composition is shown in Table 1. The size of the welded test piece is 240mm×30mm, and the thickness varies from 1.2mm to 2.0mm. Shot blasting is performed on the welding surface before the test. Removing oxides on the surface of the material can also increase the surface roughness, reduce the reflection of the material to the laser, and improve the absorption rate of the material to the laser.

[0055] Table 1 B340LA steel chemical composition (mass fraction, %)

[0056]

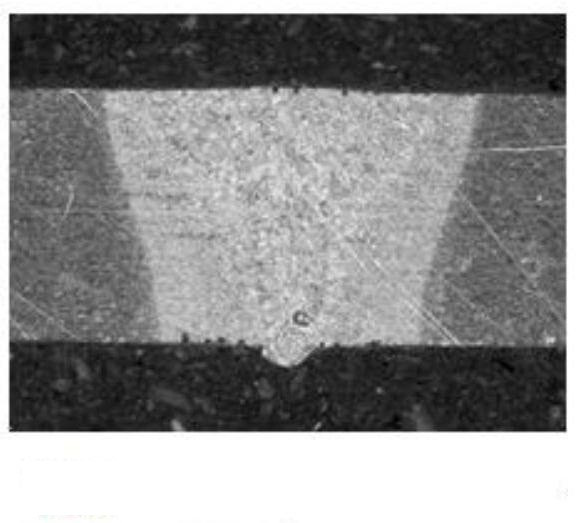

[0057] When the laser power is 800w, the 1.2mm thick area is not penetrated; when the laser power is 1700w, the 2mm thick area has collapse defects. Therefore, welding is carried out with the technological parameters of laser power 800-1700w, welding speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com