Direct-current charging pile

A technology of DC charging pile and charging grab, which is applied to charging stations for charging mobile devices, current collectors, electric vehicles, etc. Operation safety, saving charging cost, good isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

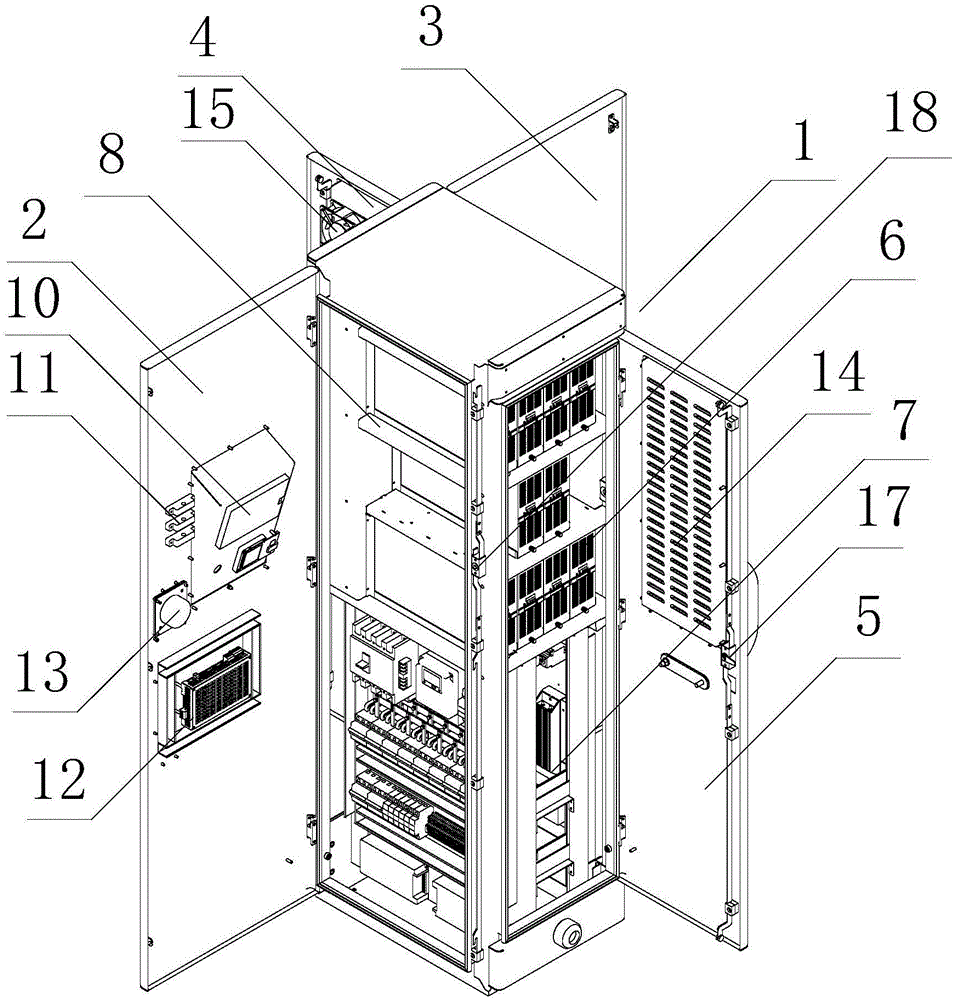

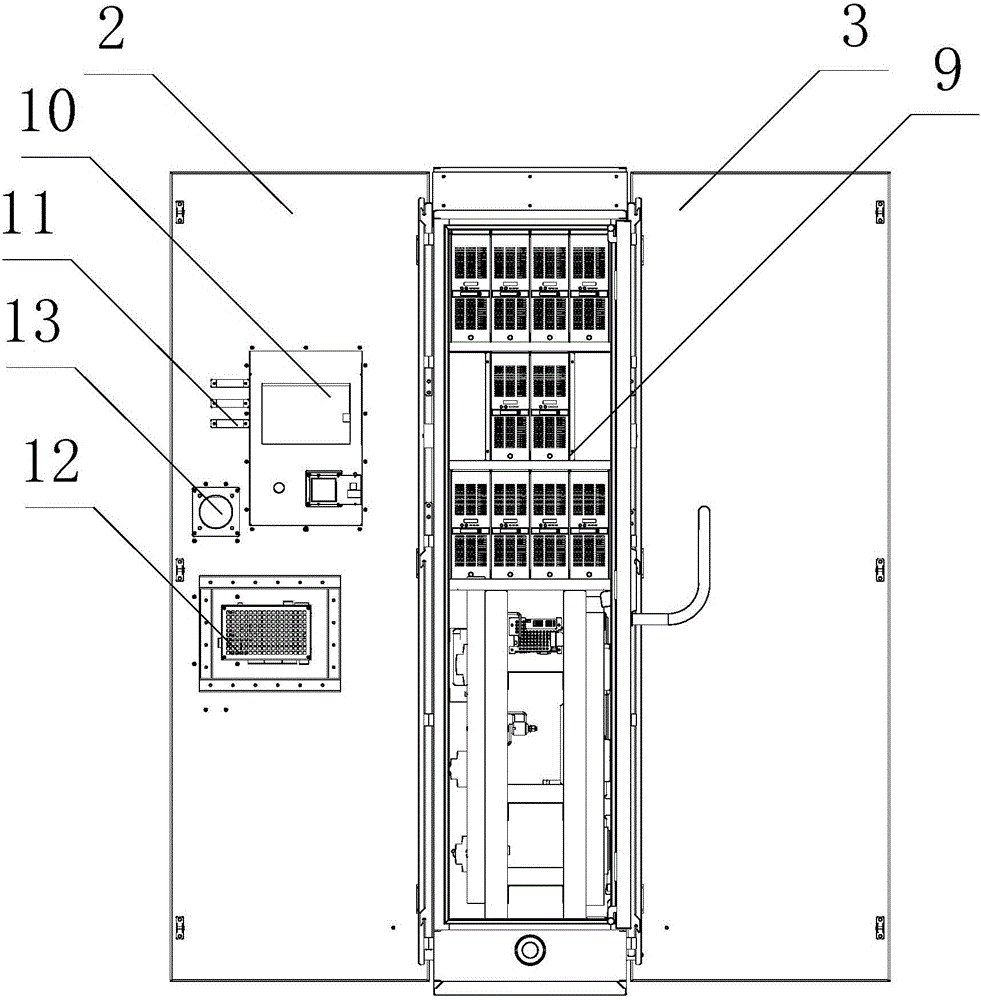

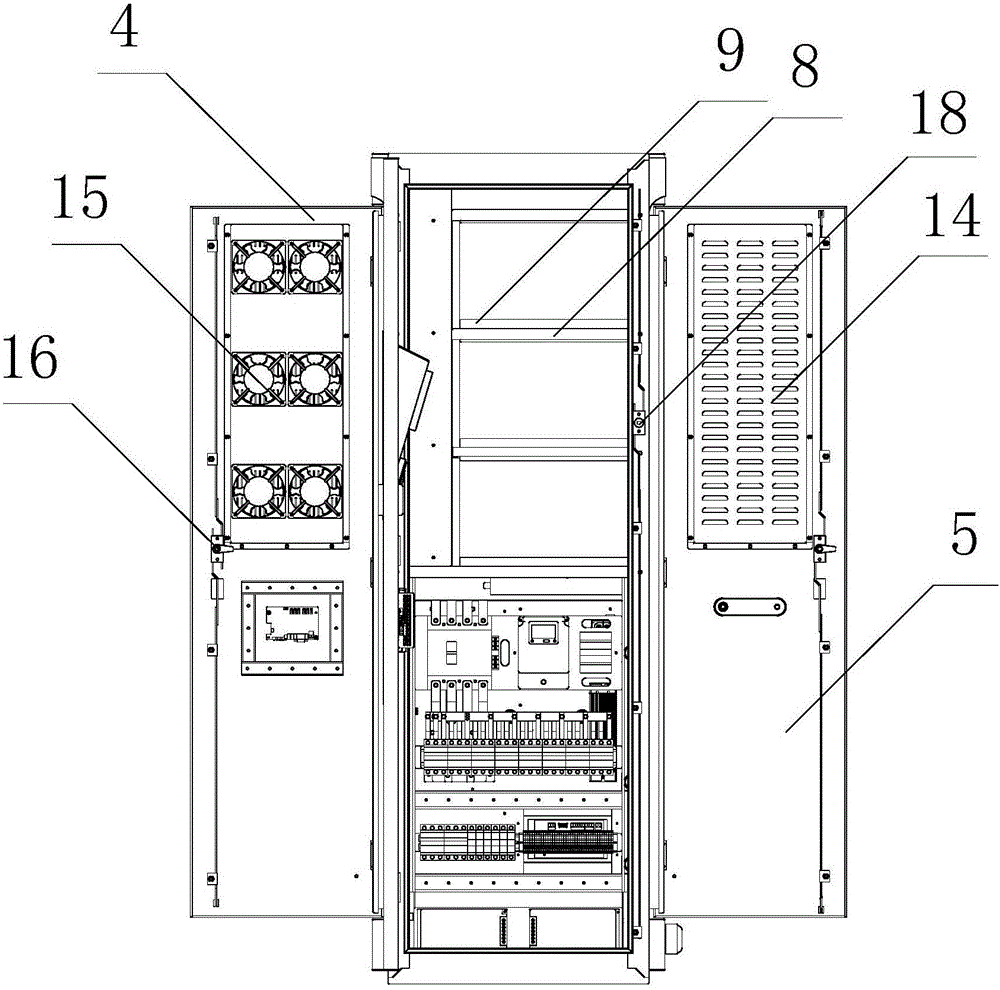

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0036] Such as Figures 1 to 5 As shown, a DC charging pile includes a cabinet body 1 with a rectangular parallelepiped frame structure, and the front, rear, left and right sides of the cabinet body 1 are respectively provided with front cabinet doors 2, Back cabinet door 3, left cabinet door 4 and right cabinet door 5.

[0037] The cabinet 1 is provided with a rectification chamber 6 and a control chamber 7, the rectification chamber 6 is located in the upper part of the cabinet 1, and the rectification chamber 6 is provided with a rectification module, and the control chamber 7 is located in the The lower part of the cabinet body 1, and the control room 7 is provided with primary control equipment and outgoing bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com