Motor shell and low-vibration motor comprising same

A motor casing and motor technology, applied in the field of motors, can solve the problems of high noise, strong vibration and low reliability of the motor, and achieve the effects of low noise, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

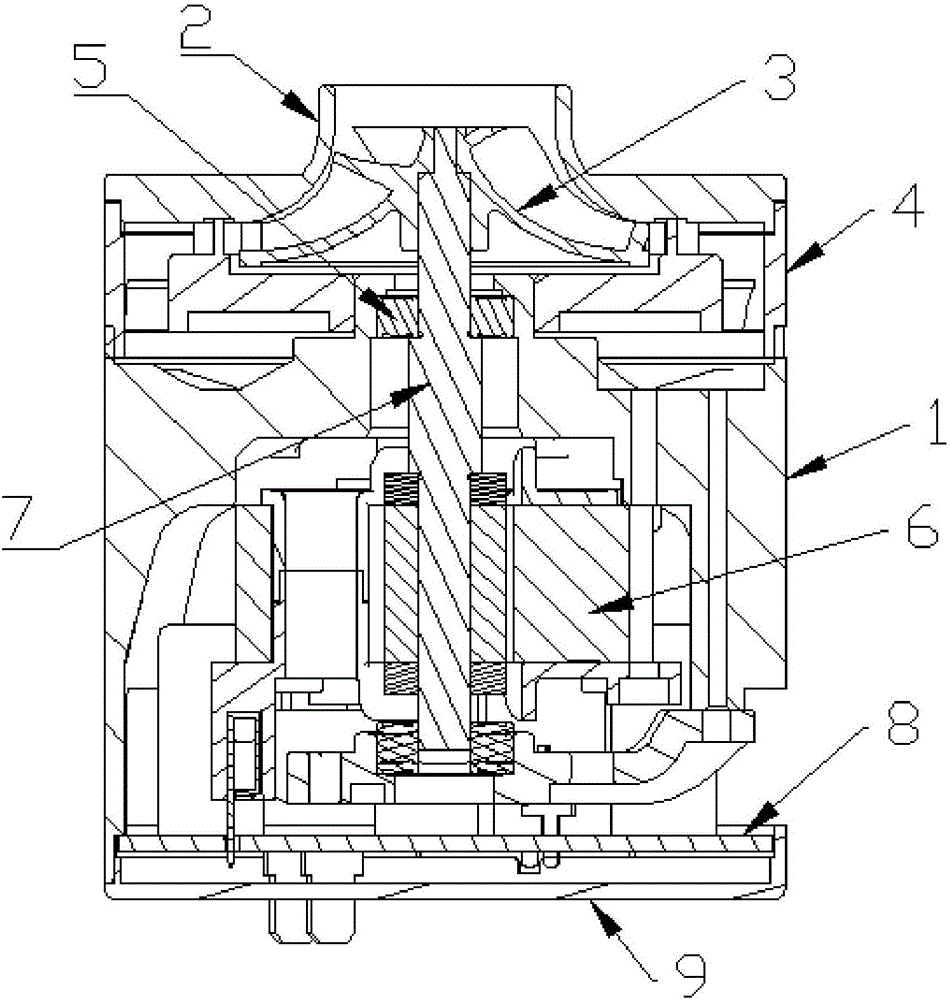

[0054] To achieve the object of the present invention, in some embodiments of the motor housing and the low vibration motor including the housing,

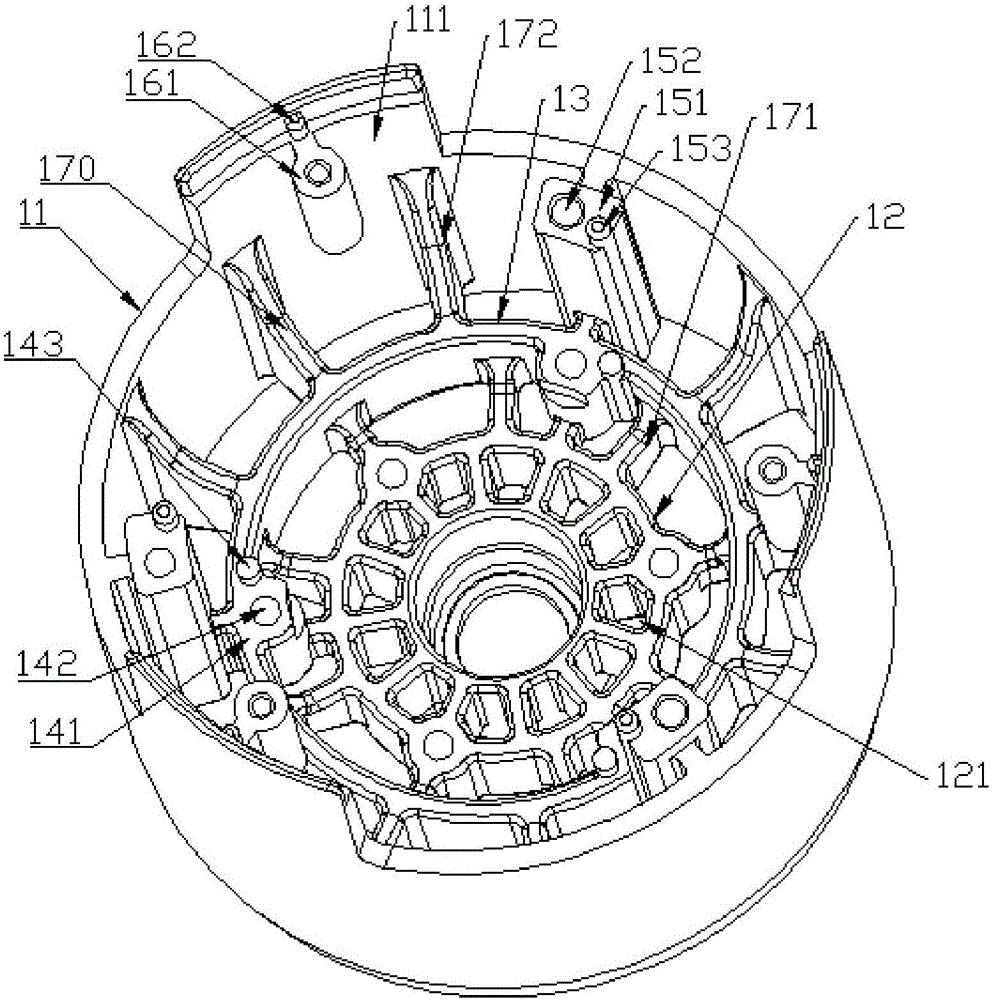

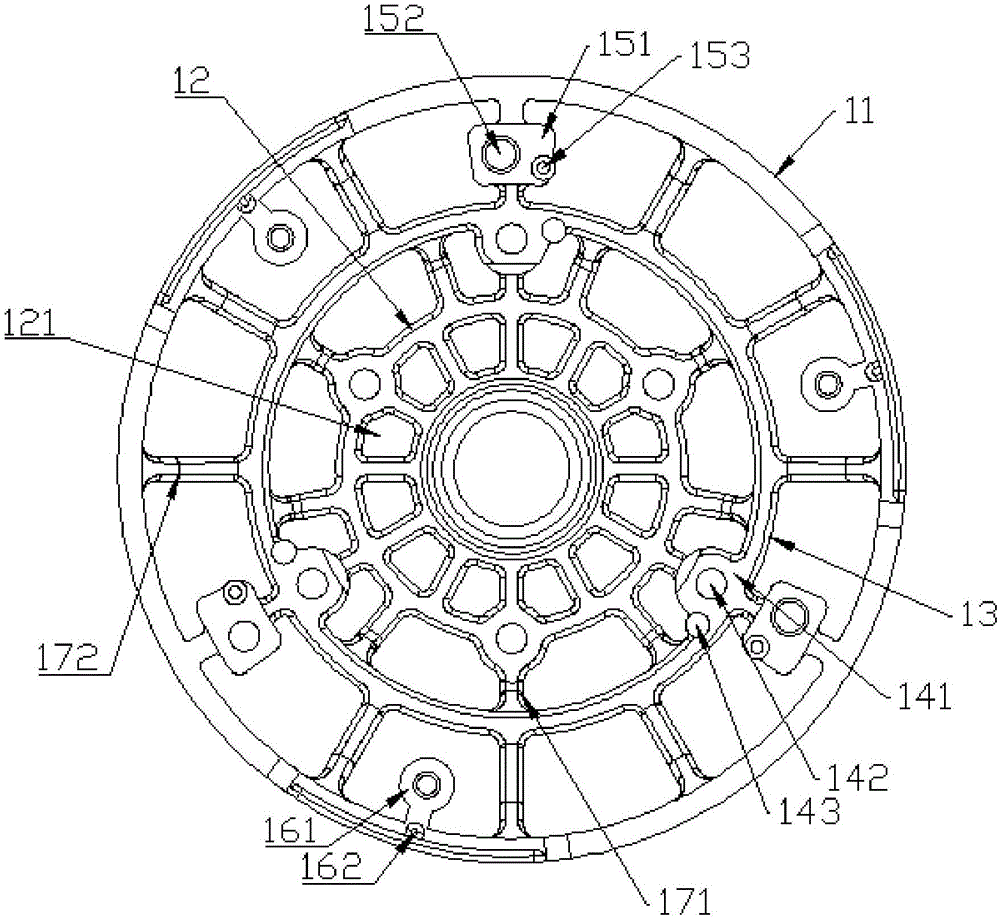

[0055] Such as Figure 1-2 As shown, the motor casing 1 includes: a housing 11 , a first circular support portion 12 , a second circular support portion 13 , a first positioning component 14 , a second positioning component 15 and a third positioning component 16 .

[0056] The housing 11 is a circular cylinder that penetrates up and down and has a cavity inside. There are three extensions 111 extending outward along the axial direction of the housing 11. The three extensions are centered around the center of the housing 11 along the circumference of the housing 11 Evenly distributed, the gaps provided between adjacent extensions 111 are convenient for heat dissipation of the motor components in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap