Motor heat dissipation structure

A technology of motor heat dissipation and permanent magnet motor, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve the problems of reducing heat conduction efficiency, affecting heat dissipation effect, and increasing motor noise, so as to shorten the heat conduction path and improve heat dissipation effect, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

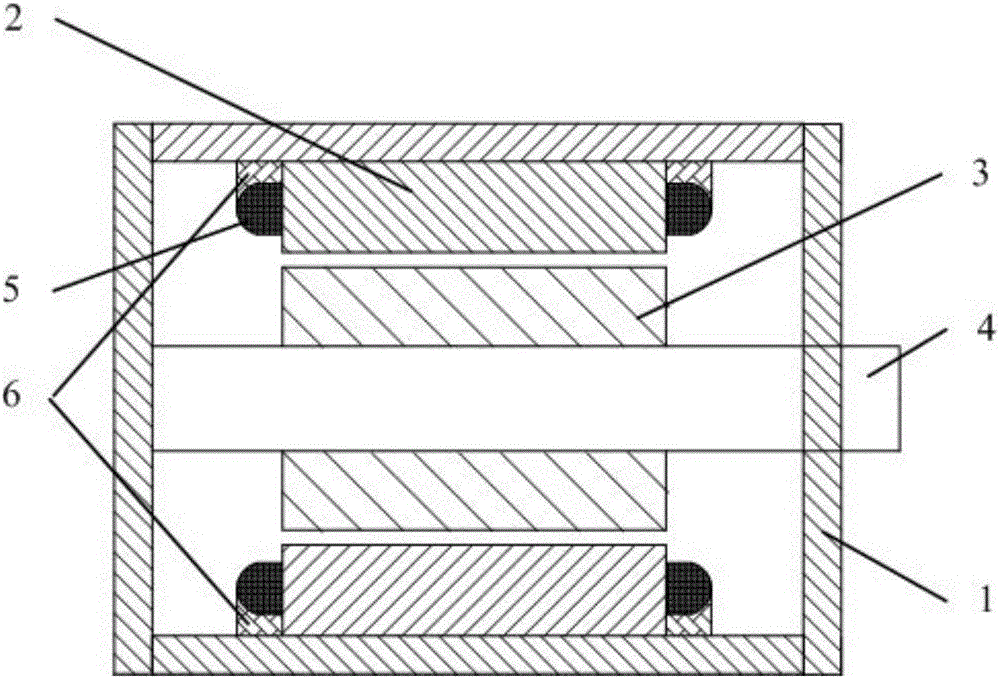

[0018] Such as figure 1 Shown is a schematic diagram of the heat dissipation structure of the motor of the present invention. The motor includes a casing 1, a stator 2, a rotor 3, a motor shaft 4, and a coil 5. Most of the heat generated by the rotor 3 and the motor shaft 4 during operation is It is transmitted to the stator 2 through other media such as air or oil, and is transmitted to the casing 1 by the stator 2 to dissipate heat. For the stator 2 itself, its main heating element is the coil 5, while the traditional The heat dissipation path of the motor stator is: coil, skeleton, stator core, and casing, and there is an air gap in the above path, that is, there is a need to transfer heat through air between adjacent components. Such a heat dissipation path is too long and the efficiency is low, and When the heat generated by the rotor of the motor is transferred to the stator, the heat of the stator is often large and the heat dissipation is not timely. In order to solve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com