Alternating current capacitor motor with starting operating characteristic of direct current motor

A technology of operating characteristics and DC motors, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of high manufacturing cost, many consumables, large volume, etc., and achieve the effect of compact and reasonable structure combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

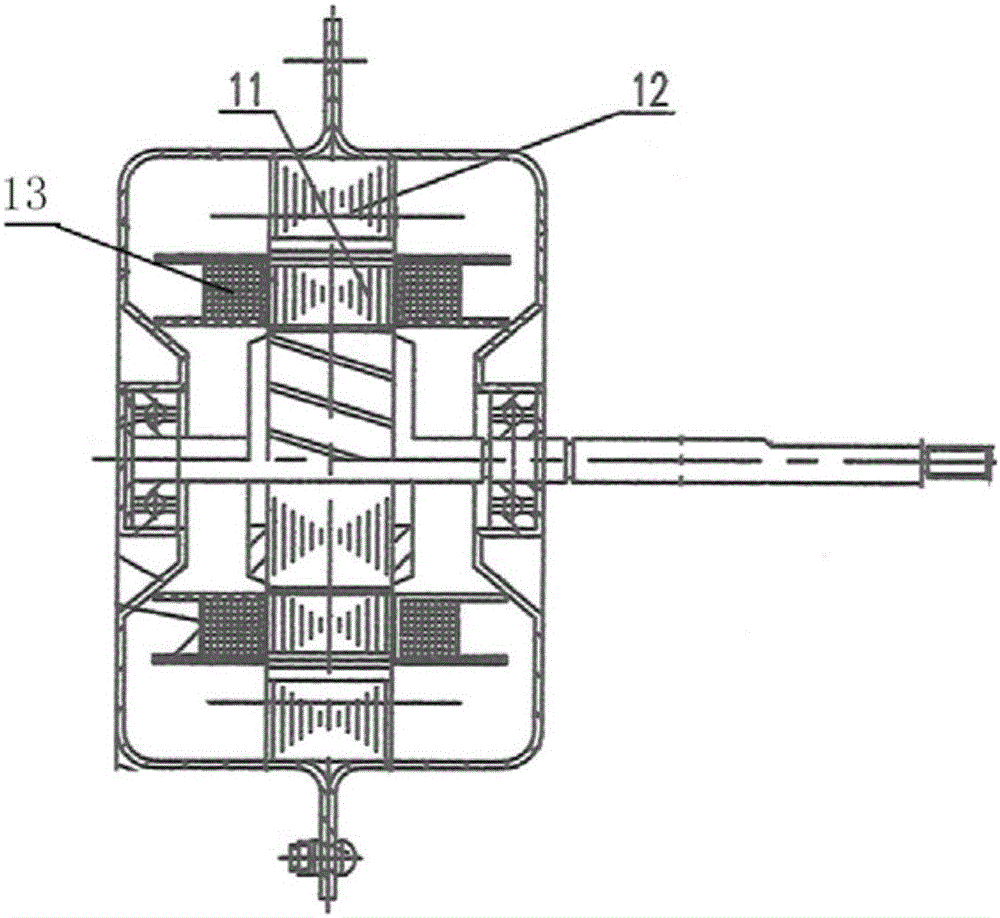

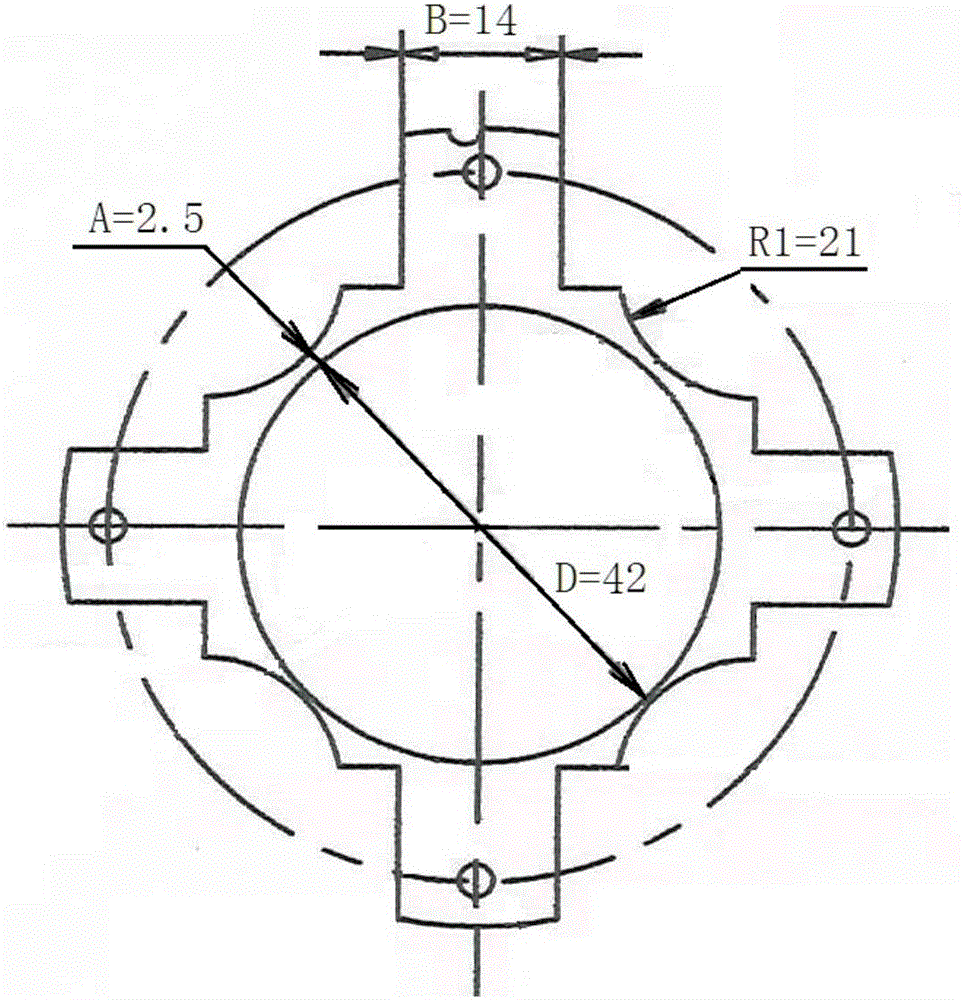

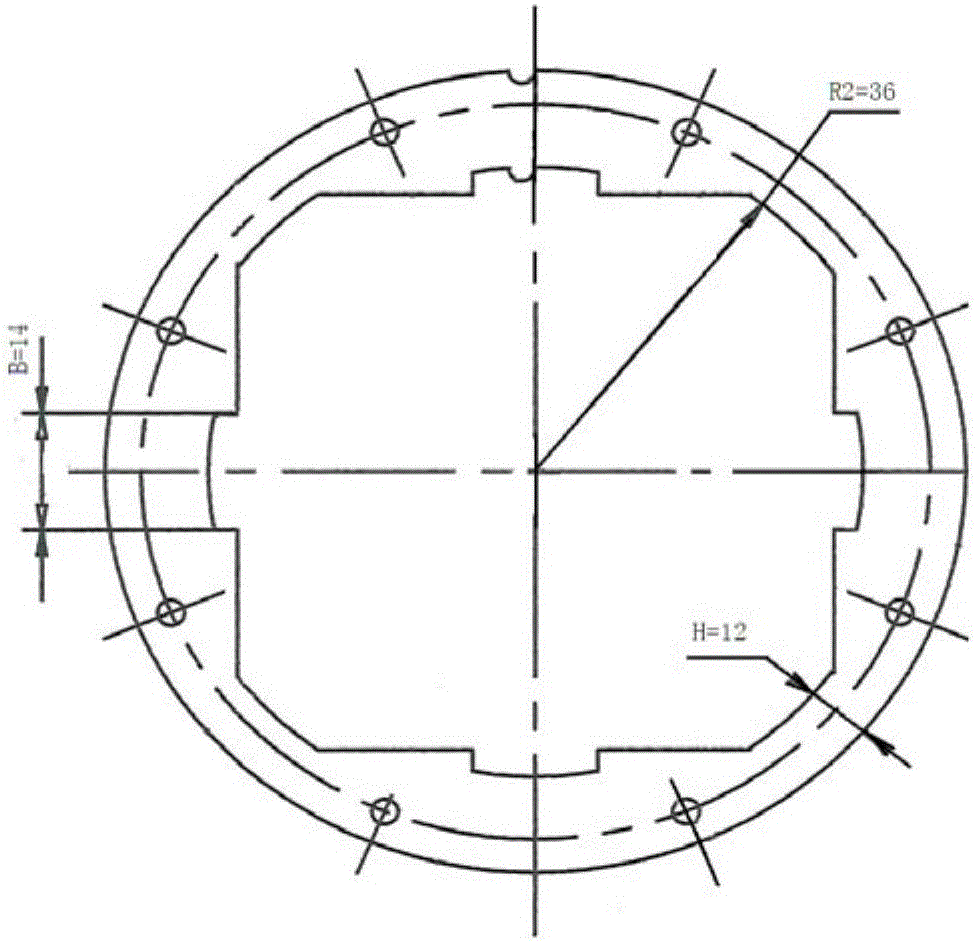

[0024] The AC capacitor motor with DC motor starting and running characteristics of the present invention includes a stator, a rotor and a capacitor. see figure 1 , the stator includes an inner stator core 11 , an outer stator core 12 and a winding coil 13 . The rotor is installed in the inner core 11 of the stator. The inner iron core 11 of the stator is provided with a salient magnetic pole body, and the winding coil 13 is sleeved on the salient magnetic pole body, and is installed in the outer iron core 12 of the stator together with the inner iron core 11 of the stator. see figure 2 , the winding coil 13 includes a primary winding and a secondary winding. After the capacitor is connected in series with the secondary winding, it is connected to the power supply in parallel with the primary winding.

[0025] see figure 2 , The inner iron core 11 of the stator is formed by stacking a group of convex magnetic pole pieces, and the inner edge of the convex magnetic pole pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com