An improved sliding form system inner and outer formwork supporting and fastening structure

A technology of fastening structure and formwork support, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building structure, etc. problems, to achieve the effects of improving stability, adjusting the angle of mold collection and flatness of the template, and increasing the friction surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

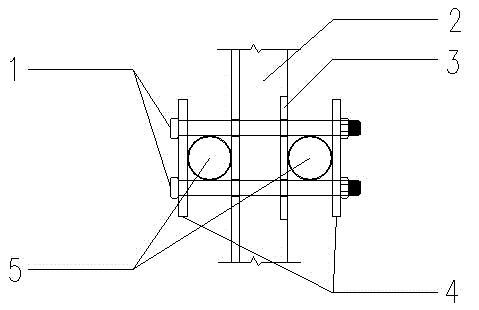

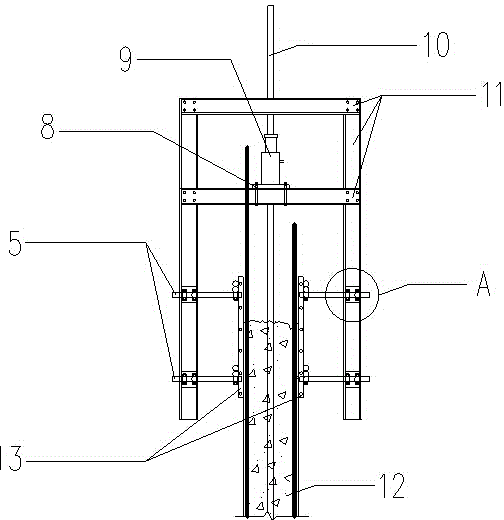

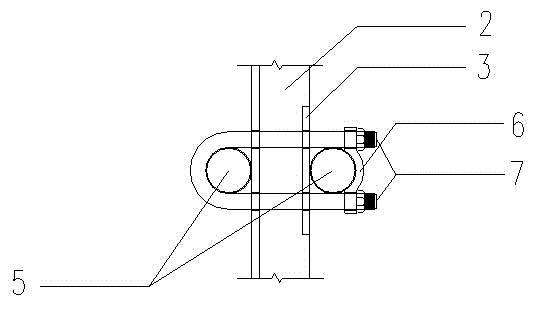

[0023] see now figure 2 and image 3 , figure 2 It is a schematic diagram of the fastening structure of the portal frame and the climbing system according to the embodiment of the present invention, image 3 for figure 2 Enlarged view of part A in . As shown in the figure, the portal frame 11 is connected with the climbing rod 10 through a hydraulic jack 8; The two sides of the vertical wall structure 12; the supporting fastening structure includes M16 U-shaped bolts 7 and 6mm thick semi-circular arc cast iron buckles 6; when assembling the inner and outer formwork, the U-shaped bolts are first passed through the portal frame channel steel, and then the two The root supporting steel pipe 5 is penetrated into the U-shaped bolt, and the steel pipe 5 is a steel pipe with a diameter of 48*3.5 mm, so that the semi-circular arc at one end of the U-shaped bolt is tightly hooped to a steel pipe 5, and the other end of the U-shaped bolt is installed with a buckle 6 to tighten it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com