Worm and gear drive mechanism and worm and gear speed reducer

A technology of worm gear and transmission structure, which is applied to transmission parts, mechanical equipment, belts/chains/gears, etc. It can solve problems such as poor transmission, changes in transmission speed ratio, and decreased meshing accuracy of worm gear transmission, and achieves the elimination of fixed-point meshing Poor state, guarantee the tightness of cooperation, and the effect of filling the gap in the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

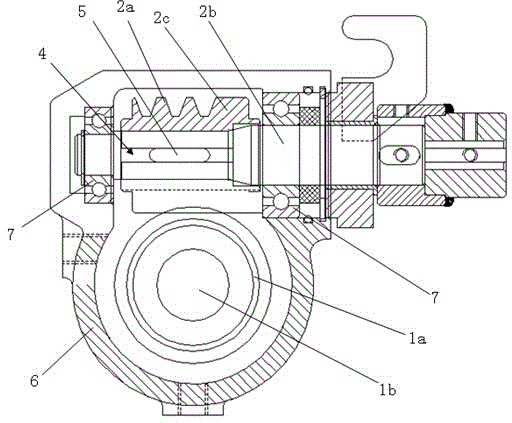

[0019] The present invention will be described in detail below with reference to the drawings and examples.

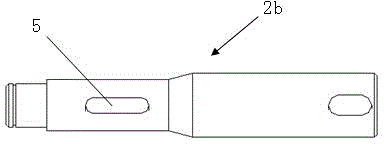

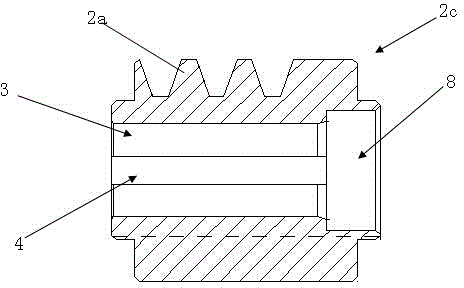

[0020] figure 1 It is a schematic diagram of the worm shaft in the worm gear transmission structure of the present invention; figure 2 It is a schematic diagram of the gear rod in the worm gear transmission structure of the present invention; image 3 It is a schematic diagram of the worm gear reducer adopting the worm gear transmission structure of the present invention.

[0021] Such as Figure 1 to Figure 3 As shown, the worm gear transmission structure of the present invention includes a worm wheel 1 and a worm screw 2, wherein the worm wheel includes a toothed disc 1a and a worm shaft 1b coaxially arranged, the worm wheel shaft and the toothed disc are coaxially arranged and rotate synchronously, and the worm includes a helical tooth 2a And the worm shaft 2b, the toothed disc and the worm are vertically arranged, the toothed disc and the helical teeth mesh wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com