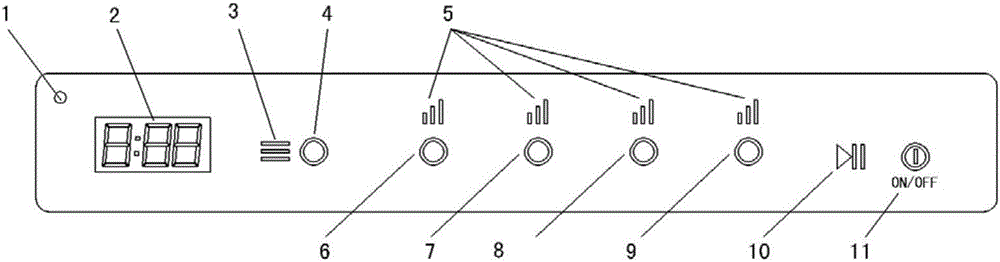

Operation panel

An operation panel and operator technology, applied in the washing machine/washing machine of tableware, cleaning equipment, household utensils, etc., can solve the problems of different washing intensity, water level setting, different washing time, different washing time, etc., and reduce the number of buttons. The number of operations and logic complexity, low cost, reasonable layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] An operation panel, applied to a sink type or a cabinet type washing device, comprising: a control part, used for customizing the selected button

[0020] mode switching;

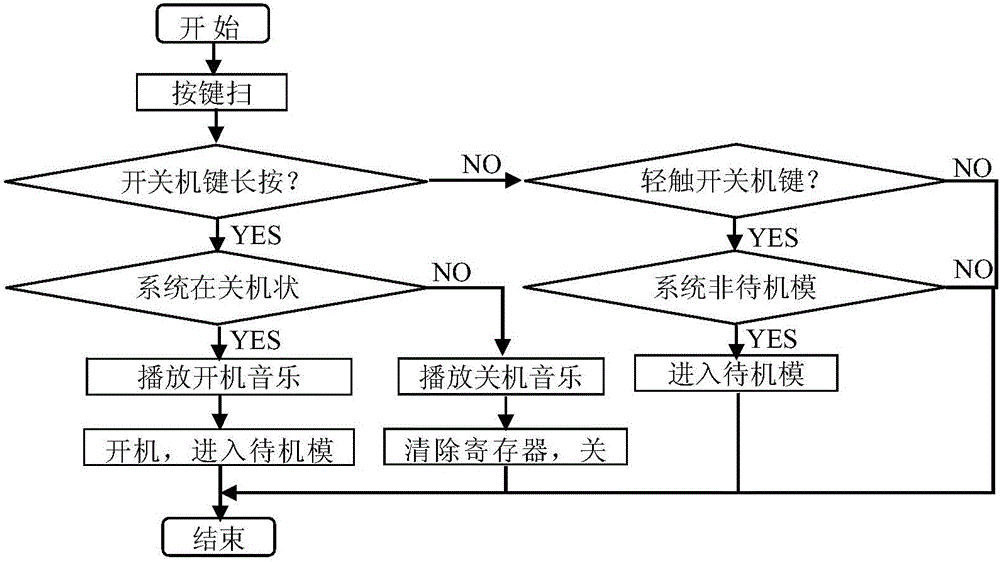

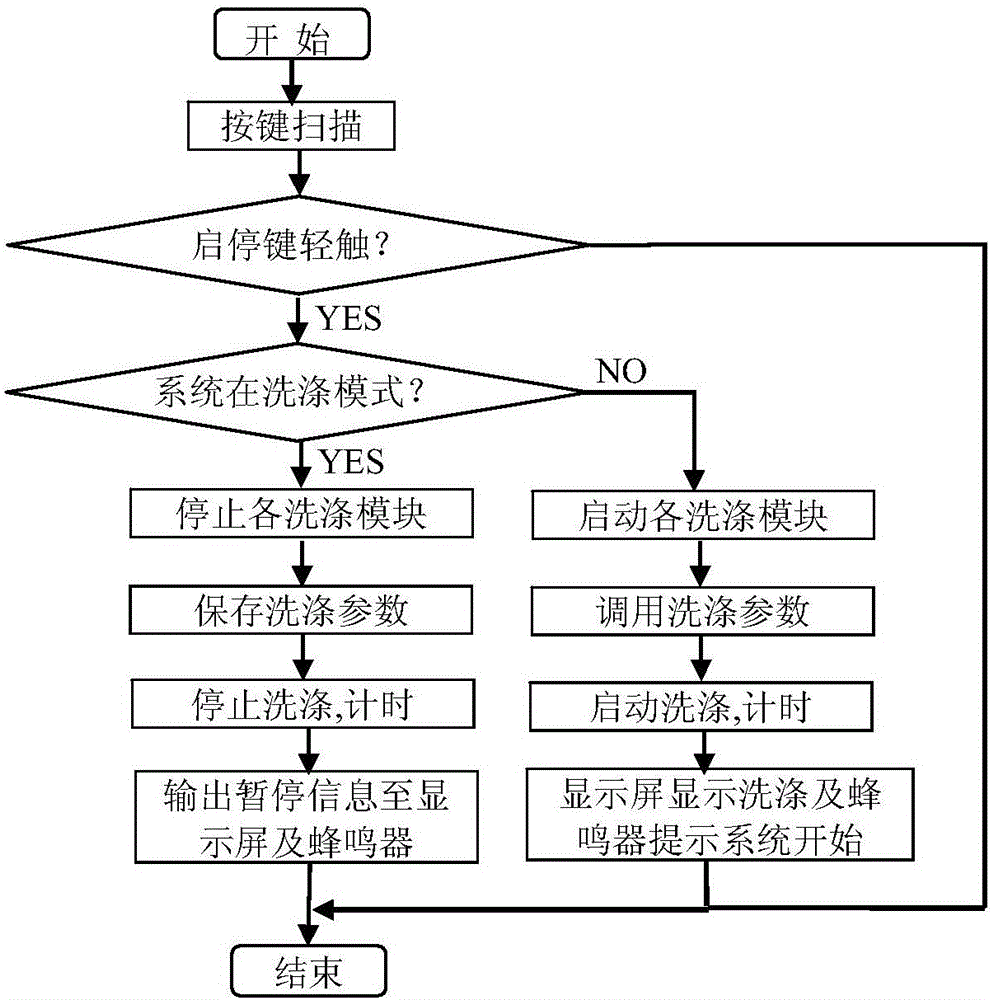

[0021] The digital display part 2 is used to display the remaining time of washing in various modes; the remaining time of each washing mode is displayed: in the mode selection stage, the time required for washing in the selected mode is displayed and flashes. Different washing modes and their different intensity and water level settings under the modes have different washing times. It stops flashing after entering the washing state, and counts down with the washing process, and the washing ends when the countdown reaches zero. Display fault code: During standby or washing, the system may have different faults, and when a fault occurs, the corresponding fault code will be dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com