Series-parallel hybrid stamping feeding-discharging manipulator

A manipulator and hybrid technology, applied in the field of manipulators, can solve the problems of poor load-carrying and adjustability, and achieve the effects of strong adjustability, efficient circulation and large working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

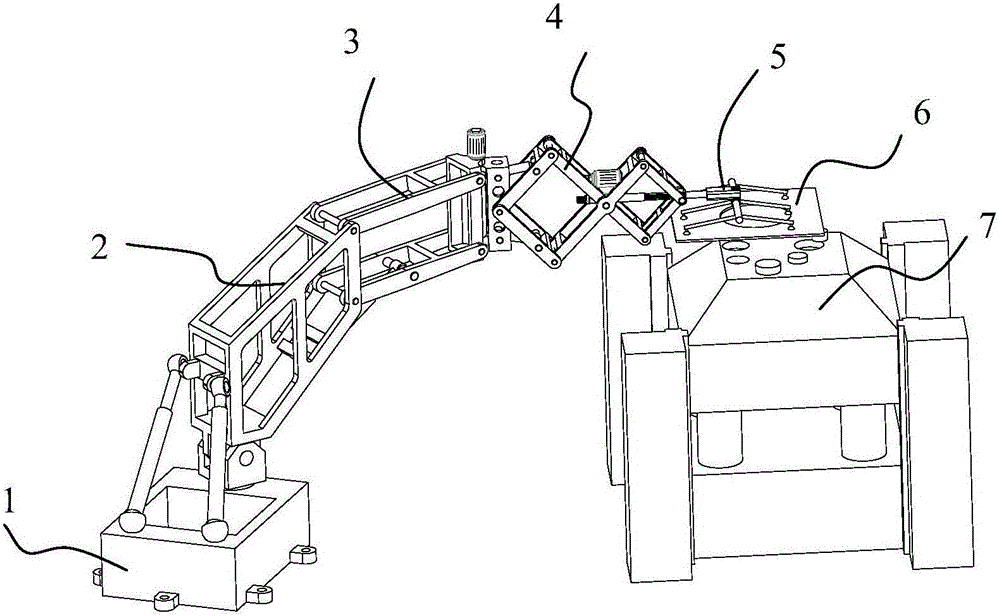

[0014] exist figure 1 In the schematic diagram of the serial-parallel hybrid stamping loading and unloading manipulator shown, the base 1 is connected to the main arm 2, the main arm is connected to the middle arm 3, the middle arm is connected to the small arm 4, the small arm is connected to the end picker 5, and the end picker The tool grabs the workpiece 6 and sends it to the press 7.

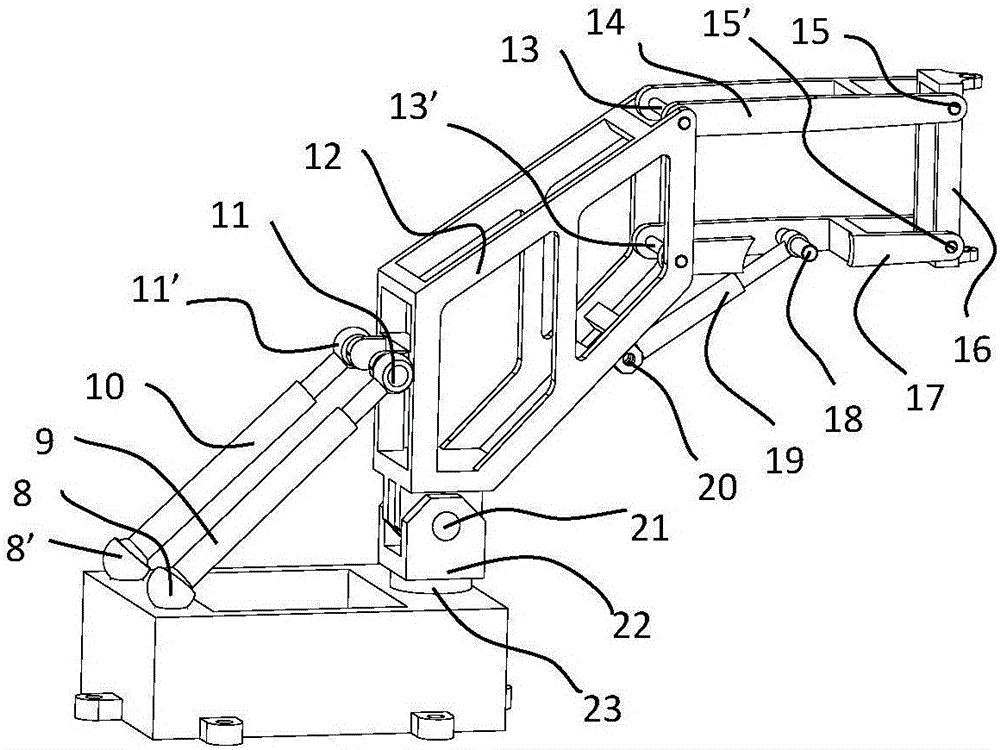

[0015] Such as figure 2 As shown, one end of the boom main part 12 in the boom is connected to one end of the first telescopic rod 9 and the second telescopic rod 10 through a pair of second ball pairs 11, 11', the first and second telescopic rods The rods are respectively connected to one side of the base through the first ball pair 8, 8'; the bottom of the U-shaped piece 22 is rotationally connected to the other side of the base through the sixth rotating shaft 23, and the upper end of the U-shaped piece is connected through the fifth rotating shaft 21 is connected with the main part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com