The Improved Process of Belt Pulley Casting and Its Pouring System

A pouring system and pulley technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems affecting the internal quality of castings and process yield, cumbersome processing operations, increasing the amount of molten iron, etc., to achieve the stability of the casting process , high process yield, and the effect of reducing turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Product Name Elevator Ditch Wheel, Material Ductile Iron FCD550.

[0021] In the improved process of belt pulley casting, molten iron enters from the bottom of the cavity of the middle rib plate through the inner gate 5 during the pouring process.

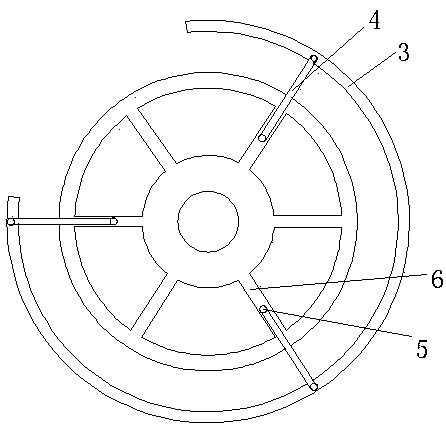

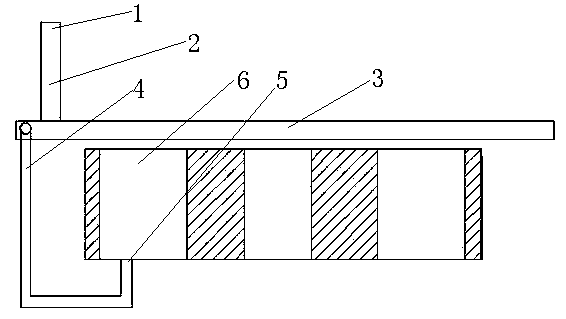

[0022] The gating system adopting the above-mentioned improved process includes a sprue 1, a sprue 2, an arc-shaped sprue 3 and several sub-runners 4; one end of the sprue 2 is connected to the sprue 1, and the other end of the sprue 2 is connected to The upper part of the arc-shaped runner 3 and the lower part of the arc-shaped runner 3 are connected to one end of a plurality of sub-runners 4, and the other ends of the plurality of sub-runners 4 are connected to the cavity 6 of the middle rib.

[0023] Three runners 4 are provided, and the runners are L-shaped.

[0024] The other ends of the several runners 4 are connected to the bottom of the cavity 6 of the middle rib.

[0025] In the existing pulley casting process, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com