Operating method of intelligent horizontal joint locking mechanism

A technology of horizontal joints and locking mechanisms, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult and accurate alignment of workpieces, tedious height adjustment, large gaps, etc., and achieve convenient, fast and efficient height adjustment The effect of stable operation and elimination of backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

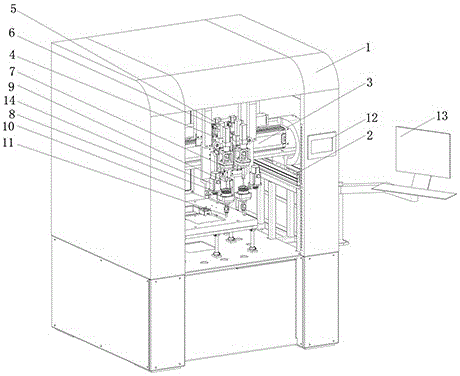

[0026] Such as figure 1 As shown, the working method of an intelligent horizontal joint locking mechanism in this embodiment, the specific working steps are as follows:

[0027] (1), first turn on the power supply, the staff set the overall operating parameters of the mechanism through the touch screen 12 and the controller 13, and then the X-axis manipulator 2, the Y-axis manipulator 3 and the Z-axis manipulator in the body 1 are automatically controlled by the PLC control program. precise positioning;

[0028] (2) Driven by the first electric cylinder 4, the Z-axis manipulator moves down to the target screw position, and the slot in the quick-change sleeve 11 springs into the bottom of the slot of the screw;

[0029] (3) Under the drive of the second electric cylinder 6, move upwards for a certain distance one by one, and then under the drive of the locking motor 5, follow the rotation speed of the screw 9 to unscrew the nut completely;

[0030] (4), the first brake 7 adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com