Semi-automatic assembly device for automobile cross shaft universal joint

A cross-axis universal and assembly device technology, which is used in assembly machines, vehicle parts, transportation and packaging, etc., can solve the problems of poor assembly quality stability, high labor intensity, and complex assembly procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

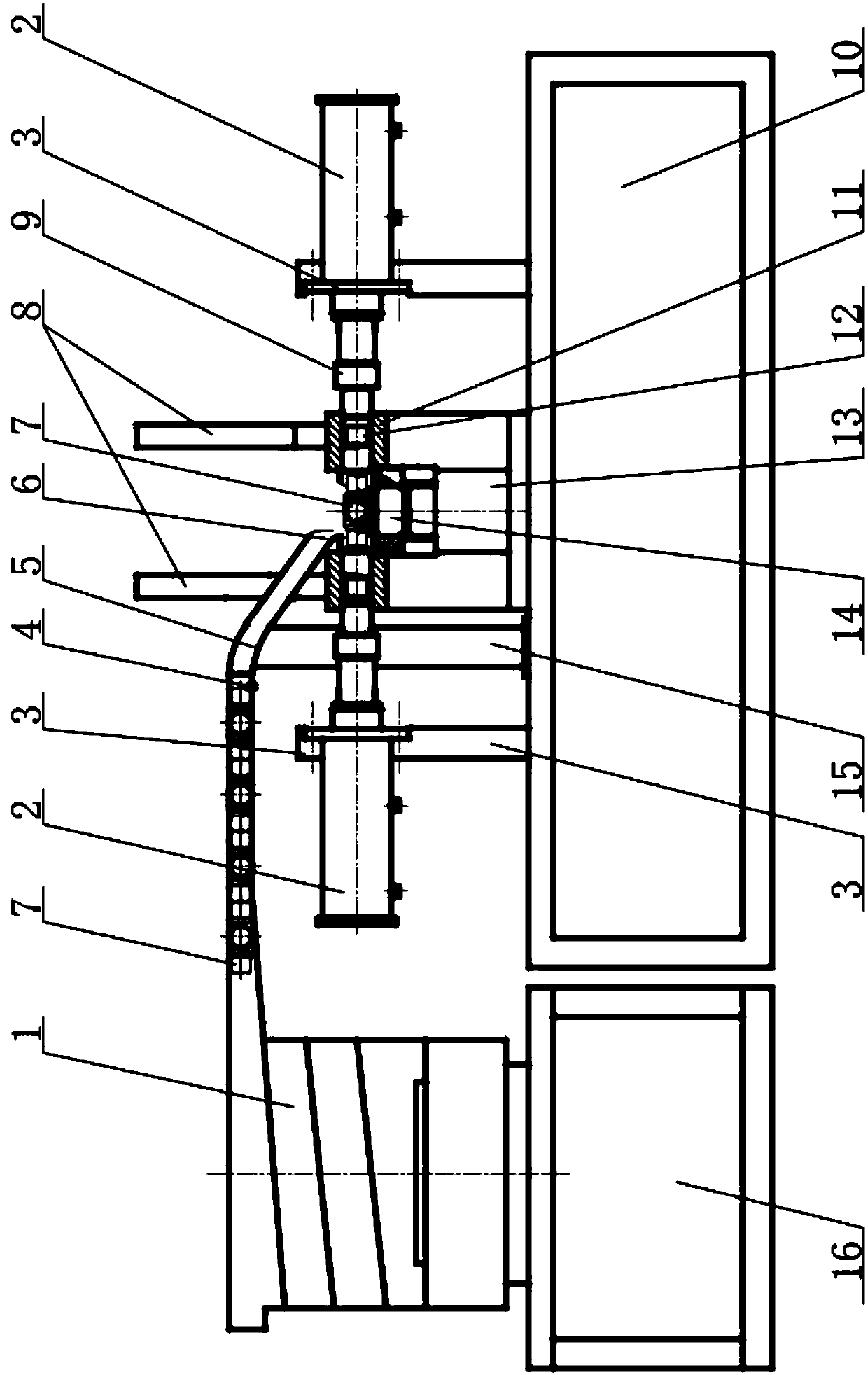

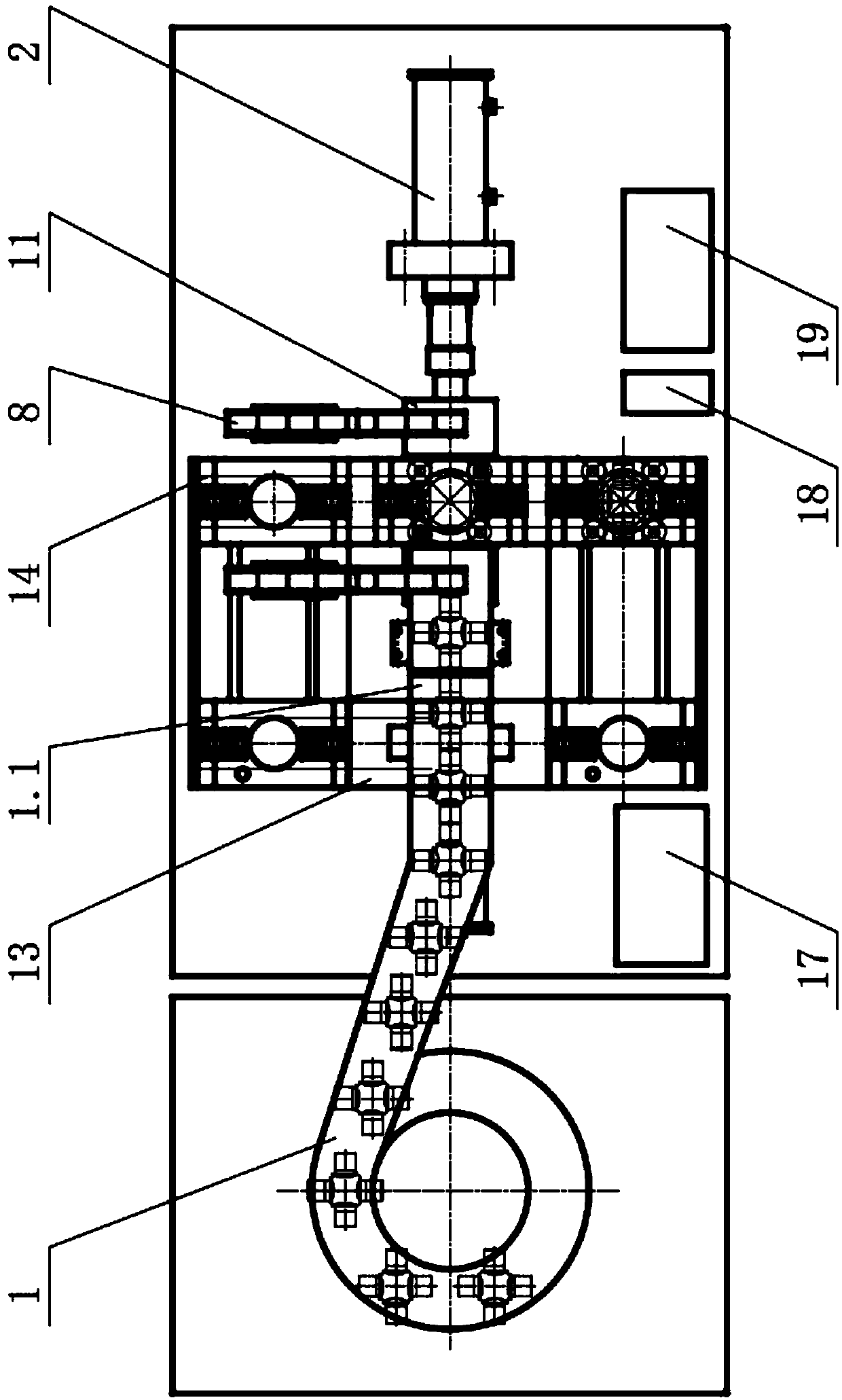

[0025] Semi-automatic assembly device for automobile cross shaft universal joint, such as Figure 1-Figure 6 As shown, it includes mechanical stand 10, cross shaft feeder support 16, cross shaft feeder support 16 is arranged side by side with mechanical stand 10, cross shaft feeder 16 support is provided with cross shaft feeder 1, mechanical The platform 10 is provided with a shaft sleeve feeding machine 8, a workpiece conveying device 13, and a shaft sleeve pressing station 13.4. side.

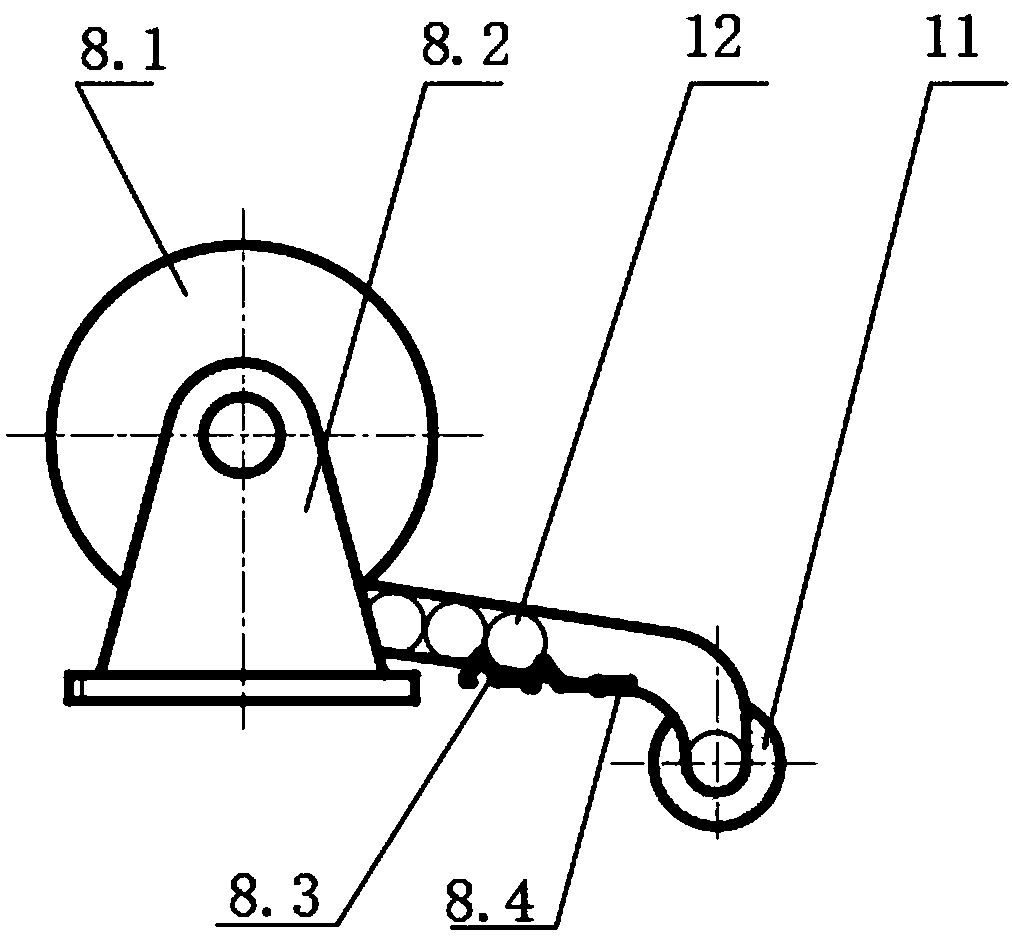

[0026] The cross-axis feeder 1 is provided with a high-frequency vibrator and a discharge port 1.1, the cross-axis feed stopper 4 is provided at the discharge port 1.1 of the cross-axis feeder 1, and a cross-axis feed stopper 4 is provided on the mechanical stand 10. Shaft feeding slide rail mounting bracket 15, cross shaft feeding slide rail mounting bracket 15 is equipped with cross shaft feeding slide rail 5, the feed port of cross shaft feeding slide rail 5 and the discharge port of cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com