A kind of assembly equipment of superconducting wire through pipe method

A technology for assembling equipment and superconducting wires, which is applied to the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems that the assembly process of the pipe-through method can only be assembled manually, and achieve overcoming efficiency Low, improve efficiency, enhance the effect of industrialization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

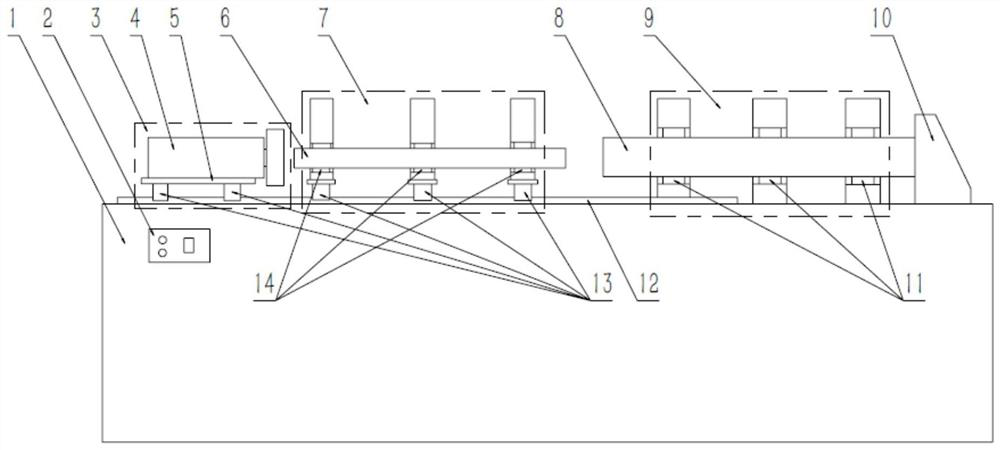

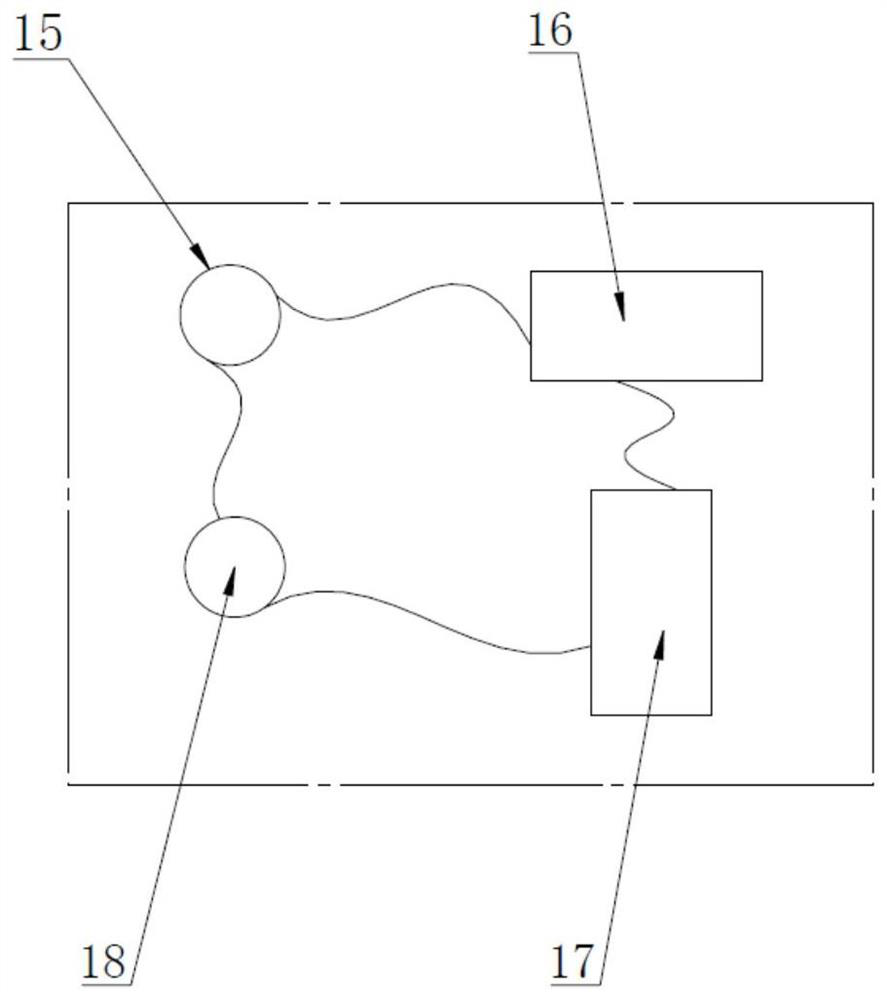

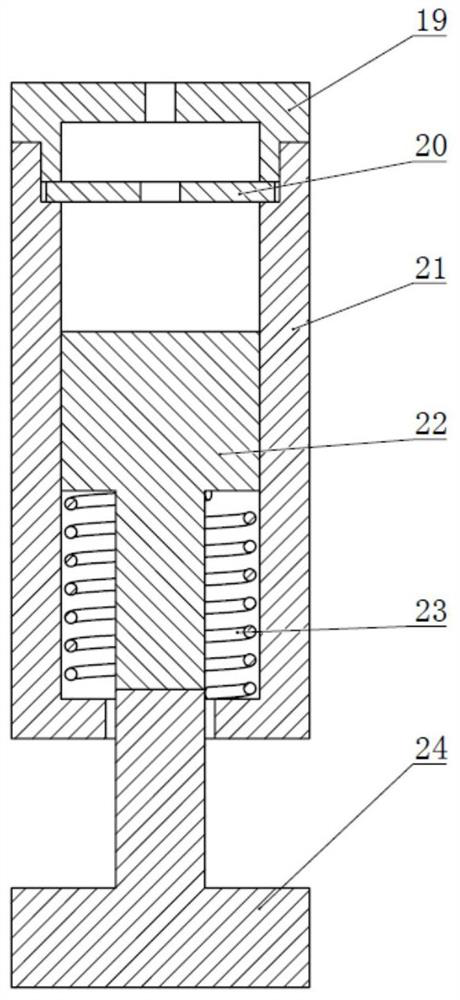

[0021] Embodiment 1: as Figure 1-5 As shown, a superconducting wire pipe-threading assembly device of the present invention includes a frame 1 and a control system 2, and the frame 1 is sequentially provided with an assembly mechanism 3, a hexagonal rod bundle clamping mechanism 7, and a copper tube clamping mechanism 9 and the copper pipe plug 10, the copper pipe clamping mechanism 9 is connected with the copper pipe plug 10 and fixed on the frame 1. Wherein the hexagonal rod bundle clamping mechanism 7 comprises the slide block 13 at its bottom, the hexagonal rod bundle base 28 located on the slide block 13, the quick clamp 25 located on the hexagonal rod bundle base 28, the hexagonal rod bundle base 28 and The hexagonal rod bundle tooling 14 of a plurality of corresponding sizes applicable to the hexagonal rod bundle 6 of various sizes on the quick clamp 25 . Described copper tube clamping mechanism 9 comprises the copper tube base 31 that is fixed on the frame 1, is loca...

Embodiment 2

[0023] Embodiment 2: It is basically the same as Embodiment 1, except that the hexagonal rod bundle tooling 14 and the copper tube tooling 11 are detachably connected to the hexagonal rod bundle clamping mechanism 7 and the copper tube clamping mechanism 9 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com