Six-degree-of-freedom location posture adjusting device for automatic assembly of large parts

A technology for automatic assembly and large parts, applied in the direction of workpiece clamping devices, manipulators, program-controlled manipulators, etc., can solve problems affecting production quality and production efficiency, limited scope of application, low manual accuracy and efficiency, and achieve assembly efficiency High, large range of motion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

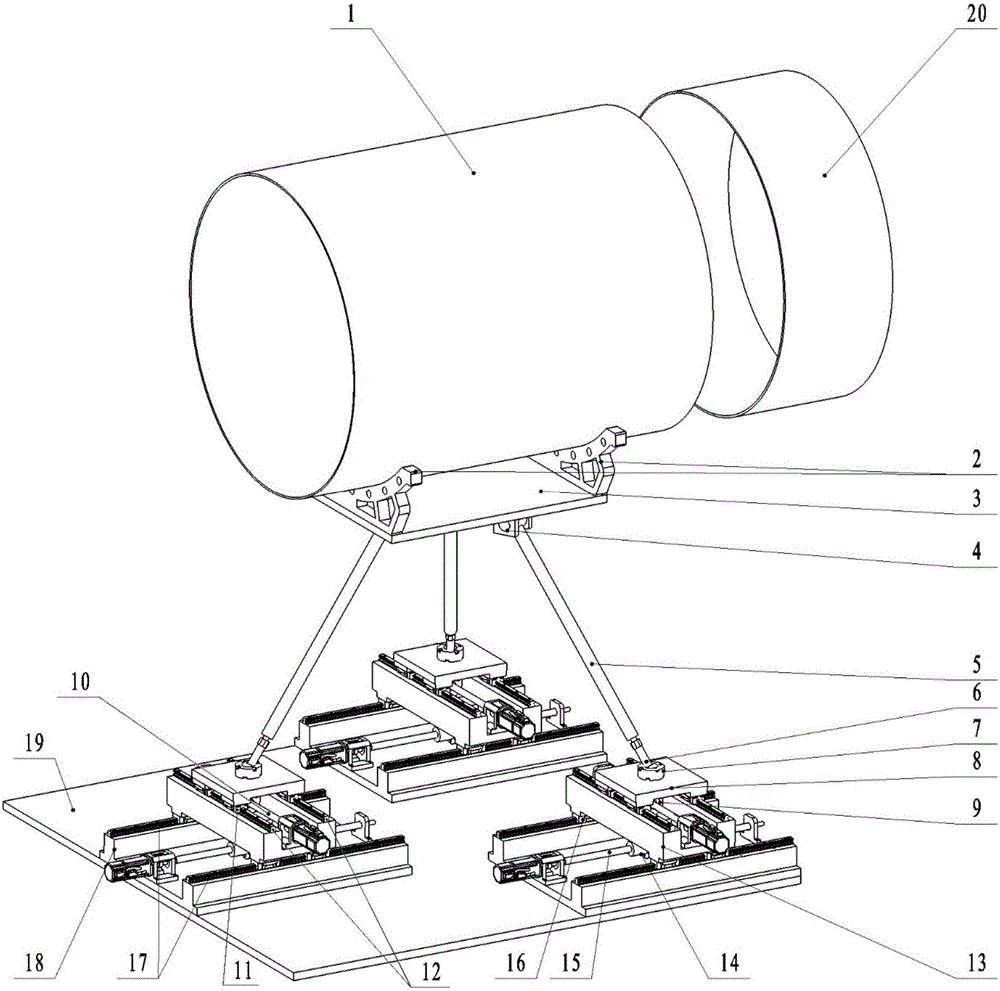

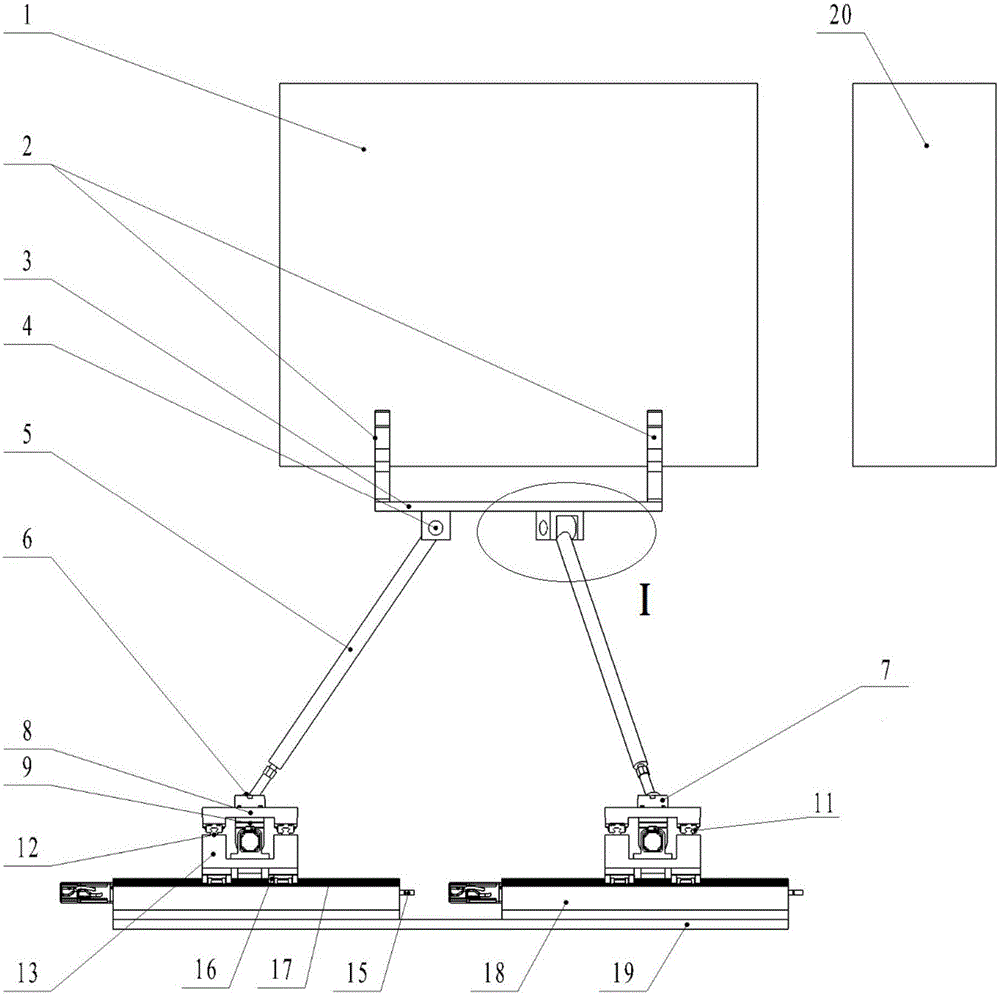

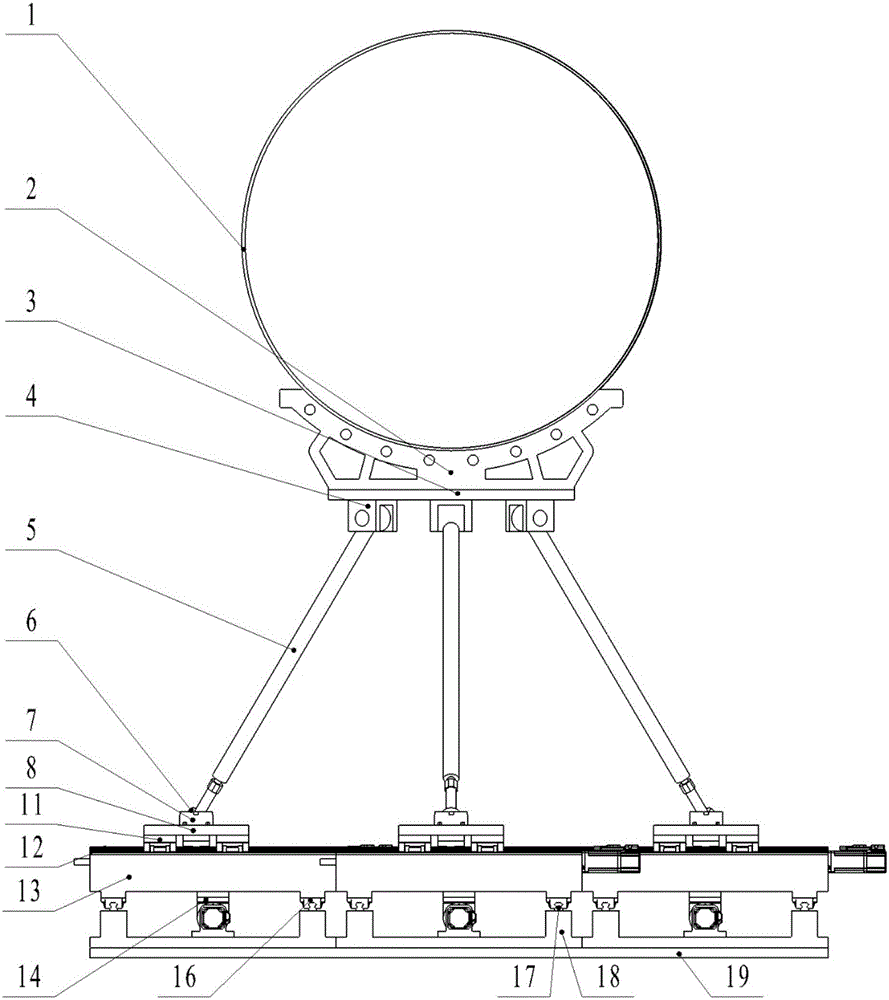

[0025] Such as figure 1 As shown, the present embodiment includes: an adjustment platform 3 with a large component bracket 2, a base 19 and three PPSR branch chains connected thereto respectively, wherein: the large component 1 to be adjusted and the large component bracket 2. Through arc-shaped surface contact connection, the large component bracket 2 is aligned and placed on the adjustment and movement platform 3 and fixedly connected with the adjustment and movement platform 3.

[0026] The adjusting and moving platform 3 adopts a flattened steel plate, which is used to support the large component bracket 2 and the large component 1 to be adjusted.

[0027] In this embodiment, the layout of the three PPSR branches is as follows Figure 1 to Figure 3 As shown, the three PPSR branched chain structures are exactly the same.

[0028] Such as Figure 4 As shown, the PPSR branch chain includes: a first moving pair, a second moving pair, a rotating pair 4, a support rod 5, a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com