Plate clamp special for power transformation operation and maintenance

A technology of operation and maintenance and board clamping, which is applied to folders, writing pads, printing, etc., can solve the problems of inconvenient writing, no function, and inconvenient operation, and achieve the effects of improving work efficiency, convenient carrying, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

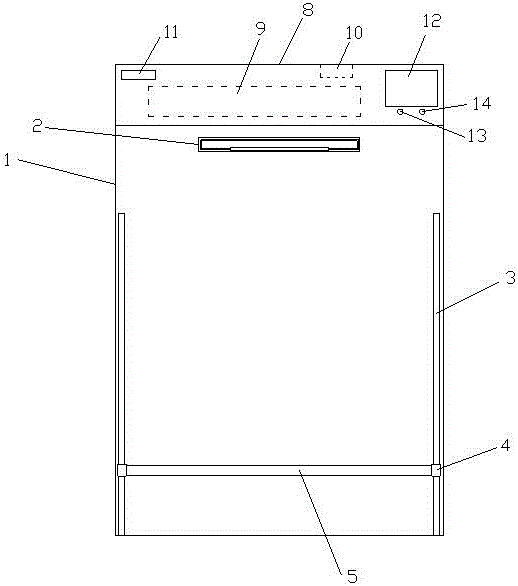

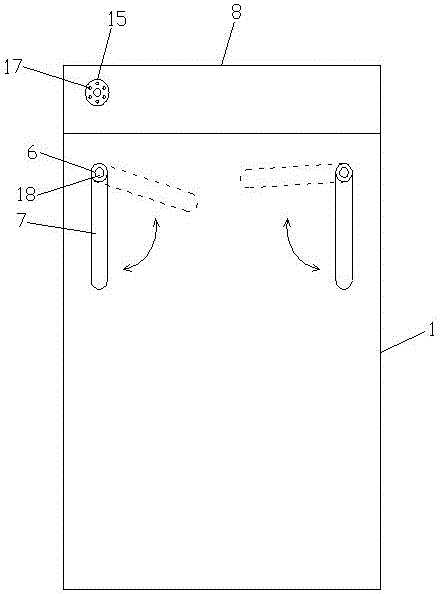

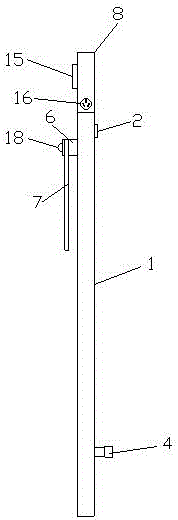

[0015] Such as Figure 1-3 The special plate clamp for power transformation operation and maintenance shown includes a bottom plate 1, a clamping portion 2 is provided on the front upper end of the bottom plate 1, and chute 3 is longitudinally provided on the left and right sides of the front of the bottom plate 1, and the slide The groove 3 is provided with sliders 4, and the sliders 4 are connected by bar-shaped barriers 5. The left and right sides of the reverse side of the bottom plate 1 are provided with a turntable 6, and the turntable 6 is provided with a clamping bar 7. The top of the bottom plate 1 is provided with a control device 8, the interior of the control device 8 is provided with a storage battery 9 and a memory card 10, a time display screen 11 is provided at the upper left corner of the front, and a liquid crystal display screen 12 is provided at the upper right corner. The bottom of the screen 12 is provided with a power switch 13 and a camera switch 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com