Plasma bag cleaning and breaking conveyor

A plasma bag and conveyor technology, which is applied in the field of plasma bag cleaning and broken bag conveyor, can solve the problems of low efficiency and high labor intensity of workers, and achieve the effects of preventing cross-contamination, realizing pollution recovery, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

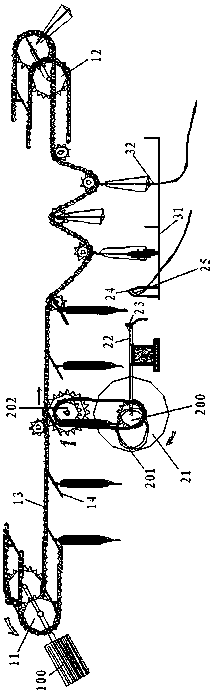

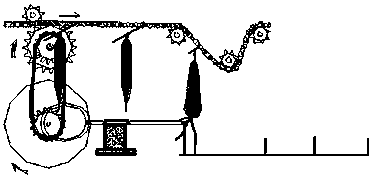

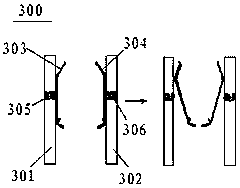

[0020] In a preferred embodiment, see Figure 1 to Figure 4 , Plasma bag cleaning and broken bag conveyor, including conveying mechanism, bag breaking mechanism and cleaning mechanism, etc.

[0021] The transmission mechanism includes a driving sprocket 11, a driven sprocket 12, a conveying chain 13, several limit gears and a plurality of connecting rods 14. The driving sprocket 11 and the driven sprocket 12 are respectively arranged at two ends, and the driving sprocket 11 and the driven sprocket 12 are wound with a conveying chain 13, the conveying chain 13 is provided with connecting rods 14 (equally spaced between the connecting rods), the connecting rods 14 are provided with hooks 141, and the limit gear is arranged above the broken bag cleaning area , in order to bend the conveyor chain 13 into a W shape.

[0022] In the embodiment, there are five limit gears, which are respectively the first, second, third, fourth and fifth limit gears from front to back.

[0023] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com