Lifting device

A technology of lifting device and lifting bracket, applied in the direction of lifting device, lifting frame, etc., can solve the problems of laborious lifting and heavy weight, etc., and achieve the effect of reducing work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

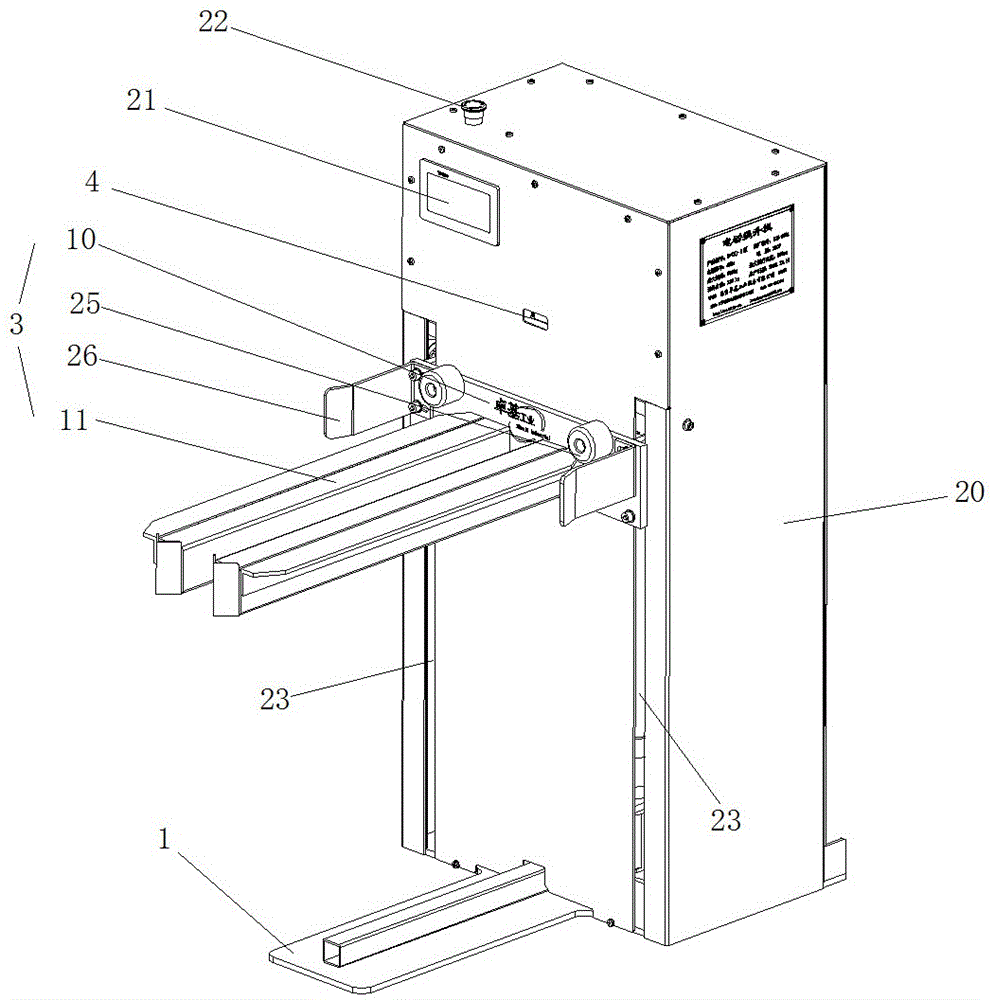

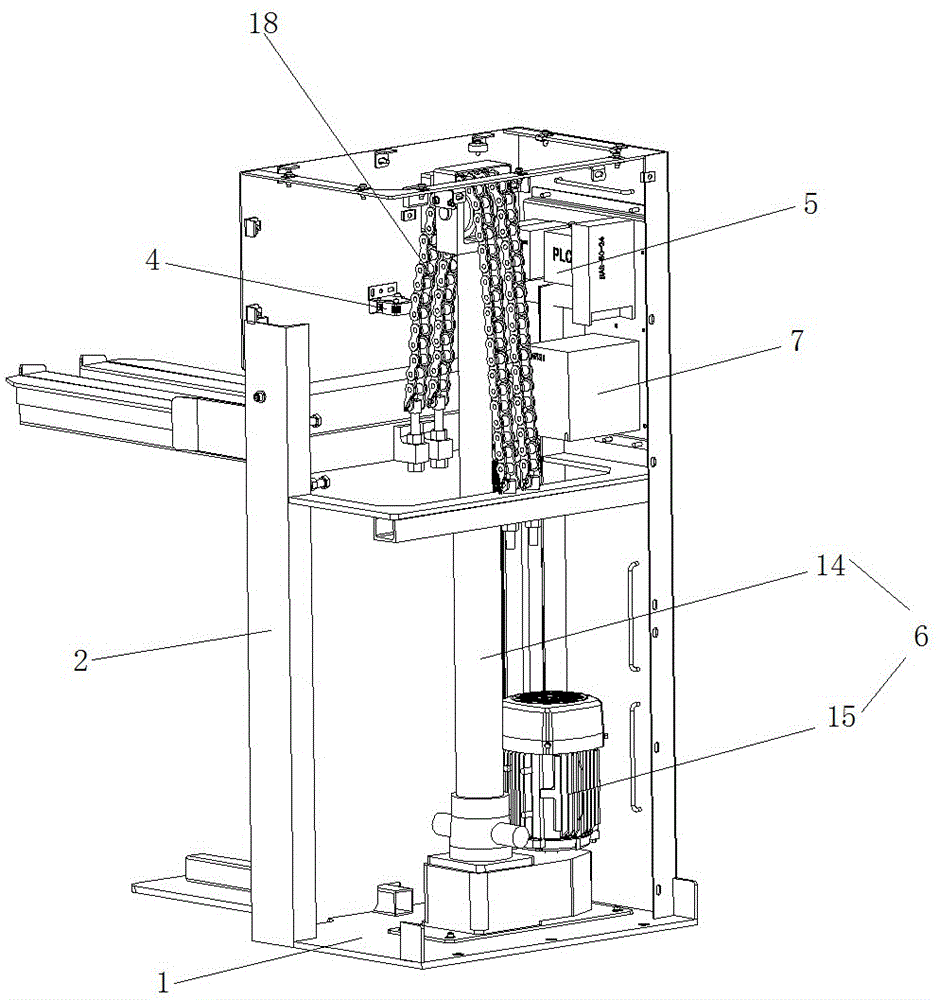

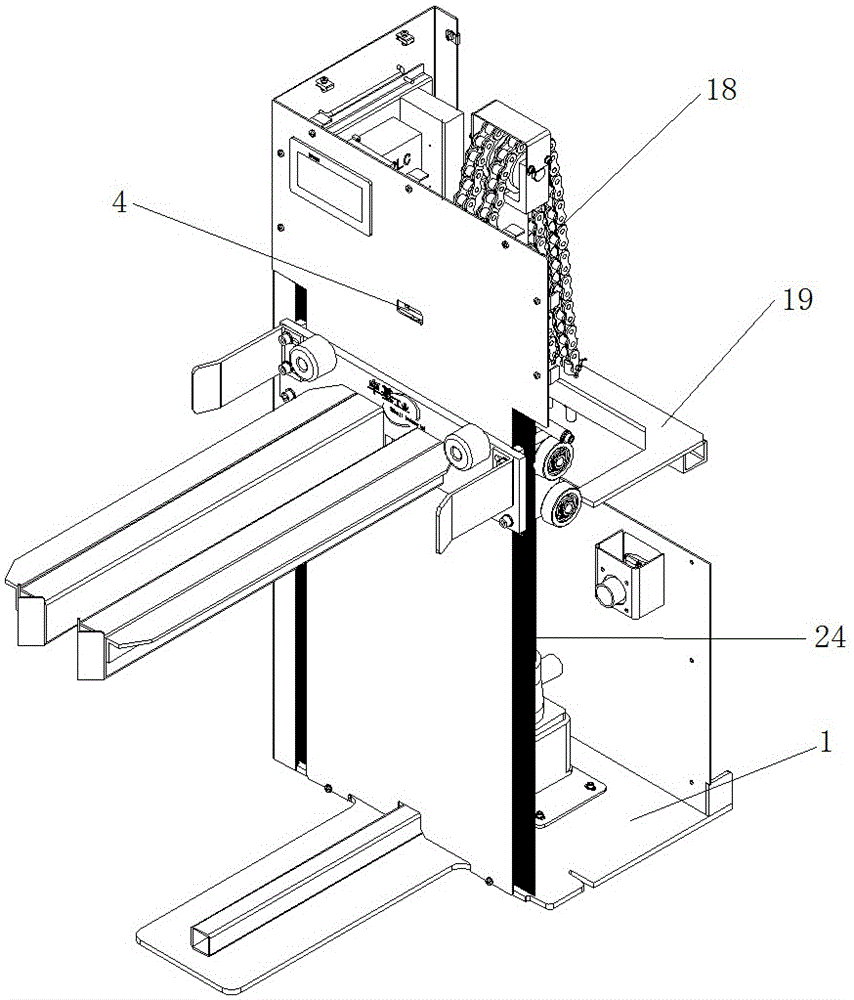

[0035] according to figure 1 , figure 2 , image 3 and Figure 4 As shown, the lifting device in the present invention includes: base 1, a pair of channel steel runways 2, telescopic cylinder assembly 6, lifting bracket assembly 3, optical sensor 4, main control single-chip microcomputer 5 and for optical sensor 4 , the main control microcontroller 5 and the power supply assembly 7 powered by the telescopic cylinder assembly 2.

[0036] Among them, such as Figure 8 and Figure 9 As shown, a pair of channel-steel runways 2 are respectively arranged on both sides of the front part of the base 1 with opposite openings.

[0037] Lifting bracket assembly 3 comprises bracket body and two groups of rollers 9 that are respectively connected to bracket body rear end both sides by roller fixing plate 8, can be as preferably: as Figure 5 and Figure 6 As shown, the bracket body is composed of a bracket fixing plate 10, a pair of bracket fork arms 11 horizontally connected on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com