Intelligent loading and unloading vehicle for small warehouse

A technology for loading and unloading trucks and warehouses, applied in the direction of lifting devices, etc., can solve the problems of inability to ensure accurate picking and placing of parts, large space occupied by shelves, waste of available space, etc., to shorten operating time, flexibly rotate, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

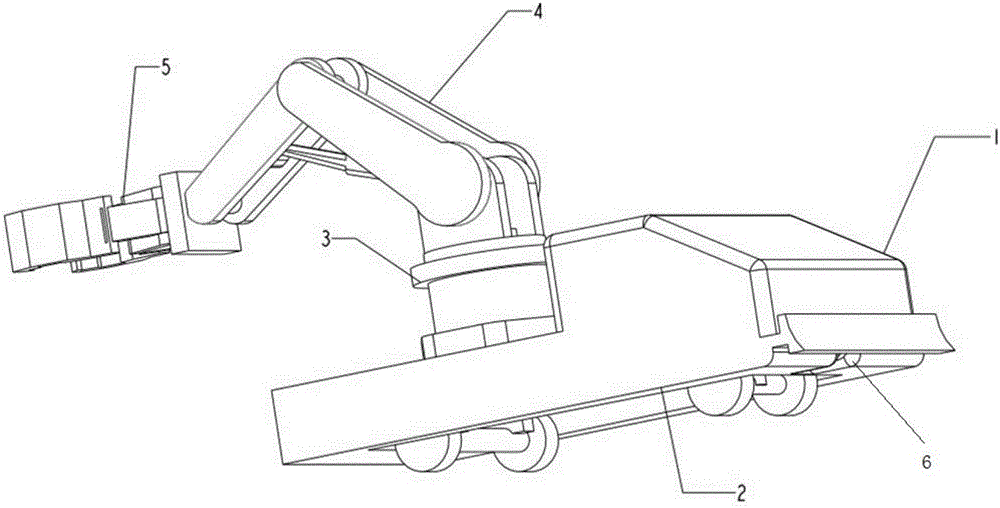

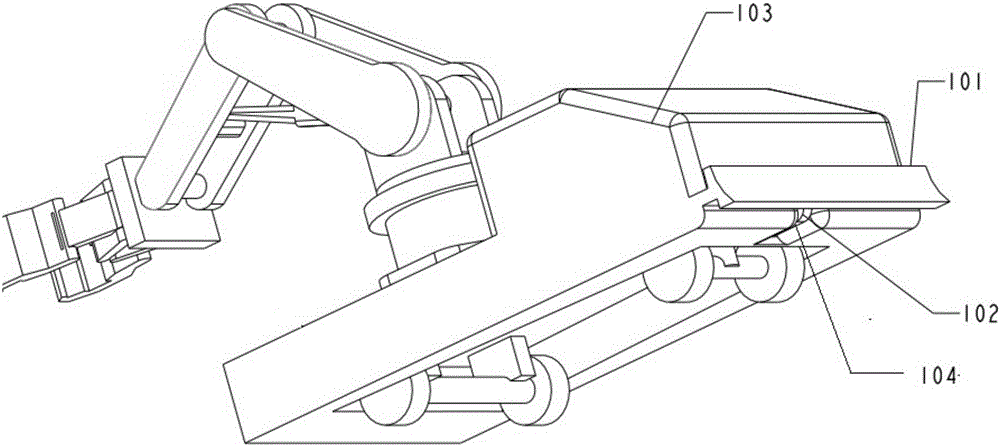

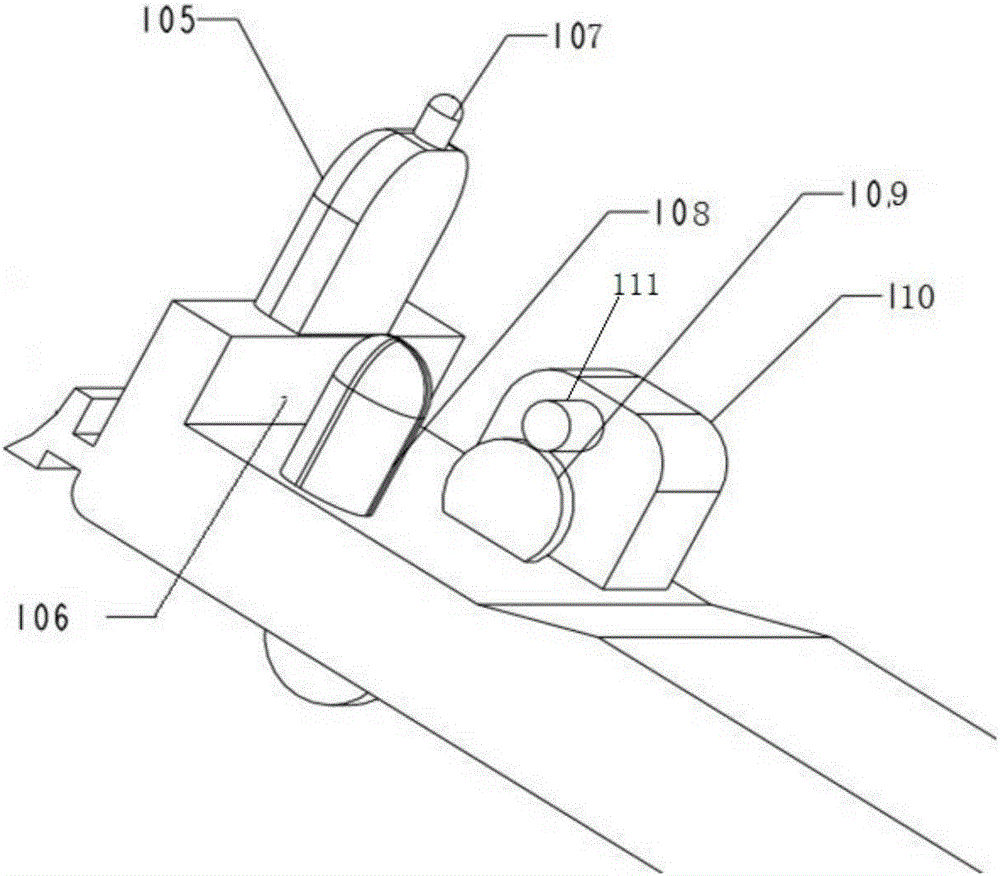

[0020] Specific implementation mode one: combine Figure 1-5 As shown, a small warehouse intelligent loading and unloading truck includes a car body 1, a chassis 2, a turret 3, a mechanical arm 4, and a manipulator 5; the chassis 2 is connected to the bottom of the car body 1, and the turret 3 is fixed to the rear of the car body 1 by bolts. The lower end of the mechanical arm 4 is connected with the turret 3 through the rotating shaft 405; the upper end of the mechanical arm 5 is connected with the upper end of the mechanical arm through the rotating shaft; A groove 6 is provided, a photoelectric sensor 102 and a magnetic stripe identifier 104 are installed inside the groove 6, a mechanical anti-collision mechanism 101 is installed at the head of the car body, a motor 110 is installed on one side of the central axis of the carriage 103; a motor is installed on one side of the motor 110 The output shaft 111 and the motor output shaft 111 are facing the central axis of the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com