Demulsification water purifying agent for composite flooding production fluid and preparation method thereof

A technology of emulsion water purifier and surfactant, which is applied in chemical dehydration/demulsification, separation methods, mining wastewater treatment, etc., can solve the problem of large amount of scum in the sewage system, and achieve surface performance and permeability Excellent, less scum generation, strong flocculation and cohesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The demulsification water purifying agent used for composite flooding production fluid is composed of the following components in mass percentage: polyether block copolymer 45%, polyether polyol 40%, esterified end-capped polyether surfactant 15% %.

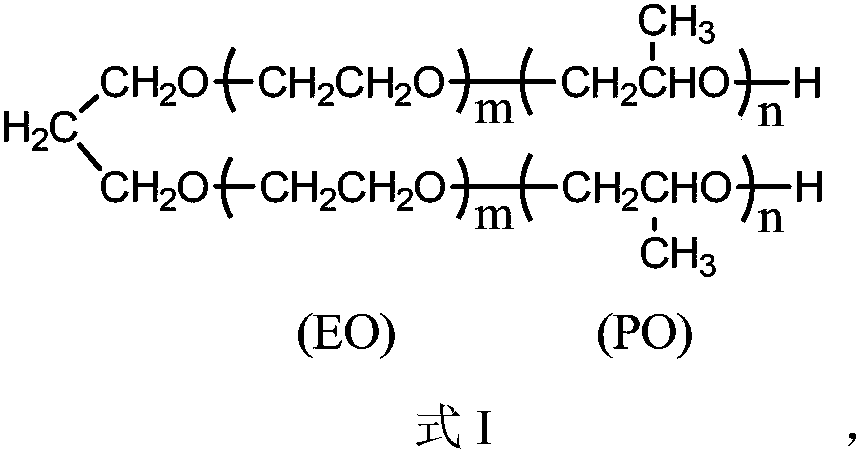

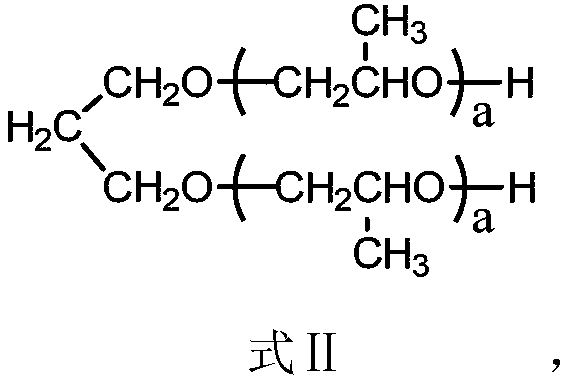

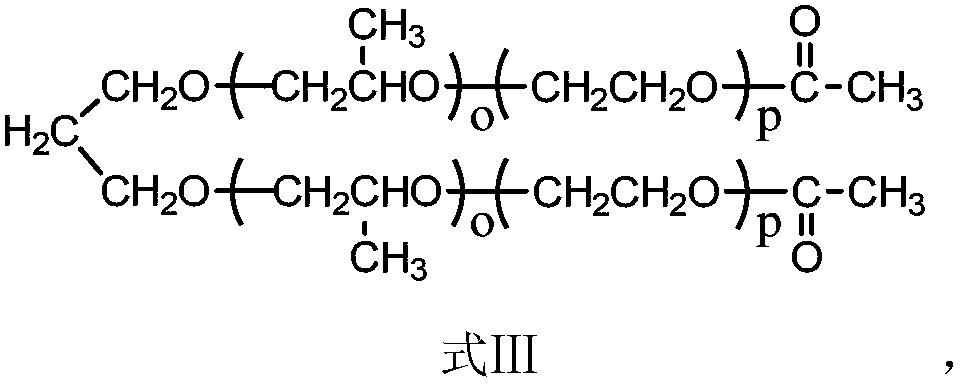

[0032] The polyether block copolymer is prepared by reacting the following raw materials in mass percentage: 2% of propylene glycol, 39.7% of propylene oxide, 58% of ethylene oxide, and 0.3% of potassium hydroxide. The preparation steps are: put the initiator propylene glycol in a pear-shaped flask, vacuum dehydrate at 95°C for 1 hour; add the catalyst KOH under nitrogen flow, heat at 120°C until the KOH is completely melted, vacuum dehydrate at 80°C for 1 hour, and introduce the dried high pressure while it is hot In the reaction kettle, cover it; replace and remove the air in the reaction kettle with nitrogen for 3 times, set the speed at 210 rpm, add the required EO monomer at 100°C, and carry out the polymerization rea...

Embodiment 2

[0037] The demulsification water purifying agent used for composite flooding production fluid is composed of the following components in mass percentage: polyether block copolymer 50%, polyether polyol 30%, esterified end-capped polyether surfactant 20% %.

[0038] The polyether block copolymer is prepared by reacting the following raw materials in mass percentage: 1% of propylene glycol, 66.9% of propylene oxide, 31.6% of ethylene oxide, and 0.5% of potassium hydroxide. The preparation steps are: put the initiator propylene glycol in a pear-shaped flask, vacuum dehydrate at 95°C for 1 hour; add the catalyst KOH under nitrogen flow, heat at 120°C until the KOH is completely melted, vacuum dehydrate at 80°C for 1 hour, and introduce the dried high pressure while it is hot In the reaction kettle, cover; fill nitrogen to replace and remove the air in the reaction kettle twice, set the speed at 180 rpm, add the required EO monomer at 100°C, and carry out the polymerization reactio...

Embodiment 3

[0043] The demulsification water purifying agent used for composite flooding production fluid is composed of the following components in mass percentage: polyether block copolymer 50%, polyether polyol 40%, esterified end-capped polyether surfactant 10% %.

[0044] The polyether block copolymer is prepared by reacting the following raw materials in mass percentage: 3.4% of propylene glycol, 30.7% of propylene oxide, 65.6% of ethylene oxide, and 0.3% of potassium hydroxide. The preparation steps are: put the initiator propylene glycol in a pear-shaped flask, vacuum dehydrate at 95°C for 1 hour; add the catalyst KOH under nitrogen flow, heat at 120°C until the KOH is completely melted, vacuum dehydrate at 80°C for 1 hour, and introduce the dried high pressure while it is hot In the reaction kettle, cover it; replace and remove the air in the reaction kettle twice with nitrogen, set the speed at 240 rpm, add the required EO monomer at 100°C, and carry out the polymerization react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com