A kind of anti-crack mountain tire tread rubber and preparation method thereof

A tread rubber and mountain technology, which is applied in the field of mountain tire tread rubber and its preparation, achieves the effects of good compatibility, improved wear resistance and increased elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

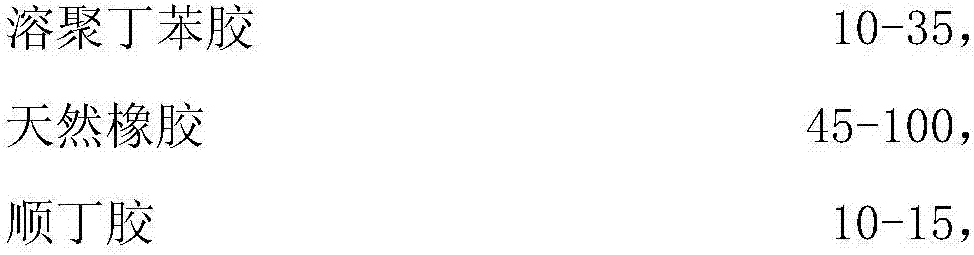

[0034] An anti-crack mountain tire tread rubber, comprising the following components in parts by weight:

[0035]

[0036]

[0037] Among them, the natural rubber is 20# standard natural rubber;

[0038] Sulfur content in sulfur ≥ 95wt%;

[0039] The anti-aging agent is N-phenyl-α-aniline and anti-aging agent 4020, and the weight ratio of the two is 1:2.

[0040] The tear-resistant resin is HR-801 aliphatic hydrocarbon resin.

[0041] The density of the tread rubber prepared in this embodiment is 1.090kg / dm 3 .

[0042] According to the proportioning of above-mentioned tread rubber, make following preparation:

[0043] a. master refining

[0044] a1. Take solution-polystyrene-butadiene rubber, natural rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent, protective wax, tear-resistant resin, white carbon black and silane coupling agent and add them to the internal mixer for mixing, Mixing for 1-2min;

[0045] a2. Add carbon black and softener, and ...

Embodiment 2

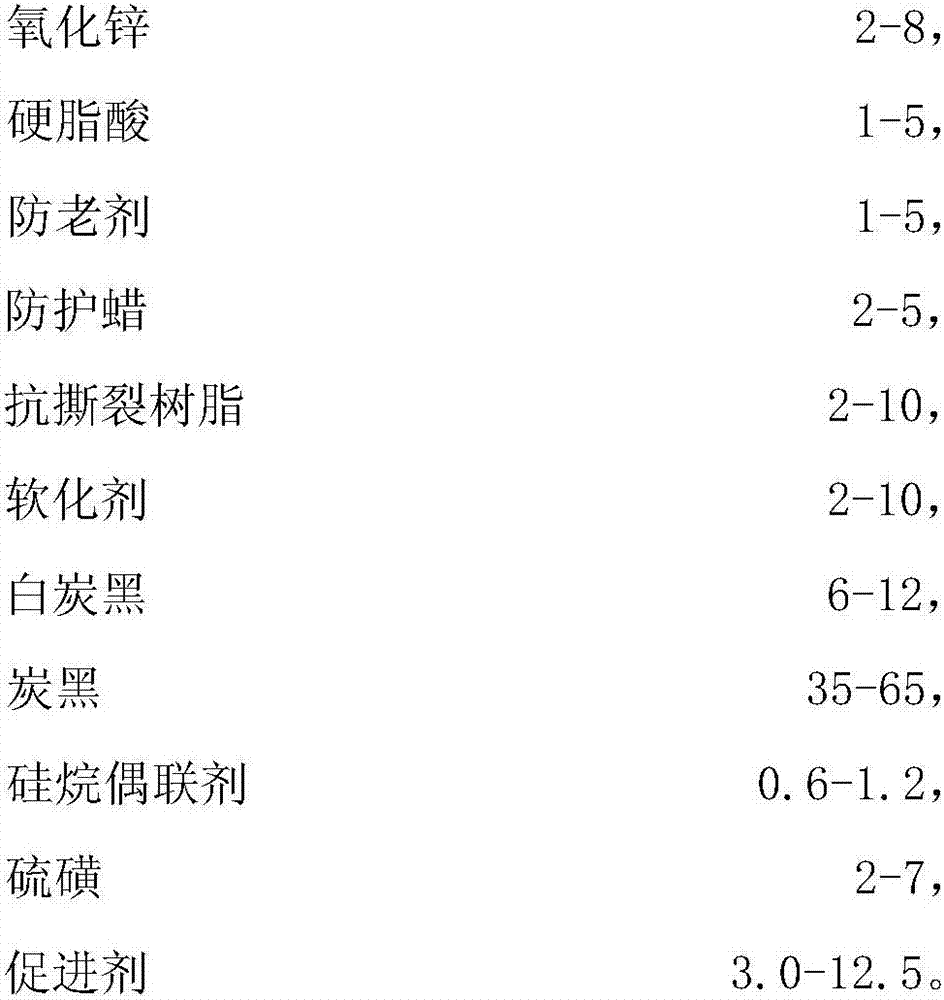

[0053] An anti-crack mountain tire tread rubber, comprising the following components in parts by weight:

[0054]

[0055] Among them, the natural rubber is 20# standard natural rubber;

[0056] Sulfur content in sulfur ≥ 95wt%;

[0057] Antiaging agent is N-phenyl-α-aniline.

[0058] The tear-resistant resin is AP-260, and its main body is hydrocarbon resin with functional groups.

[0059] The density of the tread rubber prepared in this embodiment is 1.093 / dm 3 .

[0060] According to the proportioning of above-mentioned tread rubber, make following preparation:

[0061] a. master refining

[0062] a1. Take solution-polystyrene-butadiene rubber, natural rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent, protective wax, tear-resistant resin, white carbon black and silane coupling agent and add them to the internal mixer for mixing, Mixing for 1-2min;

[0063] a2. Add carbon black and softener, and mix for 2-3 minutes;

[0064] a3. Tablet pressing...

Embodiment 3

[0071] An anti-crack mountain tire tread rubber, comprising the following components in parts by weight:

[0072]

[0073] Among them, the natural rubber is 20# standard natural rubber;

[0074] Sulfur content in sulfur ≥ 95wt%;

[0075] The anti-aging agent is N-phenyl-N'-isopropyl-p-phenylenediamine.

[0076] The tear-resistant resin is HR-801 aliphatic hydrocarbon resin and the main body of AP-260 is hydrocarbon resin with functional groups.

[0077] The density of the tread rubber prepared in this embodiment is 1.087kg / dm 3 .

[0078] According to the proportioning of above-mentioned tread rubber, make following preparation:

[0079] a. master refining

[0080] a1. Take solution polystyrene butadiene rubber, natural rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent, protective wax, tear-resistant resin, white carbon black and silane coupling agent and add them to the internal mixer for mixing, Mixing for 1-2min;

[0081] a2. Add carbon black an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap