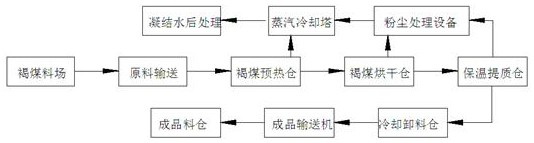

A lignite drying and upgrading system

A technology for upgrading and lignite, applied in solid fuel, petroleum industry, fuel and other directions, can solve the problems of large heat consumption of drum structure, difficult sealing, large workload, etc., and achieve environmental protection, constant working temperature, high temperature easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

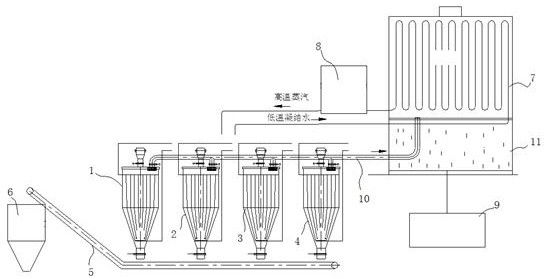

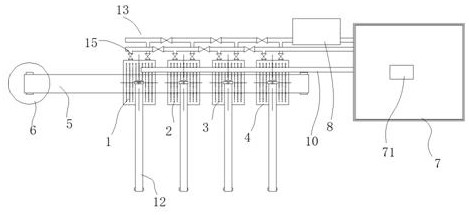

[0022] see Figure 1-3 As shown, a lignite drying and upgrading system includes:

[0023] Four silos with heat exchange function, namely silo 1, silo 2, silo 3, silo 4 and heat exchange device 7 that can provide heat exchange medium for heat exchange to the four silos; four The discharge port of the silo is provided with a finished product conveyor 5 for outputting the finished material to the finished product silo 6, and the feed port side of each silo is respectively provided with a feed conveyor 12; There are medium inlets and medium outlets respectively, and the medium inlets and medium outlets of the four silos are respectively connected to the medium flow direction switching control pipeline 13, which can be controlled by controlling the opening or closing of the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com