Downhole directional hole bedding guided drilling system and method based on formation lithology identification

A technology for formation lithology and directional drilling, which is applied in directional drilling, automatic control systems for drilling, drilling equipment, etc. It can solve the problems of unknown detailed fluctuations of the formation and the inability to ensure the long-distance extension of the actual drilling trajectory along the bed. Drilling construction efficiency and utilization effect, and the effect of ensuring the safety of drilling construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

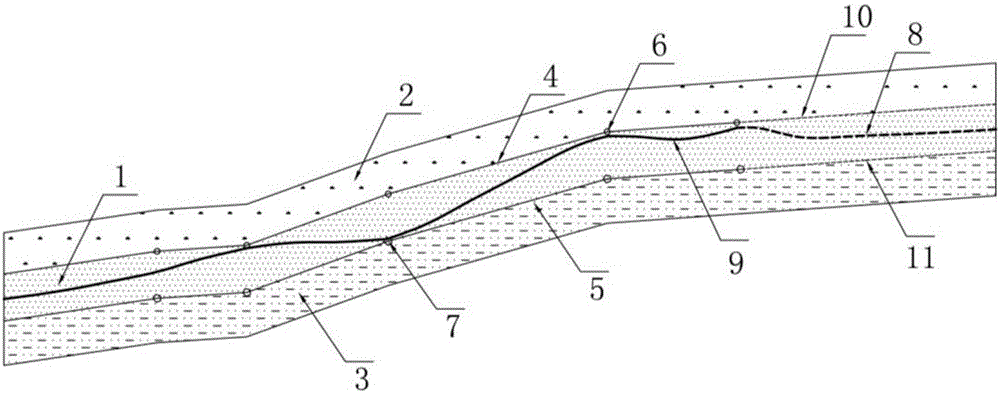

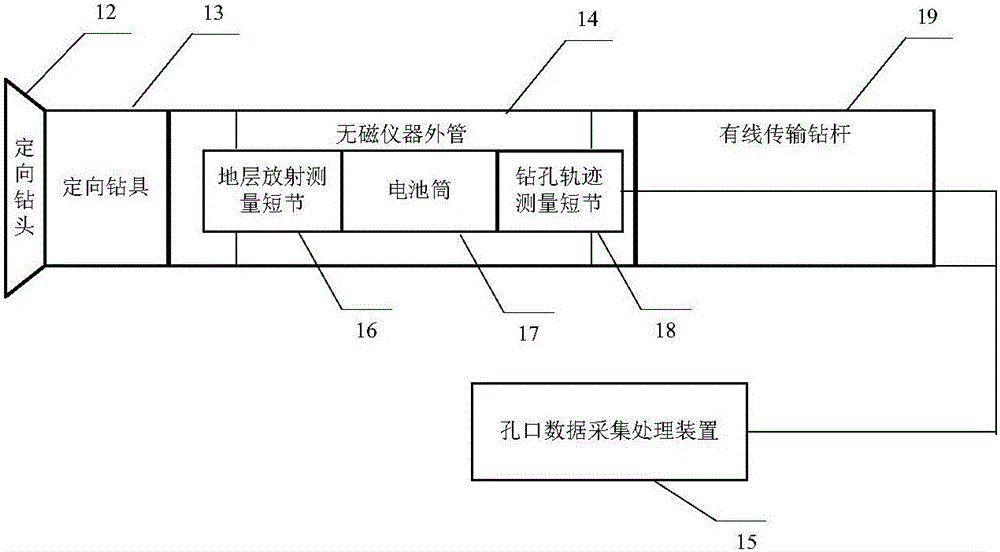

[0036] see figure 1 , based on coal-measure formation lithology identification while drilling, the downhole directional hole drilling method along the bedding, the working steps are as follows:

[0037]Step 1: Preliminary design of downhole directional hole trajectory. Firstly, according to the construction purpose of the downhole directional hole, select the appropriate complete coal formation as the drilling target formation 1; then, according to the target coverage area of the downhole directional hole, design the azimuth and the left and right displacement of the downhole directional hole, and determine the plane extension direction of the downhole directional hole; then according to the target The thickness and inclination of formation 1, calculate the elevation of the upper boundary line 4 and the lower boundary line 5 along the extension direction of the downhole directional hole plane, design the downhole directional hole inclination and up and down displacement, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com