Rolling piston used for refrigeration compressor

A technology of refrigeration compressors and rolling pistons, which is applied in the direction of machines/engines, rotary piston type/oscillating piston type pump components, mechanical equipment, etc., which can solve the problems of difficult processing, complex structure, high cost, etc., and facilitate mass production , The structure of the piston is simple and the processing cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

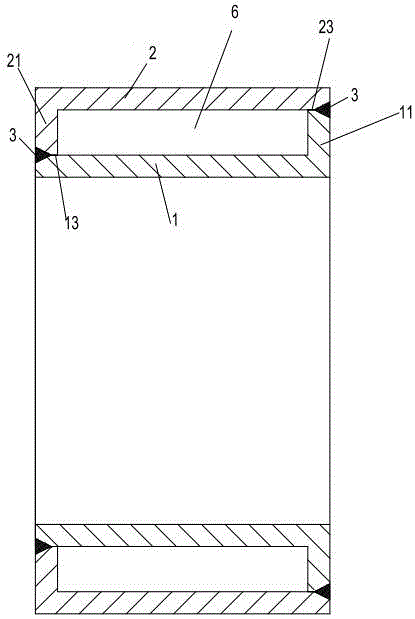

Embodiment 1

[0023] Example 1, such as figure 1 As shown, a rolling piston for a refrigeration compressor includes an inner tube 1 and an outer tube 2, one end of the inner tube is axially provided with an outward rib 11, one end of the outer tube is axially provided with an inward rib 21, the inner tube, A cavity 6 is formed between the outer tubes.

[0024] The inner pipe rib 11 is connected to the inner surface 23 of one end of the outer pipe by welding 3 , and the outer pipe rib 21 is connected to the outer surface 13 of the inner pipe by welding 3 .

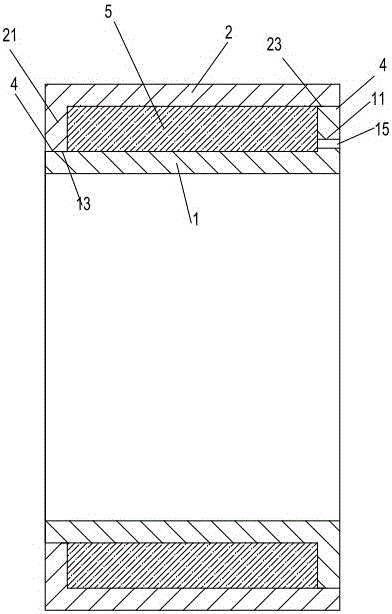

Embodiment 2

[0025] Example 2, such as figure 2 shown, as figure 1 As shown, a rolling piston for a refrigeration compressor includes an inner tube 1 and an outer tube 2, one end of the inner tube is axially provided with an outward rib 11, one end of the outer tube is axially provided with an inward rib 21, the inner tube, A cavity 6 is formed between the outer tubes.

[0026] The inner tube rib 11 is connected with the inner surface 23 of one end of the outer tube as an interference connection 4 , and the outer tube rib 21 is connected with the outer surface 13 of the inner tube with an interference connection 4 .

[0027] The cavity is filled with plastic 5 to increase the supporting force of the inner tube and the outer tube.

[0028] The above-mentioned filling plastic 5 can be injected into the cavity 6 through the through hole 15 arranged on the rib of the inner tube, or can be injected into the cavity through the through hole (not shown in the figure) arranged on the rib of the ...

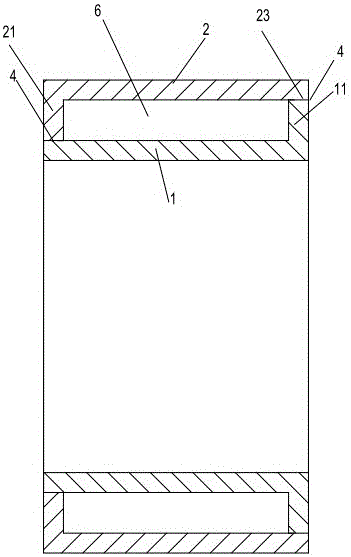

Embodiment 3

[0029] Example 3, such as image 3 As shown, the plastic 5 is not filled in the cavity 3, and the rest are the same as in the embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com