A kind of biomass raw material powder making device

A technology of biomass raw material and pulverizing device, which is applied in the direction of block/powder fuel preparation, fuel supply, combustion method, etc. The powder is fine and uniform, and the effect of reducing drying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

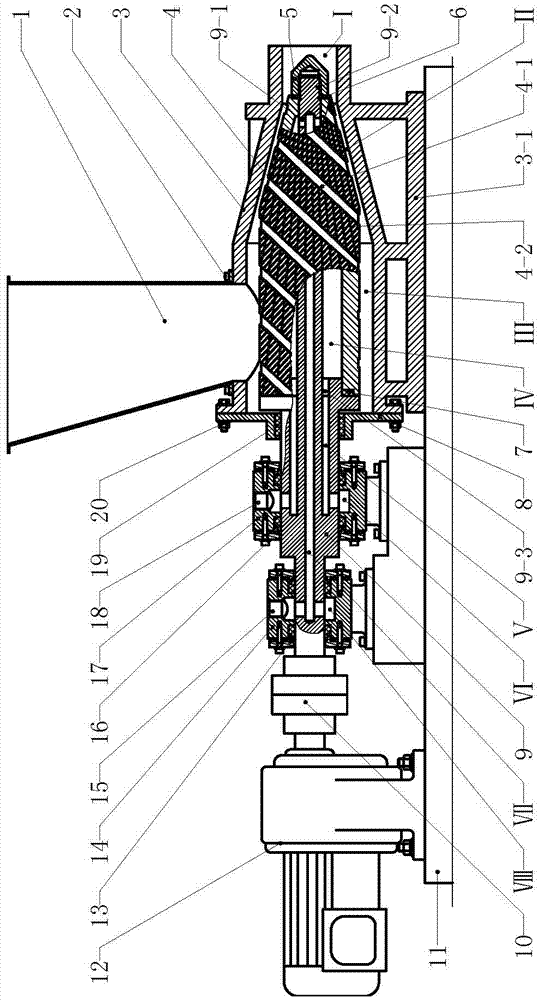

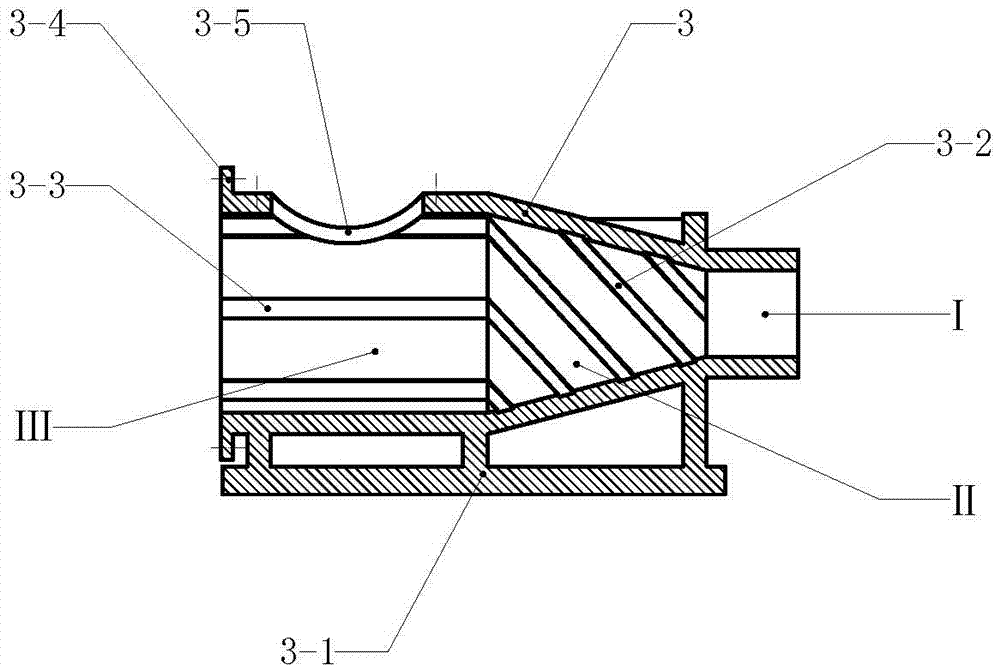

[0015] Example figure 1 with figure 2 In the illustrated embodiment, the biomass raw material milling device is mainly composed of a geared motor 12, a coupling 10, a support plate 8, a rotating shaft 9, a milling machine, a hopper 1 and a base 11, a geared motor 12 and a milling machine Installed on the machine base 11, the center of the support plate 8 has a sliding bearing 19, the middle shaft of the rotating shaft 9 is installed in the sliding bearing 19, and the output shaft of the geared motor 12 is connected to the rear end of the rotating shaft 9 through a coupling 10. There are water supply channel Ⅶ and return water channel Ⅴ in the shaft body of 9; on the rear shaft body of the rotating shaft 9, there are a water supply sleeve 14 and a return sleeve 17, and the water supply sleeve 14 has a water supply cavity Ⅷ, and the water supply cavity Ⅷ is connected To the water supply channel Ⅶ in the body of the rotating shaft 9, the water supply cavity Ⅷ is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com