A sawing machine for biomass crushing

A sawing machine and biomass technology, applied in the field of biomass fuel pretreatment equipment, can solve the problems of low crushing efficiency, increased production cost, and high requirements for drying biomass raw materials, and achieve high crushing efficiency and reduce drying requirements. , the effect of reducing drying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

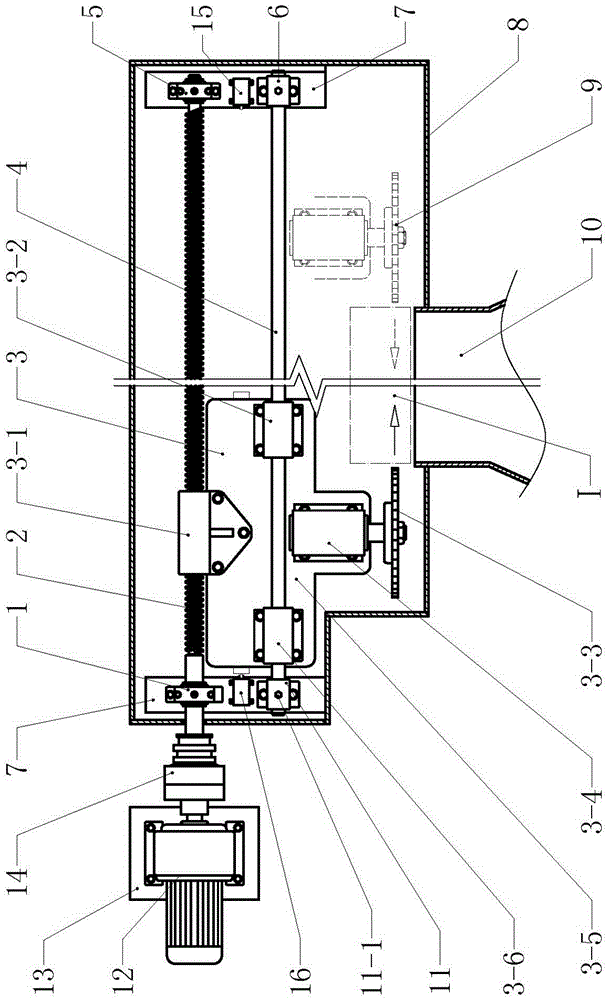

[0012] Example Attached figure 1 In the shown embodiment, the sawing machine used for biomass crushing is mainly composed of a geared motor 12, a clutch 14, a frame 7, a sawing assembly 3, a driving screw 2, a supporting connecting rod 4 and an enclosure wall 8, Frame 7 is arranged in enclosure wall body 8, and sawing assembly 3 is made up of mobile chassis 3-5, driving screw sleeve 3-1, sliding bearing, high-speed motor 3-4 and circular saw blade 3-3, and driving screw Cover 3-1, sliding bearing and high-speed motor 3-4 are installed on the mobile chassis 3-5, the axis of drive screw sleeve 3-1 and the axis of sliding bearing are parallel to each other, the axis of high-speed motor 3-4 rotating shaft and sliding bearing The axes are perpendicular to each other, and the circular saw blade 3-3 is installed on the rotating shaft of the high-speed motor 3-4; the driving screw 2 is arranged in the driving screw sleeve 3-1 of the sawing assembly 3, and the left and right ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com