Grouting structure and grouting method for large-diameter high-strength pressure pipelines

A high-strength pressure, large-diameter technology, used in infrastructure engineering, construction, etc., can solve the problems of complex welding process of steel lining sealing, unfavorable construction period, high requirements on ambient temperature and humidity, etc., to shorten the construction period and reduce drying requirements. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

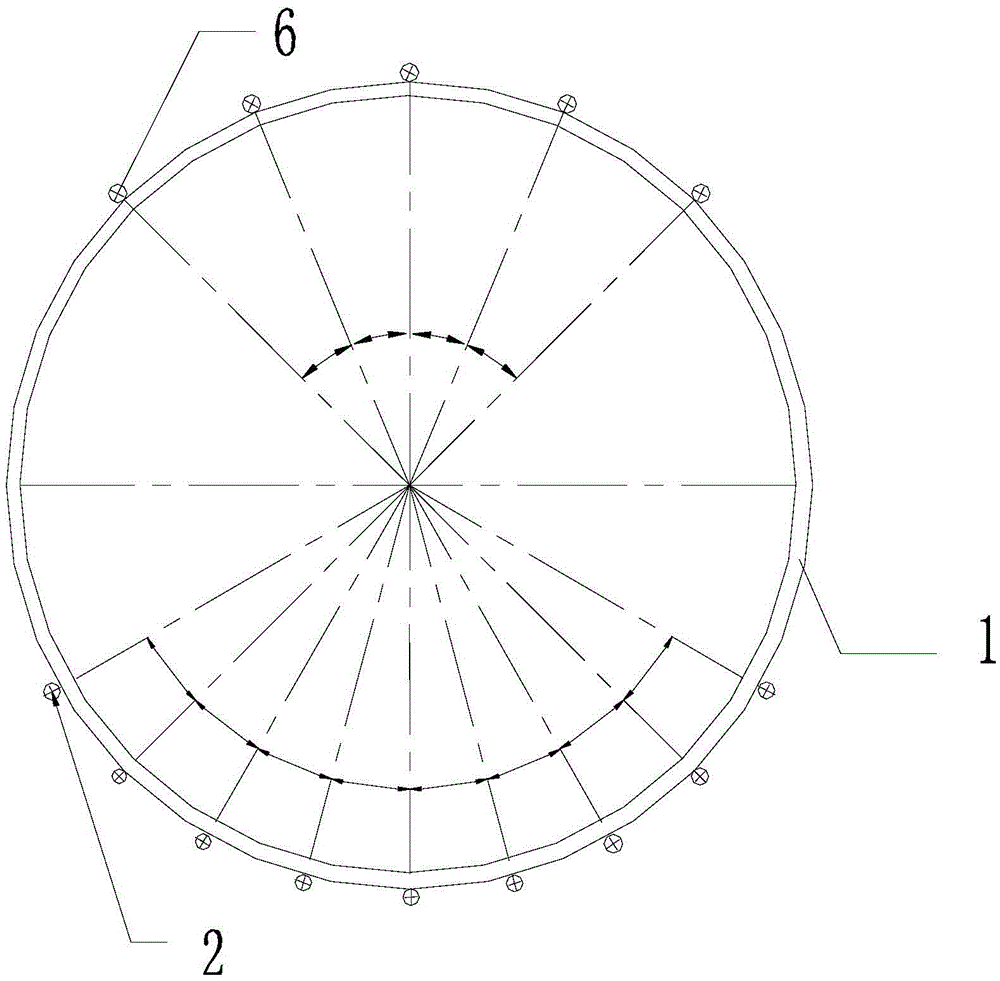

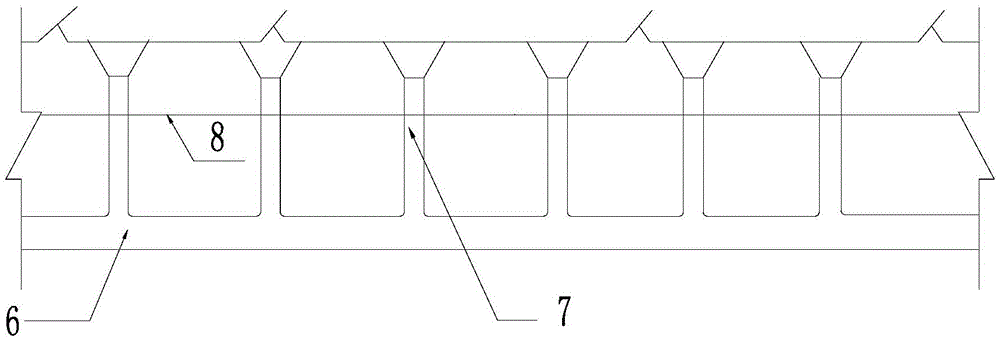

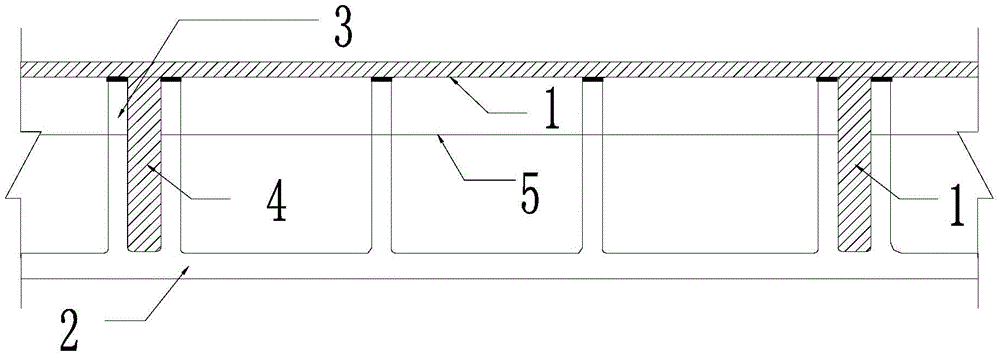

[0022] Such as figure 1 , figure 2 and image 3 As shown, in order to solve the above-mentioned technical problems, the large-diameter high-strength pressure pipeline grouting structure adopted in the present invention includes a steel lining 1, a contact grouting pipeline and a backfill grouting pipeline; The contact grouting branch pipe 3 formed by the branching of the grouting main pipe 2, the contact grouting main pipe 2 is arranged on the outer wall of the steel lining 1; the backfilling grouting pipeline includes the backfilling grouting main pipe 6 and the backfilling grouting branch pipe 7 formed by the branching of the backfilling grouting main pipe 6 , the backfill grouting main pipe 6 is arranged on the outer wall of the steel lining 1 . Due to the use of the contact grouting pipeline and the backfill grouting pipeline, the grout is poured to the set position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com