Heating system based on solid heat storage

A heating system and solid heat storage technology, applied in the field of heat storage, can solve problems such as electric energy waste, achieve the effect of simple and convenient maintenance, compact structure, and meet heating needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment structure and working principle of the present invention are further explained:

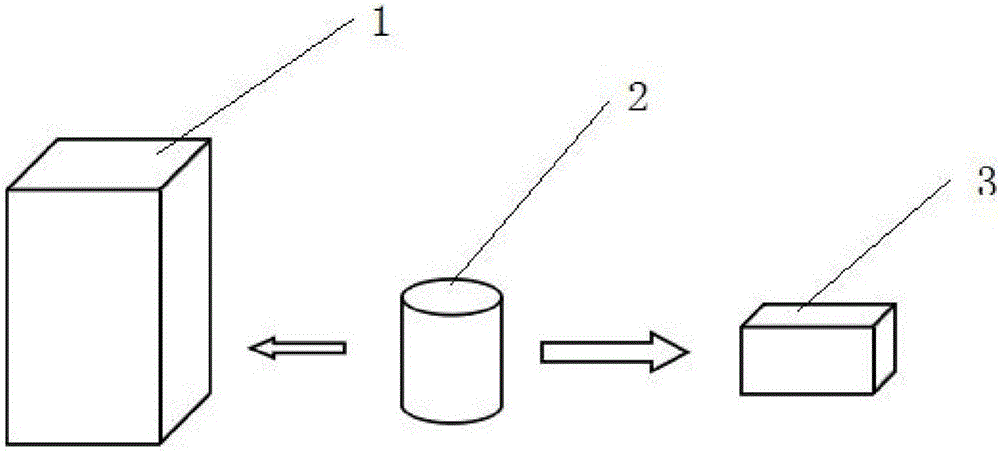

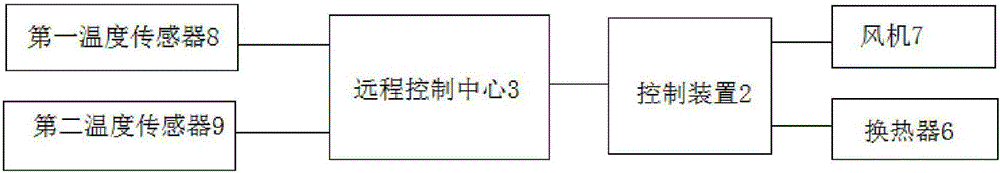

[0030] The present invention provides a heating system based on solid heat storage, such as figure 1 As shown, it includes a heat exchange device 1, a control device 2, and a remote control center 3. The remote control center 3 communicates with the control device 2 for remote control of the control device 2 to realize automatic control of the heating system. Fully automatic precise load adjustment saves labor cost.

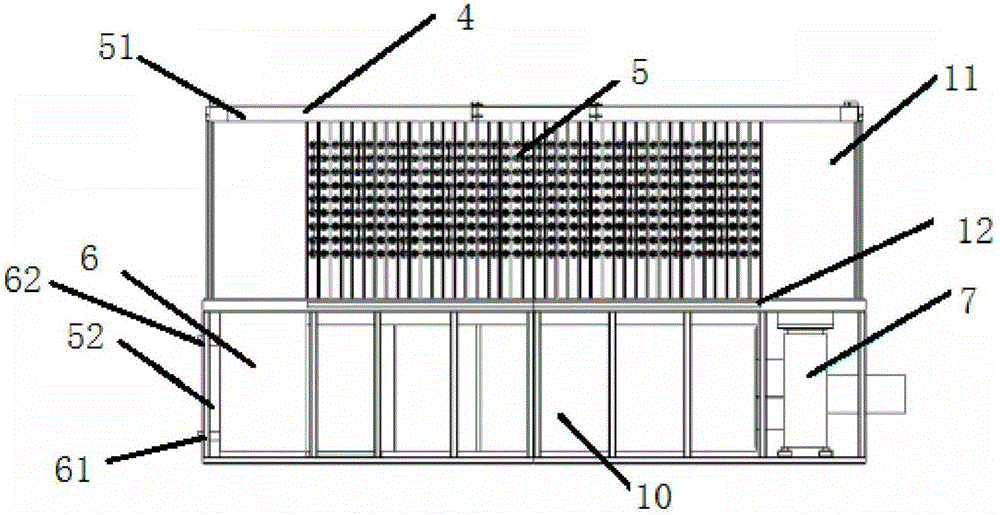

[0031] Such as figure 2 As shown, the heat exchange device 1 includes a housing 4 and a heat accumulator 5 disposed inside the housing 4, a heat exchanger 6 and a fan 7, and the fan 7 is disposed at one end of the bottom of the housing 4 to provide continuous high-temperature air . In this embodiment, the fan 7 is an automatic frequency conversion fan, and the input end of the automatic frequency conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com