A hydraulic glass detection device provided with linked light ring camera shooting, a molybdenum alloy and bearing groove corner backup plates

A glass detection and molybdenum alloy technology, applied in measuring devices, using one-time impact force to test material strength, instruments, etc., can solve problems such as operator injury, non-square, tape collapse, etc., to achieve easy removal, ensure uniform specifications, The effect of avoiding splash damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

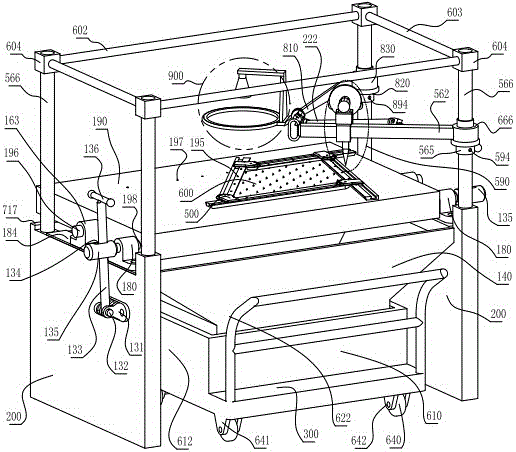

[0059] figure 1 Among them, the bearing groove corner leaning plate assembly 500 is fixed on the test bench 190, the trapezoidal glass plate 600 is fixed on the bearing groove corner leaning plate assembly 500, and the rotary impactor 590 is located directly above the trapezoidal glass plate 600 and is in working condition.

[0060] image 3 The rotary impactor 590 is out of operation directly above the trapezoidal glass plate 600 , and the halo camera assembly 900 is located directly above the trapezoidal glass plate 600 and is in a working state.

[0061] Figure 5 , the two sides of which are removed from the bearing groove corner leaning plate assembly 500, and the test table 190 is in a swinging and tilting state, which facilitates the removal of glass fragments after the trapezoidal glass plate 600 is crushed.

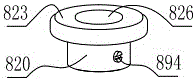

[0062] Figure 6 The camera univers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com