A glass detection device provided with a gear rotary table, a light ring for camera shooting, a copper alloy and wheel slide corner clamps

A corner jig, glass detection technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problem of unsatisfactory image digital accuracy, avoid splash damage, facilitate separation, and improve identification accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

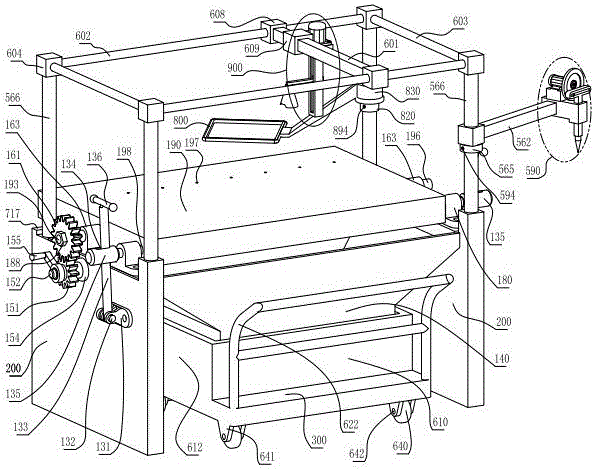

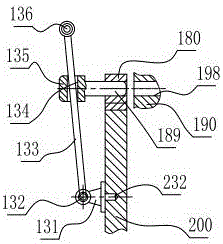

[0061] figure 1 , the wheel slide corner fixture assembly 500 is removed from the test turntable 190.

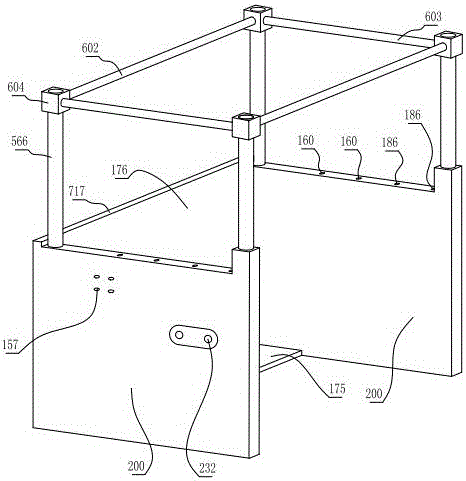

[0062] Figure 13 Among them, the wheel slideway corner fixture assembly 500 is placed on the test turntable 190, and the trapezoidal glass plate 600 is fixed, the screw lifting camera group 900 does not work when it is lifted, the moving halo 800 does not work when it is moved outward, and the rotary impactor 590 is located on the trapezoidal glass plate 600 The above is in working condition.

[0063] Figure 14 Among them, the wheel slide corner fixture assembly 500 is placed on the test turntable 190, and the trapezoidal glass plate 600 is fixed, the rotary impactor 590 is transferred out of the test turntable 190 and is in a non-working state, the screw lifting camera group 900 is in a working state, and the moving halo 800 Located right above the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com