Testing device and method for osmotic gradient of anisotropic rock mass

A technique of permeability gradient and anisotropy, which is applied in the directions of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem that the stability of underground engineering has a huge impact, cannot represent the permeability characteristics of on-site rock mass, and is very difficult to solve. Difficult to popularize and apply and other issues, to avoid large-scale pressure water testing in the region, reduce technical difficulty and test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

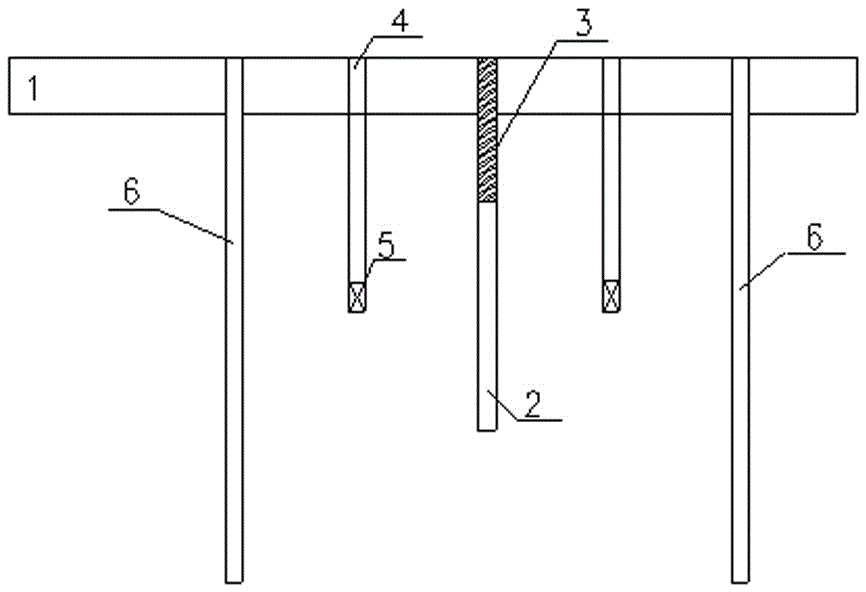

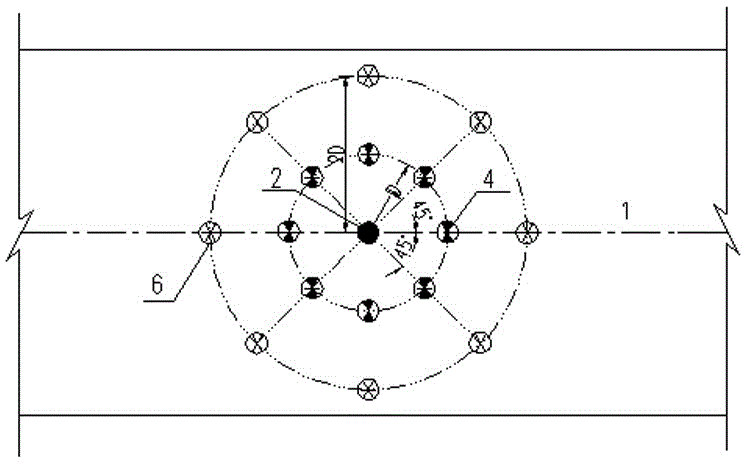

[0034] Refer to attached picture.

[0035] The anisotropic rock mass permeability gradient testing device of the present invention comprises a reinforced concrete bottom plate 1 arranged on a test site, and a pressurized water hole 2 is arranged in the center of the test site, and the depth of the pressurized water hole 2 is 8-10m. In this embodiment, 8m is used, and a plug 3 is arranged between the orifice of the pressurized water hole 2 and the bottom plate 1, and seepage holes 4 are arranged around the pressurized water hole 2 at intervals of 45°. The bottom of 4 is provided with a piezometer 5, and the periphery of the pressure hole 4 is arranged with curtain grouting holes 6, and the curtain grouting holes 6 are distributed in a ring shape.

[0036] While adopting the above technical solution, the present invention can also adopt or combine the following further technical solutions: the depth of the pressure seepage hole 4 is smaller than the depth of the pressure water h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com