Protecting method of optical-fiber grating sensor attached to surface of composite-material structure

A composite material, fiber grating technology, applied in the direction of optical testing flaws/defects, can solve the problems of affecting the structural performance of composite materials, cumbersome operation, reducing periodic inspections, etc., to avoid personnel safety accidents and economic losses, and the process is simple. , Reduce the effect of periodic inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

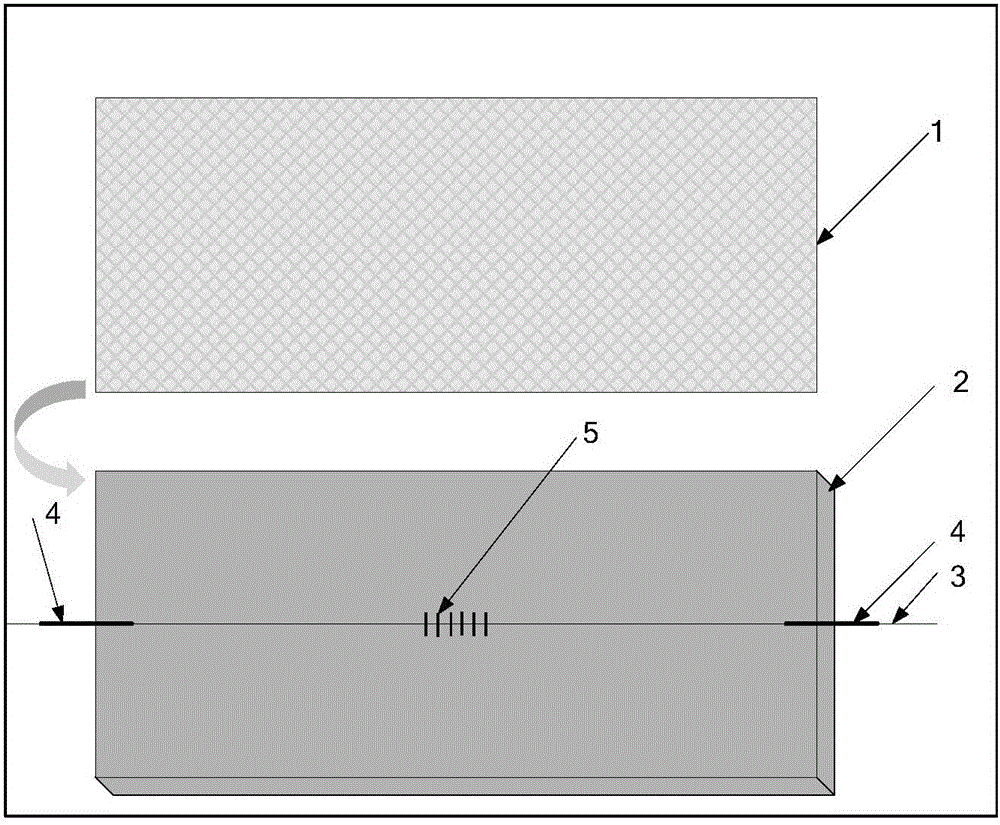

[0027] refer to figure 1 , a surface-attached fiber grating sensor protection method for a composite material structure, the specific implementation steps are as follows:

[0028] 1. Fix the composite material laminate 2 horizontally on the workbench;

[0029] 2. Cover both ends of the fiber grating sensor 5 with a protective sleeve 4, and place it on the surface of the composite laminate 2. The sleeve extends into the end face of the composite laminate 2 by 10 mm, and connects the optical fiber and the sleeve with quick-drying glue Fix at the place, and evenly apply 0.5mm thick adhesive on the surface of the laminate to fix the optical fiber 3 and the protective sleeve 4;

[0030] 3. Lay the glass fiber cloth 1 neatly on the adhesive, install a putty strip around the fiber cloth, fix the special film for vacuuming with the putty strip, and use a vacuum device to v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com