Automatic electric leakage detection platform for electric leakage circuit breaker

A leakage circuit breaker and leakage detection technology, which is applied in the parts, instruments, and measurement of electrical measuring instruments, etc., can solve the problems of error in detection results, high resistance of screw materials, and low detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

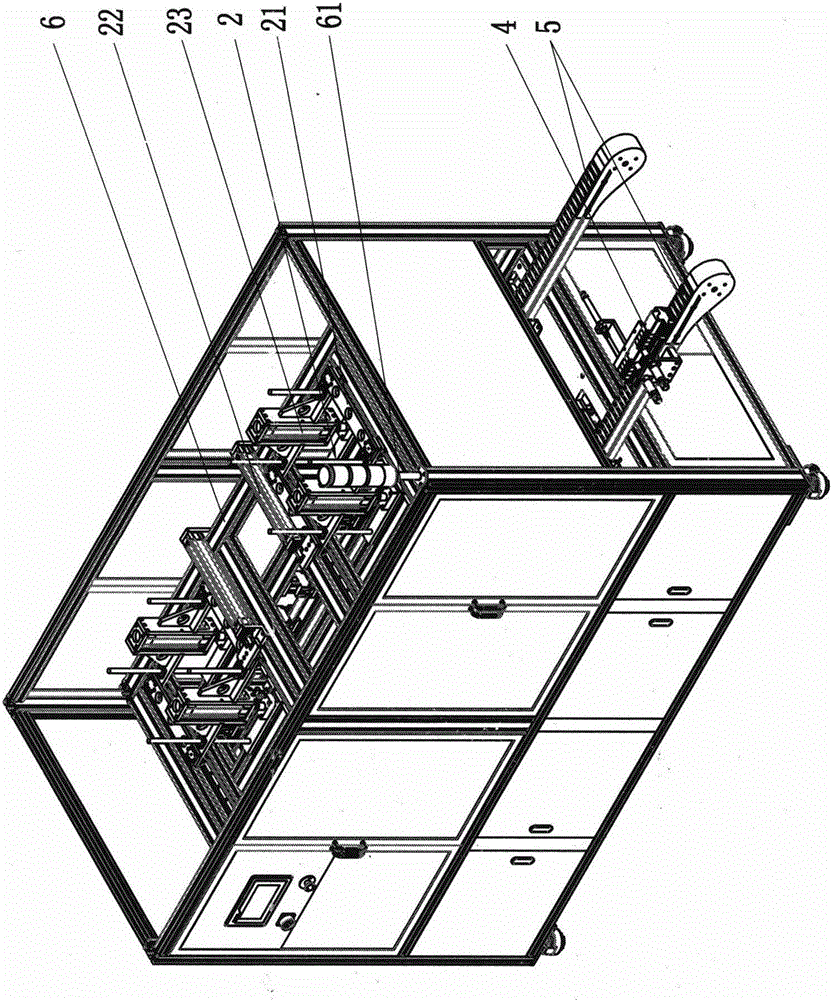

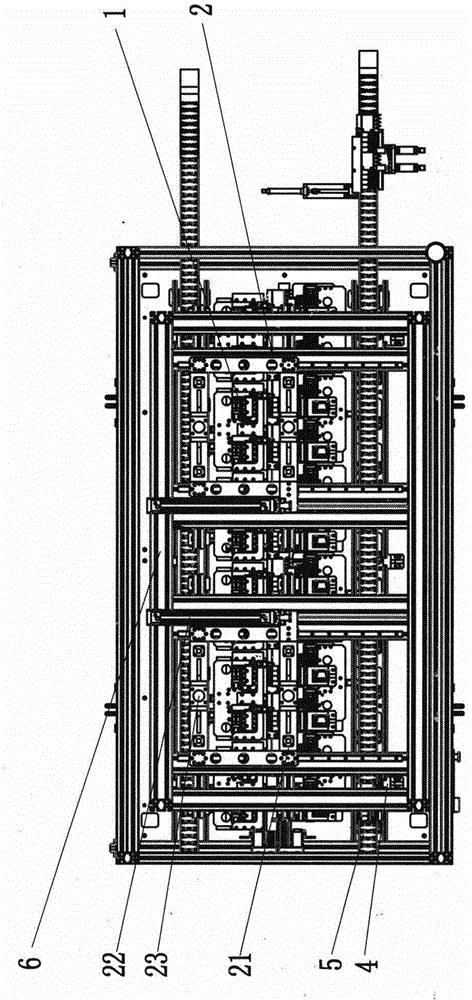

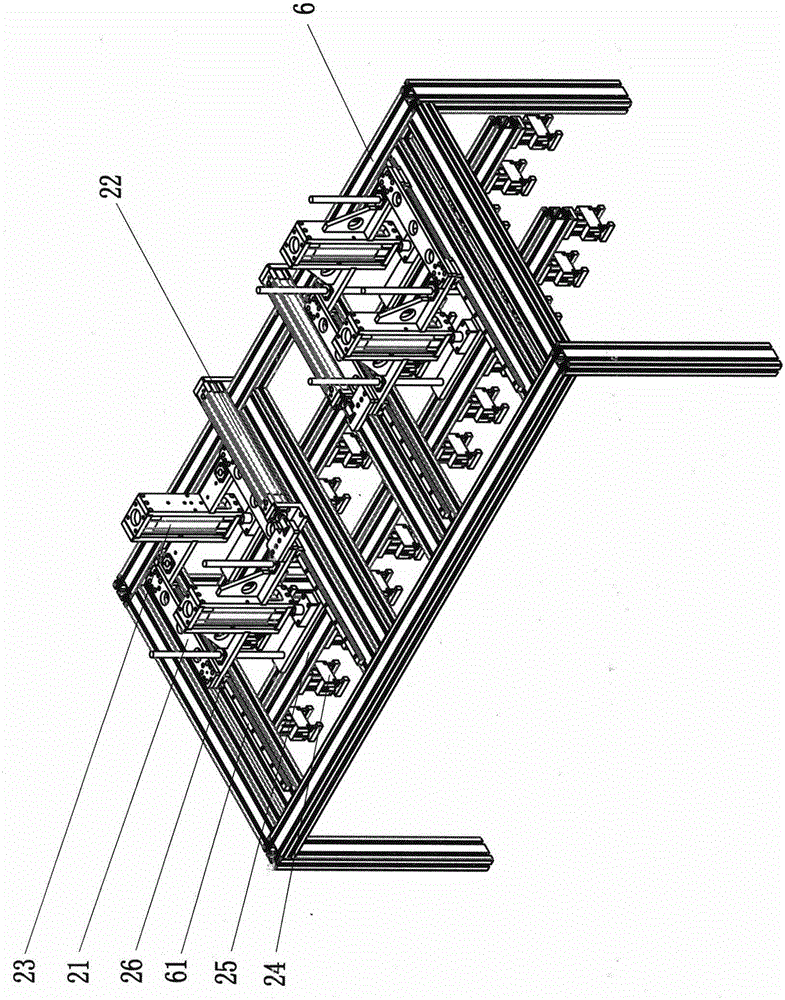

[0023] Such as Figure 1-Figure 6 As shown, the specific embodiment of the present invention is an automatic leakage detection platform for leakage circuit breakers, including a frame 6, a conveyor belt 5, a loading platform 4, a manipulator 2, a positioning platform 3, a detection fixture 1, a conveyor belt 5, and a loading platform 4 , positioning table 3, and detection fixture 1 are all arranged in the frame 6, and the positioning table 3 is arranged in the middle of the detection fixture 1, and two conveyor belts 5 are respectively arranged on both sides of the detection fixture 1, and the distance between the two conveyor belts 5 and the positioning table 3 Equal, loading table 4 is arranged on conveyor belt 5 and moves with conveyor belt 5, and frame 6 is provided with guide rail 61 perpendicular to conveyor belt 5, and manipulator 2 is connected on guide rail 61 and slides, and manipulator 2 includes manipulator bracket 21, traverse mechanism 22 , the lifting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com