A light guide plate with a positioning structure and its molding process

A technology of positioning structure and light guide plate, applied in the field of light guide plate, can solve the problems of cumbersome production steps, insufficient uniformity of light guide, inconvenient array connection, etc., and achieves the effects of simple structure, small occupied space and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

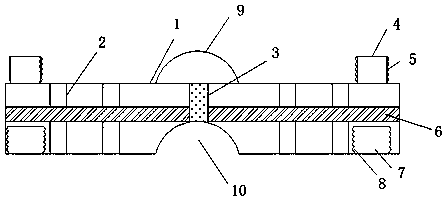

[0017] The present invention provides a light guide plate with a positioning structure, including a light guide plate body 1, a fixing block 9 is provided in the middle of the upper end of the light guide plate body 1, and the middle portion of the lower end of the fixing block 9 is connected to the arc through a limiting hole 3. The upper end of the shaped groove 10, and the fixed block 9 matches the arc groove 10, the upper end of the light guide plate body 1 is provided with light-transmitting blocks 4 on the left and right sides, and the outer side of the light-transmitting block 4 is provided with protrusions 5. The left and right sides of the lower end of the light guide plate body 1 are provided with limiting grooves 7 that match the light-transmitting block 4 , and the inner cavity of the limiting groove 7 is provided with a groove 8 that matches the protrusion 5 . The inner cavity of the light guide plate body 1 is vertically and equidistantly provided with astigmatism...

Embodiment 2

[0024] The present invention provides a light guide plate with a positioning structure, including a light guide plate body 1, a fixing block 9 is provided in the middle of the upper end of the light guide plate body 1, and the middle portion of the lower end of the fixing block 9 is connected to the arc through a limiting hole 3. The upper end of the shaped groove 10, and the fixed block 9 matches the arc groove 10, the upper end of the light guide plate body 1 is provided with light-transmitting blocks 4 on the left and right sides, and the outer side of the light-transmitting block 4 is provided with protrusions 5. The left and right sides of the lower end of the light guide plate body 1 are provided with limiting grooves 7 that match the light-transmitting block 4 , and the inner cavity of the limiting groove 7 is provided with a groove 8 that matches the protrusion 5 . The inner cavity of the light guide plate body 1 is vertically and equidistantly provided with astigmatism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com