Polarization-insensitive micro-ring filter based on silicon nanowire waveguide

A polarization-insensitive, silicon nanowire technology, used in light guides, instruments, optics, etc., can solve problems such as increasing device size and increasing system complexity, reducing complexity and improving flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

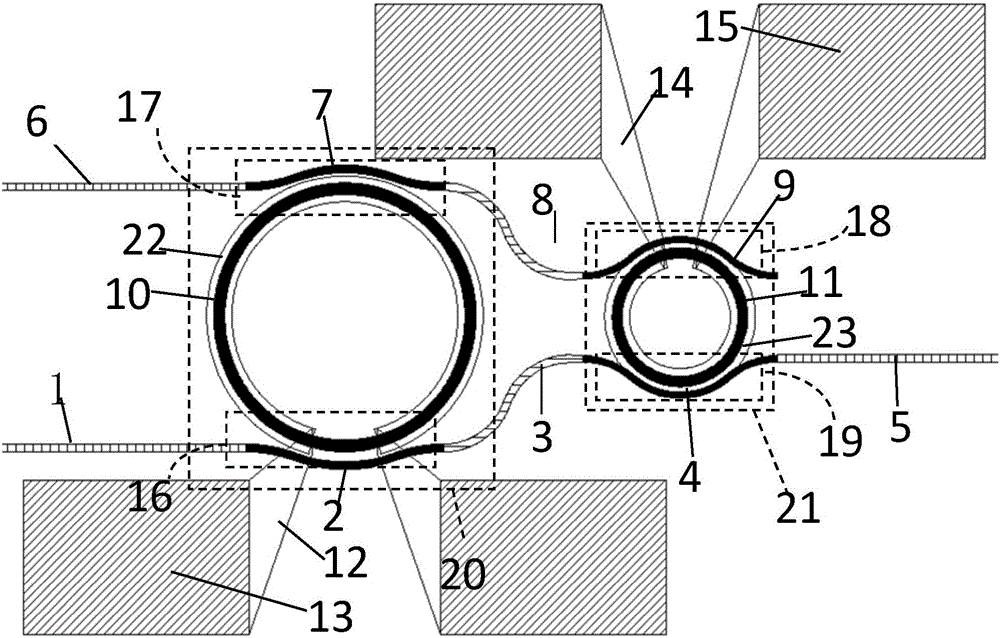

[0037] Such as figure 1 As shown, the first embodiment includes a connected first microring filter 20 and a second microring filter 21 and metal electrodes, the first microring filter 20 includes a first ring waveguide 10 and a symmetrically placed ring waveguide The first curved waveguide 2 and the third curved waveguide 7 on both sides of 10, the microring adopts a single first ring waveguide 10, and the second microring filter 21 includes the second ring waveguide 11 and the second The second curved waveguide 4 and the fourth curved waveguide 9 on both sides of the ring waveguide 11, wherein the micro-ring adopts a single second ring waveguide 11. The first ring waveguide 10 and the second ring waveguide 11 adopt a single microring structure.

[0038] The input waveguide 1, the first curved waveguide 2, the first adiabatic connection waveguide 3, the second curved waveguide 4 and the first output waveguide 5 are connected end to end, and are located on the same side of the...

Embodiment 2

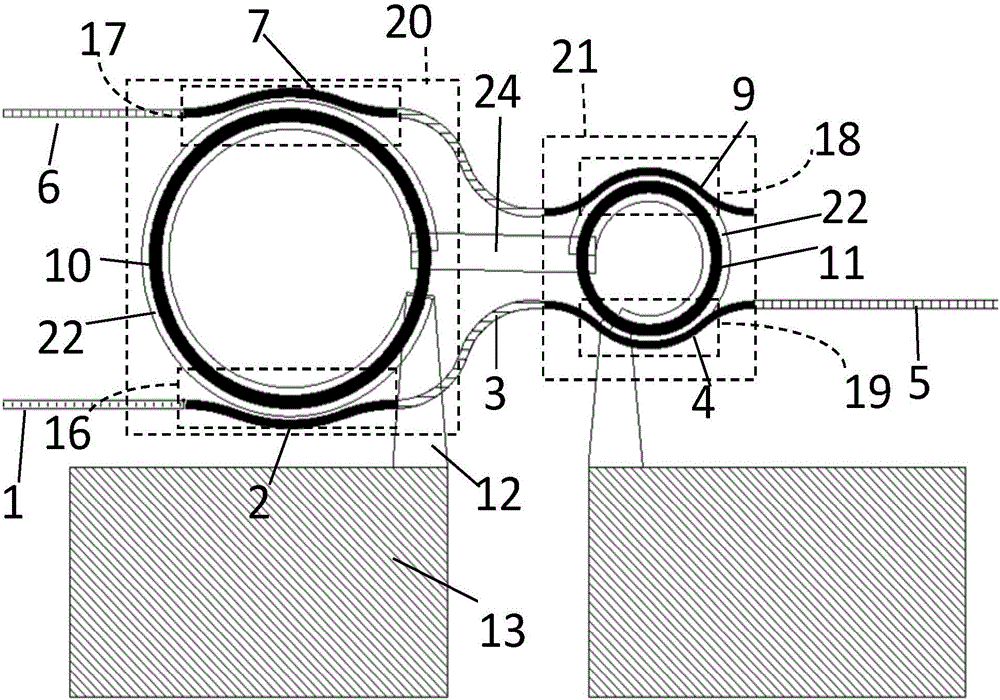

[0045] Such as figure 2 As shown, the second embodiment includes a connected first microring filter 20 and a second microring filter 21 and metal electrodes. The first microring filter 20 includes a first ring waveguide 10 and a symmetrically placed ring waveguide The first curved waveguide 2 and the third curved waveguide 7 on both sides of 10, the microring adopts a single first ring waveguide 10, and the second microring filter 21 includes the second ring waveguide 11 and the second The second curved waveguide 4 and the fourth curved waveguide 9 on both sides of the ring waveguide 11, wherein the micro-ring adopts a single second ring waveguide 11. The first ring waveguide 10 and the second ring waveguide 11 adopt a single microring structure.

[0046] The input waveguide 1, the first curved waveguide 2, the first adiabatic connection waveguide 3, the second curved waveguide 4 and the first output waveguide 5 are connected end to end, and are located on the same side of t...

Embodiment 3

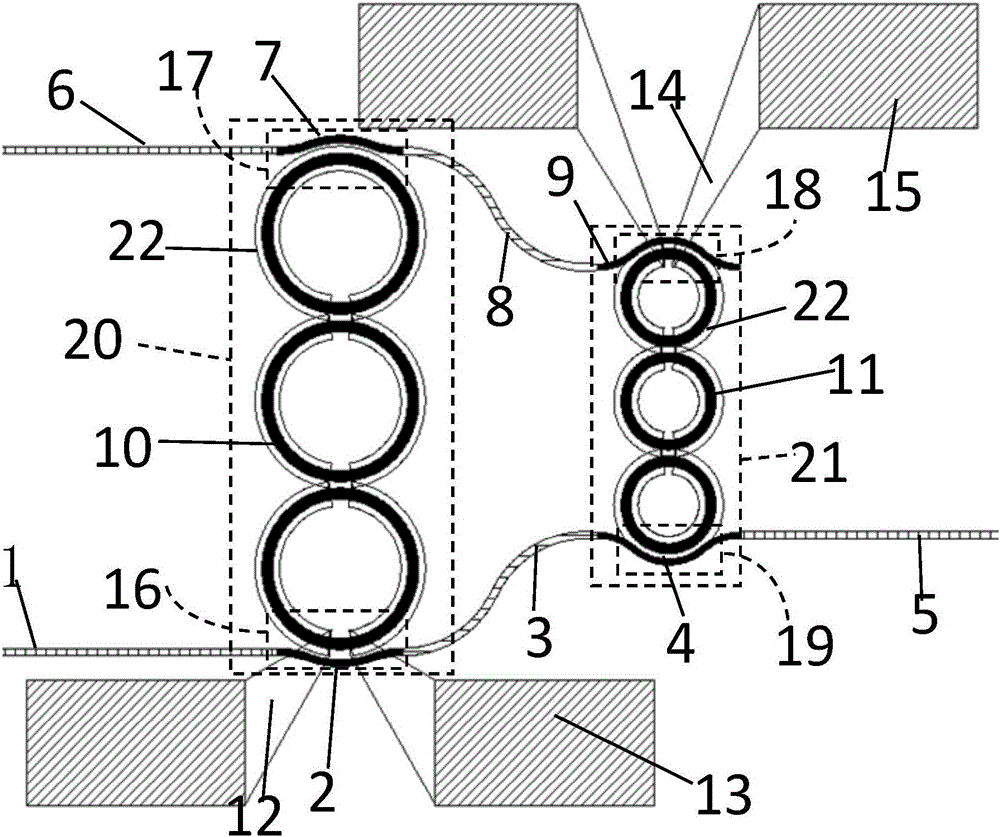

[0049] Such as figure 1 As shown, the third embodiment includes a first micro-ring filter 20, a second micro-ring filter 21 and metal electrodes connected to each other. The first micro-ring filter 20 includes three cascaded first ring waveguides 10 and symmetrically arranged The first curved waveguide 2 and the third curved waveguide 7 on both sides after cascading the first ring waveguide 10, the second microring filter 21 includes three cascaded second ring waveguides 11 and the second ring waveguide symmetrically placed 11 After cascading, the second curved waveguide 4 and the fourth curved waveguide 9 on both sides. The first ring waveguide 10 and the second ring waveguide 11 adopt a cascaded structure of multiple microrings.

[0050] The input waveguide 1, the first curved waveguide 2, the first adiabatic connection waveguide 3, the second curved waveguide 4 and the first output waveguide 5 are connected end to end, and are located on the same side after the first ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com