Optimization method and device of single-impact stress screening condition

A technology of impact stress and screening conditions, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as limited application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

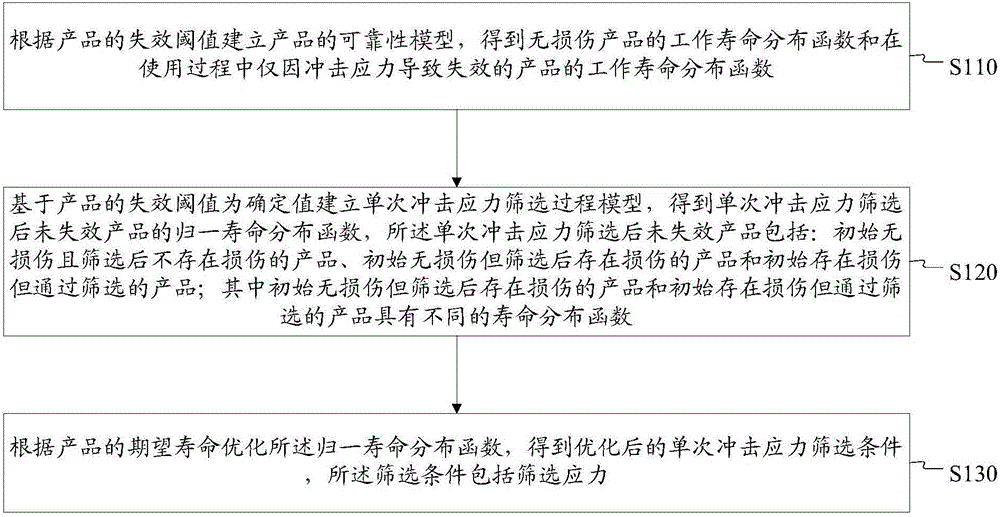

[0062] figure 1 The flow chart of the optimization method for the single impact stress screening conditions provided in this embodiment, such as figure 1 As shown, the method includes:

[0063] S110, establishing a reliability model of the product according to the failure threshold pair of the product, and obtaining a working life distribution function of the non-damaged product and a working life distribution function of the product failing only due to impact stress during use.

[0064] During the product manufacturing process, due to non-standard materials or other factors, some products with potential defects and damages (such as microcracks) may be produced. These defective products are prone to failure due to accumulated damage during use. Compared with products without potential defects and damages, there is an additional failure mode—the mode of failure due to cumulative damage, so this embodiment establishes The product reliability model distinguishes non-damaged pro...

Embodiment 2

[0121] The optimization method of multiple impact stress screening conditions in Example 1 is applicable to the common situation where the initial non-damaged products and the initially intact products with defects after screening have different life functions, especially suitable for the damage size caused by impact stress conforming to normal distributed products. For example, when a solder joint with microcracks receives an external impact, the crack will gradually expand, and when the crack size reaches a certain limit, the fracture will fail. Therefore, the optimization method for the single impact stress screening condition in Example 1 can be used for solder joints. Point single impact stress screening.

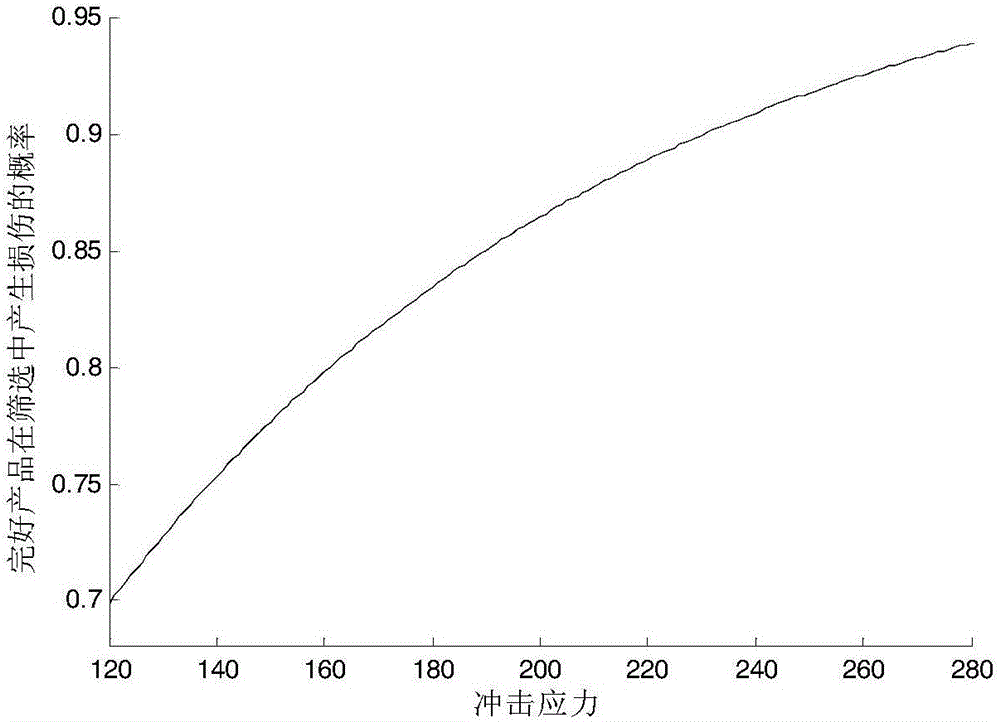

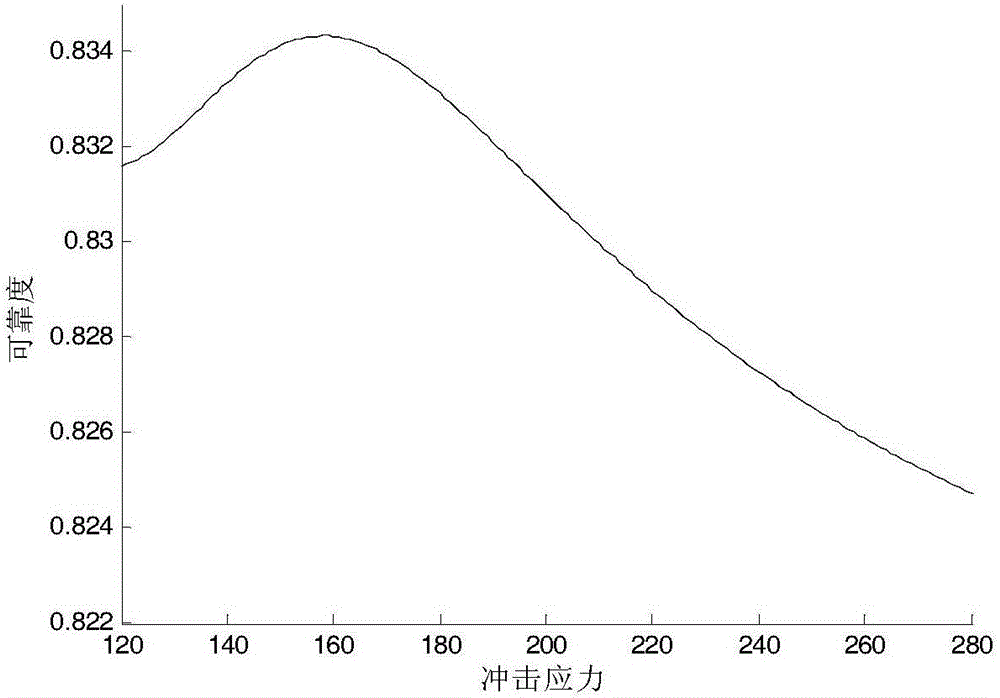

[0122] When modeling the single impact stress screening process, it is assumed that the base failure rate of undamaged products is r(t)=0.001, the non-homogeneous Poisson distribution strength function λ(t)=0.001, and the failure threshold D w = 4, the proportion of i...

Embodiment 3

[0127] This embodiment adopts the same design concept as that of the first embodiment, and provides an optimization device for single impact stress screening conditions.

[0128] Figure 4 The optimization device structure block diagram of the single impact stress screening condition that this embodiment provides, as Figure 4 As shown, the device includes:

[0129] The reliability modeling unit 41 is used to establish a reliability model of the product according to the failure threshold of the product, and obtain the distribution function of the working life of the product without damage and the distribution function of the working life of the product that fails only due to impact stress during use.

[0130] Among them, the working life distribution function of non-damaged products is specifically

[0131] The working life distribution function of the product that fails only due to impact stress during use is specifically:

[0132] T in the above formula N is the life...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com