Three-dimensional reconstruction method for sinter microstructure diagram

A 3D reconstruction and microstructure technology, applied in 3D modeling, image data processing, instruments, etc., can solve the problems of expensive equipment, complicated operation, and low image resolution, and achieve the effect of improving precision and reconstruction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A 3D reconstruction method of sinter microstructure map. The concrete steps of described three-dimensional reconstruction method are:

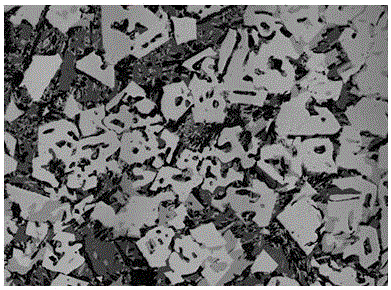

[0034] Step 1. Select an area on the surface of the sintered ore as the surface to be reconstructed, and use a metallographic microscope to photograph the surface to be reconstructed to obtain the following: figure 1 The set of micrographs of sinter shown. Then use the filter method to smooth the sinter microscopic picture set, and then splicing and merging to get the following figure 2 The 2D microstructural diagram of the sinter fault sequence shown.

[0035] The magnification of the metallographic microscope is n times, and n is 40.

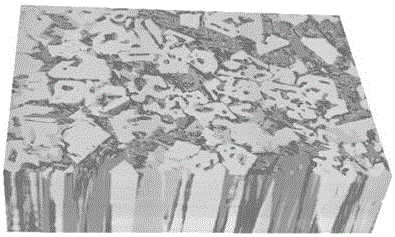

[0036] Step 2. Use 3D Slicer software to perform 3D reconstruction on the 2D microstructural diagram of the sinter fault sequence described in Step 1 using volume rendering technology to obtain the following: image 3 The volume rendering 3D reconstruction of sinter microstructure is shown.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com