Transformer installing mechanism

An installation mechanism and technology for transformers, which are applied in the directions of transformer/reactor installation/support/suspension, substations mounted on columns, etc., can solve problems affecting the structural stability of transformers, and achieve the effect of good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

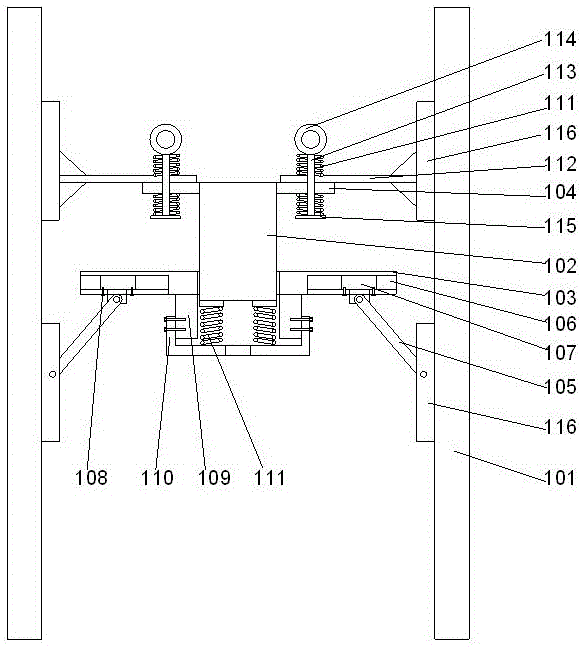

[0023] Such as figure 1 As shown, a transformer installation mechanism includes four rod bodies 101 and a transformer body 102 arranged between the rod bodies 101. A mounting plate 103 is provided at the lower end of the transformer body 102. A fixed plate 104 is arranged on the outer side of the upper end, and a strut 105 is respectively arranged on the inside of the two described rod bodies 101, and the lower ends of the described strut rods 105 are hinged on the described rod body 101, and on the lower end surface of the described mounting plate 103 Four T-shaped slots 106 are provided, and a T-shaped slide block 107 is provided at the upper end of the pole 105, and the slide block 107 can slide along the T-shaped slot 106. A threaded hole is provided on the side wall of the T-shaped groove 106, and a positioning bolt 108 is arranged in the described threaded hole, and the described positioning bolt 108 is threadedly connected in the threaded hole on the described T-shaped ...

Embodiment 2

[0028] In this embodiment, on the basis of Embodiment 1, preferably, the fixed pin 114 is threadedly connected to the vertical rod 113, and the gap between the fixed pin 114 and the upper end surface of the upper beam 112 is A high-strength spring 111 is sleeved on the pole 113 .

[0029] By adopting the high-strength spring structure, there is a certain space between the fixed pin and the upper beam, and the high-strength spring is used to buffer the force of the rod body on the upper beam, so that the lower end of the vertical rod is under the elastic force of the high-strength spring. Driven by the upper beam, it will shake relatively, so that it has better stability. At the same time, the high-strength spring is used to make the transformer body have more room to move upward.

[0030] In this embodiment, further preferably, the lower end of the vertical rod 113 runs through the upper beam 112, and a disc 115 is arranged at the end of the vertical rod 113, and the disc 115 ...

Embodiment 3

[0032] In this embodiment, in order to facilitate the installation of the upper beam, preferably, a channel steel 116 is arranged on the rod body 101, and the length direction of the channel steel 116 is parallel to the length direction of the rod body 101. The channel steel 116 is provided with at least 2 sets of through holes along the length direction of the channel steel 116, and the upper beam 112 is fixedly connected to the channel steel 116 through the bolts passing through the through holes. In this embodiment, a reinforcing rib structure may be provided under the upper beam, so that the reinforcing rib, the upper beam, and the rod body form a triangular structure of legs.

[0033] By using channel steel, it can be easily installed on the rod body, so that the two parallel end faces are used as the supporting structure for installing the upper beam, and multiple sets of bolts are used to penetrate the two opposite end faces of the channel steel to fix and fix the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com