Transparent material defect analysis method

A technology for transparent material and defect analysis, which is applied in the fields of material analysis using radiation, electrical components, semiconductor/solid-state device manufacturing, etc. Difficult to obtain physical maps and other issues, to achieve ideal results, high accuracy, and easy analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

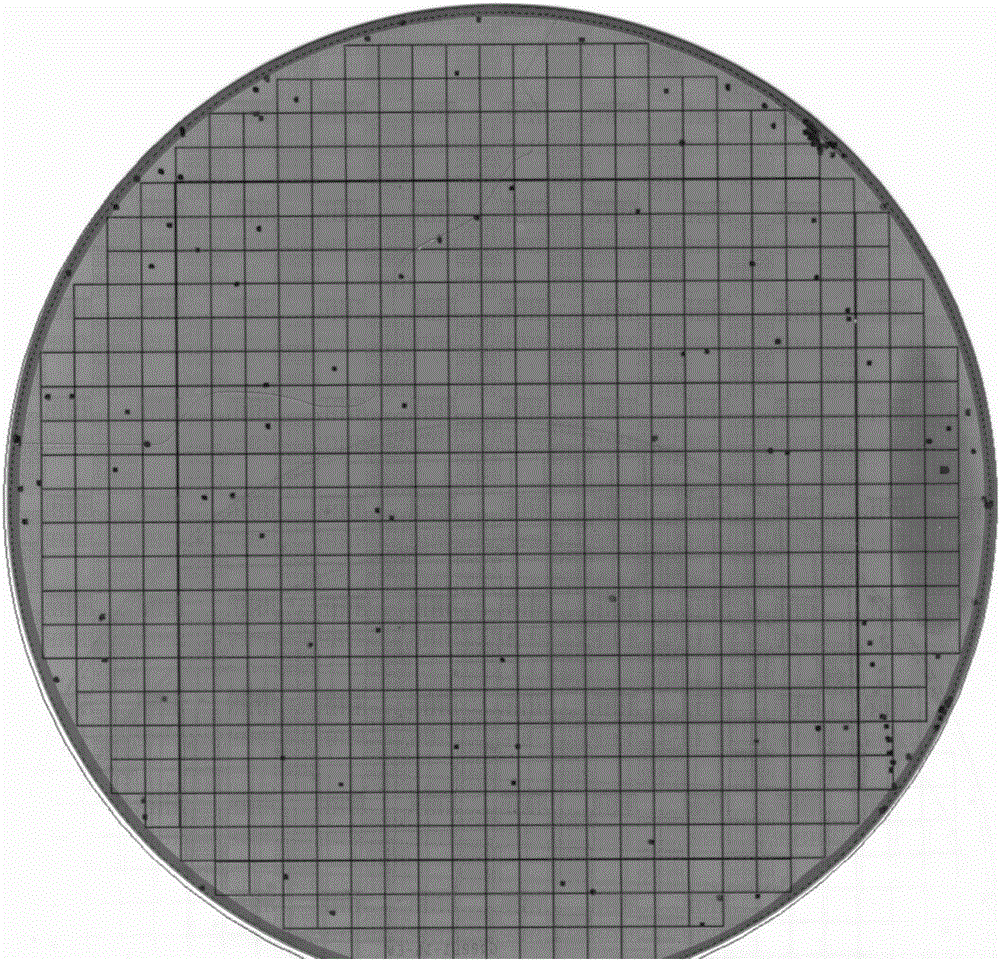

[0022] The defect analysis method of a transparent material in this embodiment first provides a transparent material to be analyzed, conducts microscopic defect detection on the transparent material to obtain a defect distribution map, and then attaches the transparent material to the defect distribution map through alignment , use the scanner to scan the image to obtain the object-result comparison chart, and analyze the correlation between the defect and the appearance of the transparent material through the object-result comparison chart.

[0023] The micro-defect detection of transparent materials is to scan the surface of transparent materials by laser, and obtain the specific distribution of various micro-defects by detecting scattering intensity, shape change, surface reflectivity and phase migration, etc. Matched defect distribution map. The defect distribution map is preferably a coordinate map, which is arranged by latitude and longitude lines and vertically intersec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com