Sorting and carrying AGV

A chassis and drive mechanism technology, applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of limited logistics handling efficiency, low positioning accuracy, and cargo drop, so as to improve logistics handling efficiency, The effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

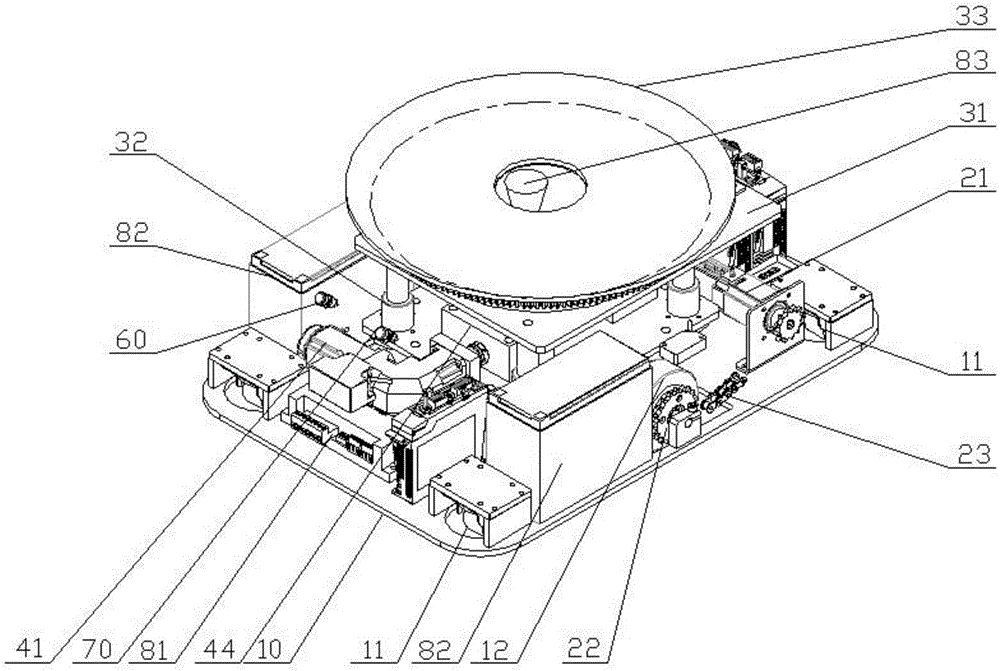

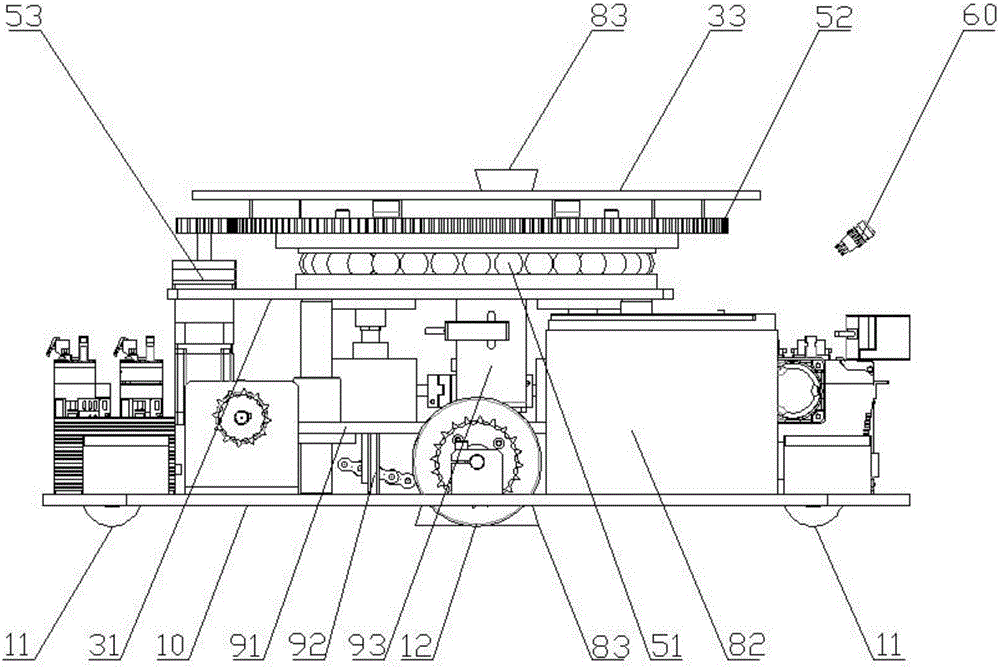

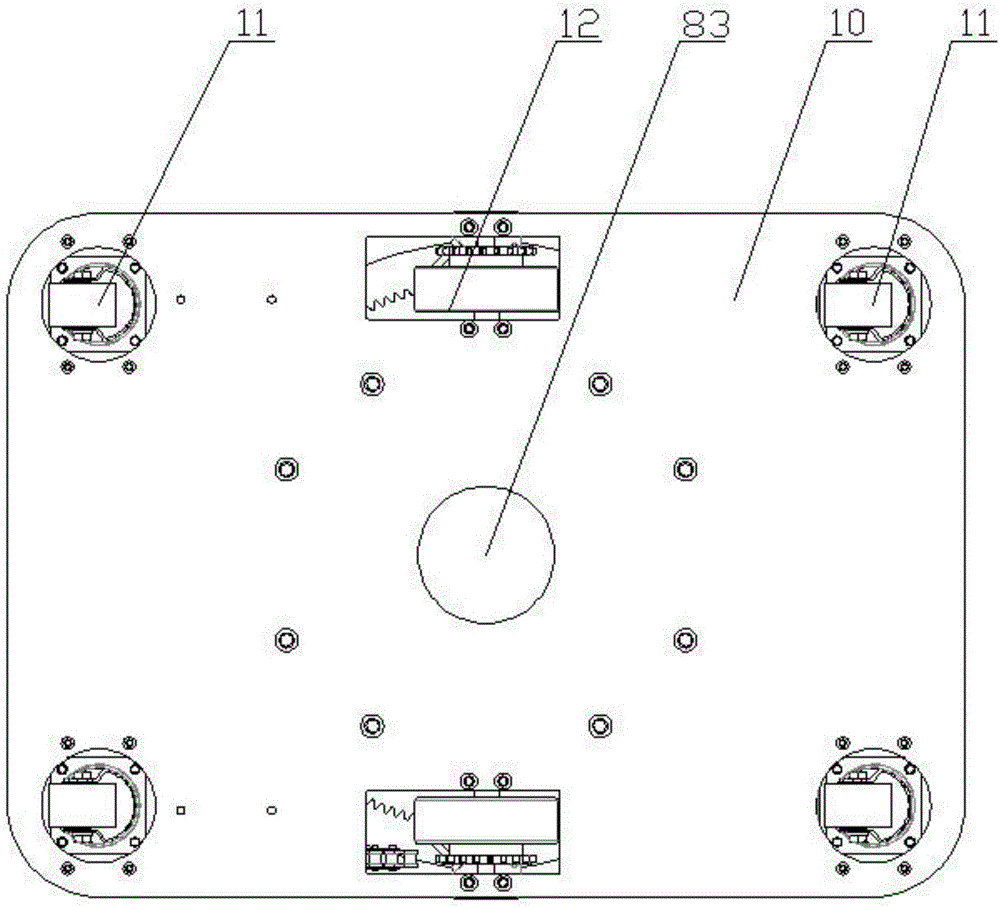

[0029] see Figure 1 to Figure 3 A sorting and handling AGV vehicle described in a preferred embodiment of the present invention includes a chassis 10, two driven wheels 11 are respectively provided at the front and rear ends of the chassis 10, driving wheels 12 are respectively provided on both sides of the middle part of the chassis 10, and two A first drive mechanism that drives the two driving wheels 12 to rotate respectively. Specifically, the two first driving mechanisms both include a first motor 21 and a gear 22 coaxially connected with the drive wheel 12 , and the transmission between the first motor 21 and the gear 22 is through a chain 23 . It can be seen that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com