Rock tension shear test device and method used in tension shear test machine

A testing device and testing machine technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/compression, measuring devices, etc., can solve the problem of high cost, unguaranteed test accuracy, and control Problems such as the poor effect of the system hydraulic jack on stabilizing the load, etc., achieve the effect of low cost, guaranteed accuracy of test results, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

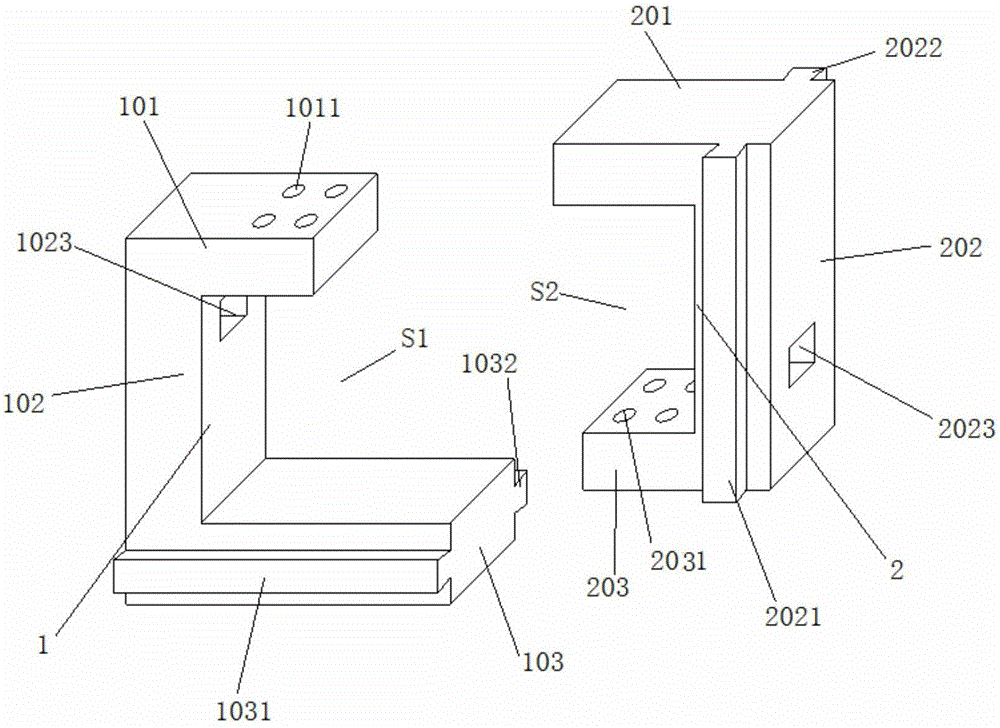

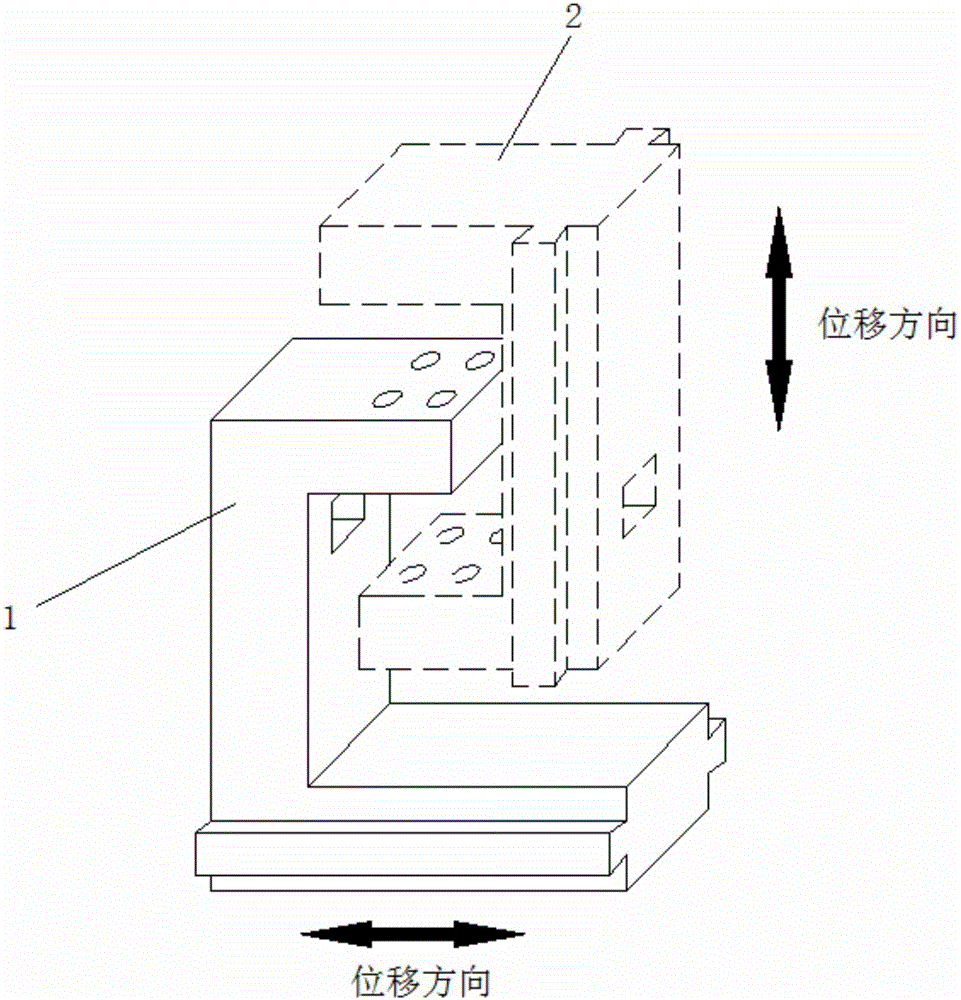

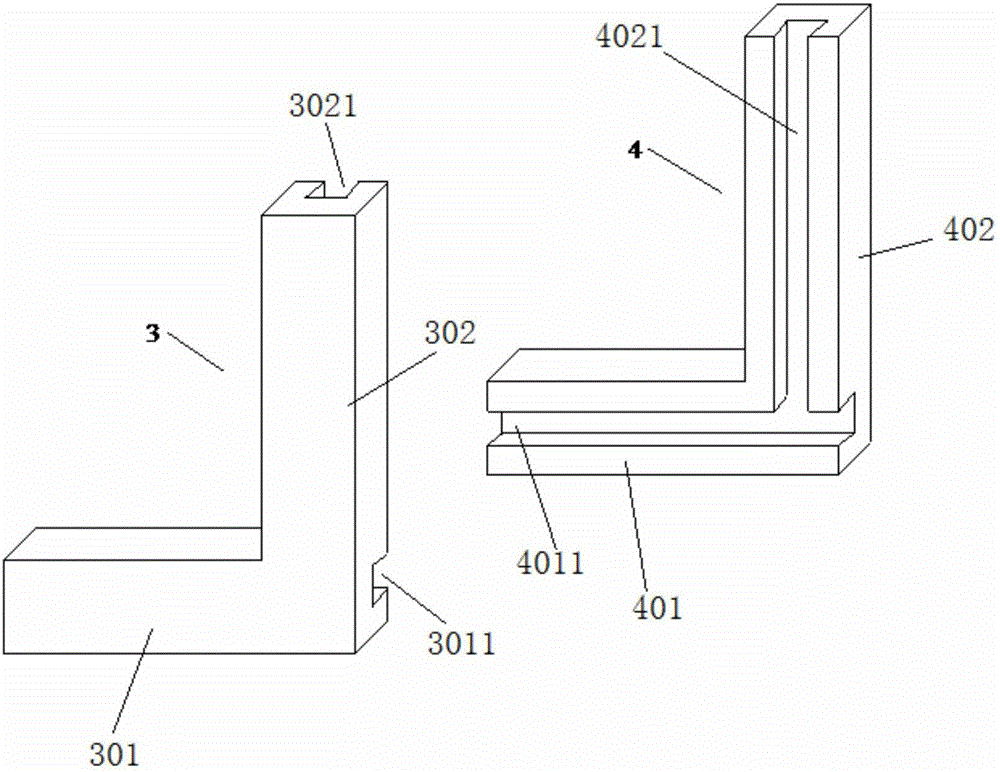

[0052] A rock tension-shear test device that can be used on a compression-shear tester, see Figure 7 , including 匚-shaped tensile piece Ⅰ1, 匚-shaped tensile piece Ⅱ2, L-shaped guide slide Ⅰ3, L-shaped guide slide Ⅱ4, testing machine loading head Ⅰ91, testing machine loading head Ⅱ92, testing machine loading head Ⅲ93 and testing machine Loading head Ⅳ94

[0053] see figure 1 , the U-shaped tensile member I1 is composed of a top plate I101, a column I102 and a bottom plate I103, and the three enclose and semi-enclose the space IS1. The top plate I101 is shorter than the bottom plate I103.

[0054] The top plate I101 has several threaded holes I1011 running through its upper and lower surfaces.

[0055] The column I102 is provided with a square through hole I1023 running through both sides thereof. An outlet of the square through hole I1023 is in the semi-enclosed space IS1.

[0056] The two sides of the bottom plate I103 have slide rails I-I1031 and slide rails I-II1032 resp...

Embodiment 2

[0073] This embodiment adopts the device of embodiment 1, during the test:

[0074] 1) see Figure 4 , put the rock specimen 8 in the space S.

[0075] In the embodiment, high-strength structural glue can be used to paste the two connecting plates on the upper and lower sides of the rock specimen 8 respectively, and wait for the glue to fully exert its strength (generally at least 24 hours).

[0076] 2) see Figure 7 , apply a predetermined normal force to the rock specimen 8 through the loading head I91 of the testing machine. That is, the loading head I91 of the testing machine is pressed to the U-shaped tensile member II2, and the rock specimen 8 is stretched up and down by the connection blocks 6 / 60 bonded to its upper and lower ends respectively.

[0077] It is worth noting that the bottom of the U-shaped tensile member II2 is suspended, and when the loading head I91 of the testing machine applies a downward force, if the rock breaks, the U-shaped tensile member II2 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com