Decanting-type waste muddy water recycling pool

A recovery tank and sludge water technology, which is applied in the direction of settling tank, sedimentation regulating device, feeding/discharging device of settling tank, etc., can solve the problems of large fluctuations in water quality of recycled water, poor water separation effect, and poor secondary utilization effect and other problems, to achieve the effect of low engineering cost and operating cost, simple structure and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

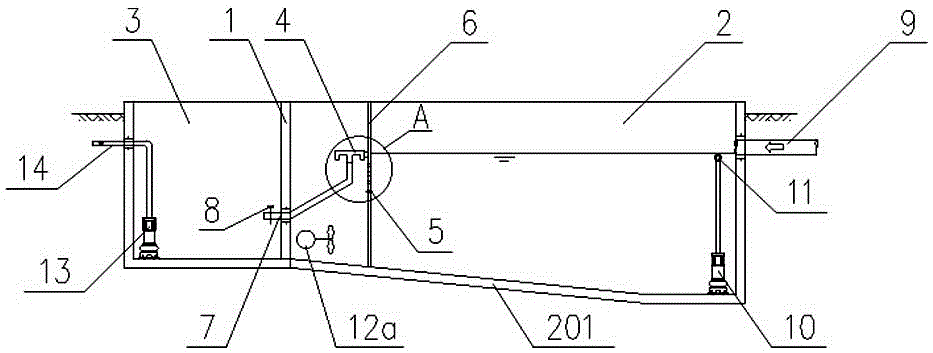

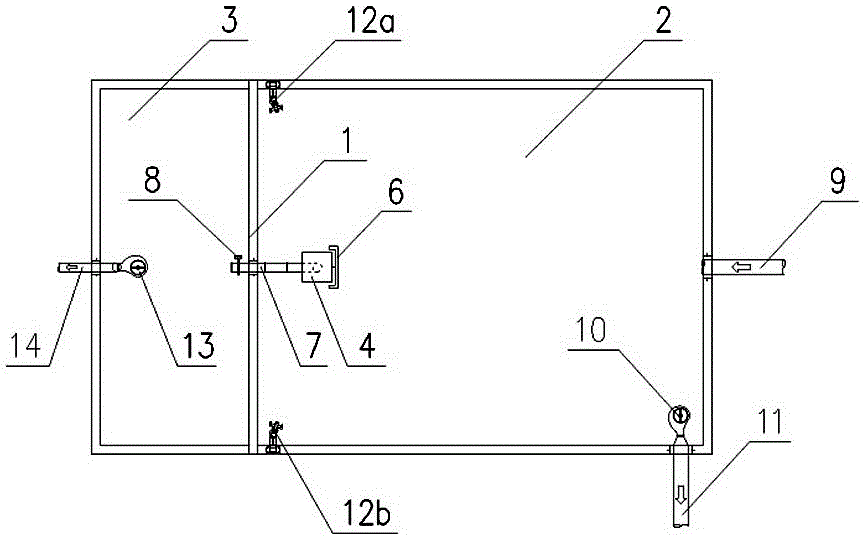

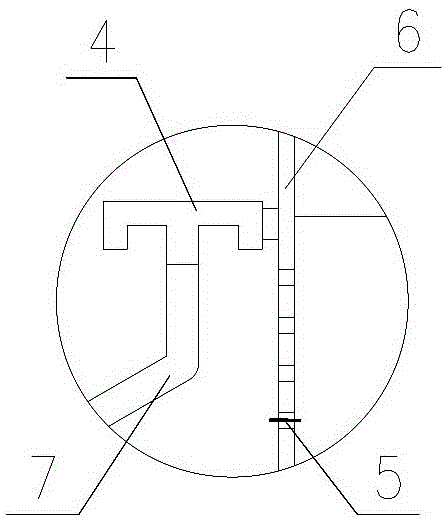

[0010] Such as Figure 1-3 As shown, the decanting waste sludge water recovery tank of the present invention comprises a steel concrete structure recovery tank body, in which a partition wall 1 is arranged, and the partition wall 1 divides the recovery tank body into a sedimentation area 2 and a water collection area 3. The bottom wall 201 of the sedimentation zone 2 is arranged gradually downward along the partition wall 1 toward the opposite pool wall, which is beneficial for the sedimentation to flow to the sludge outlet pipe 11 along the inclined direction of the bottom wall 201 . A buoy type decanter 4 and a movable insert limit pin 5 are installed near the partition wall 1 in the sedimentation area 2 (such as image 3 Shown) the vertical guide rail 6, the buoy of the buoy type water decanter 4 is slidably connected with the vertical guide rail 6, and the water outlet of the buoy type water decanter 4 is connected with the water guide pipe 7. The above-mentioned vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com