Biomass ash-based semidry process desulfurization and denitrification system and method

A semi-dry desulfurization and biomass ash technology, applied in the field of flue gas pollution control, can solve the problems of ineffective utilization of biomass ash and energy waste, reduce the generation of wastewater and solid waste, reduce disproportionation reactions, and apply promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

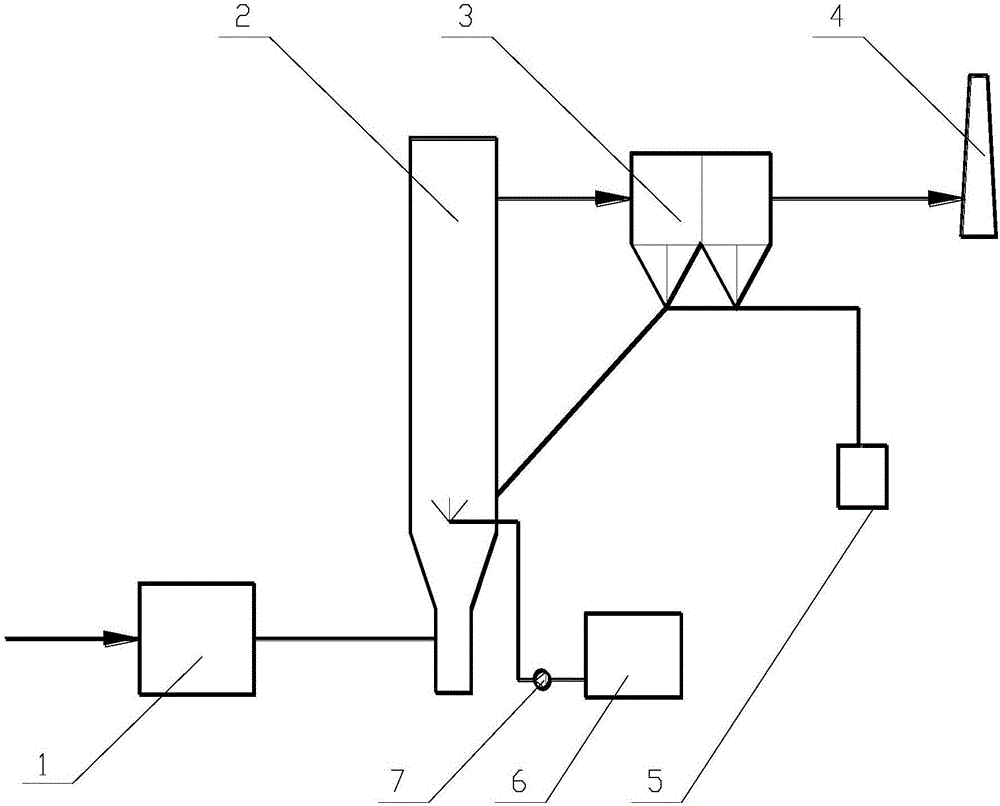

[0042] Such as figure 1 As shown, a semi-dry desulfurization and denitrification system based on biomass ash includes an oxidation device 1, a semi-dry purification tower 2, a dust collector 3, and a chimney 4. The oxidation device 1 communicates with the semi-dry purifier 2 for Provide oxides that oxidize nitrogen oxides, the semi-dry purification tower 2 is connected with the flue gas source, and is used for semi-dry desulfurization and denitrification of the flue gas, and the dust collector 3 is located downstream of the semi-dry purifier 2, It is used to remove dust from the flue gas after desulfurization and denitrification. The chimney 4 is located downstream of the dust collector 3 and is used to discharge the purified flue gas.

[0043]The oxidation device 1 is located between the semi-dry purifier 2 and the flue gas source. After the nitric oxide in the flue gas is oxidized, it enters the semi-dry purifier 2 for desulfurization and denitration reactions.

[0044] The...

Embodiment 2

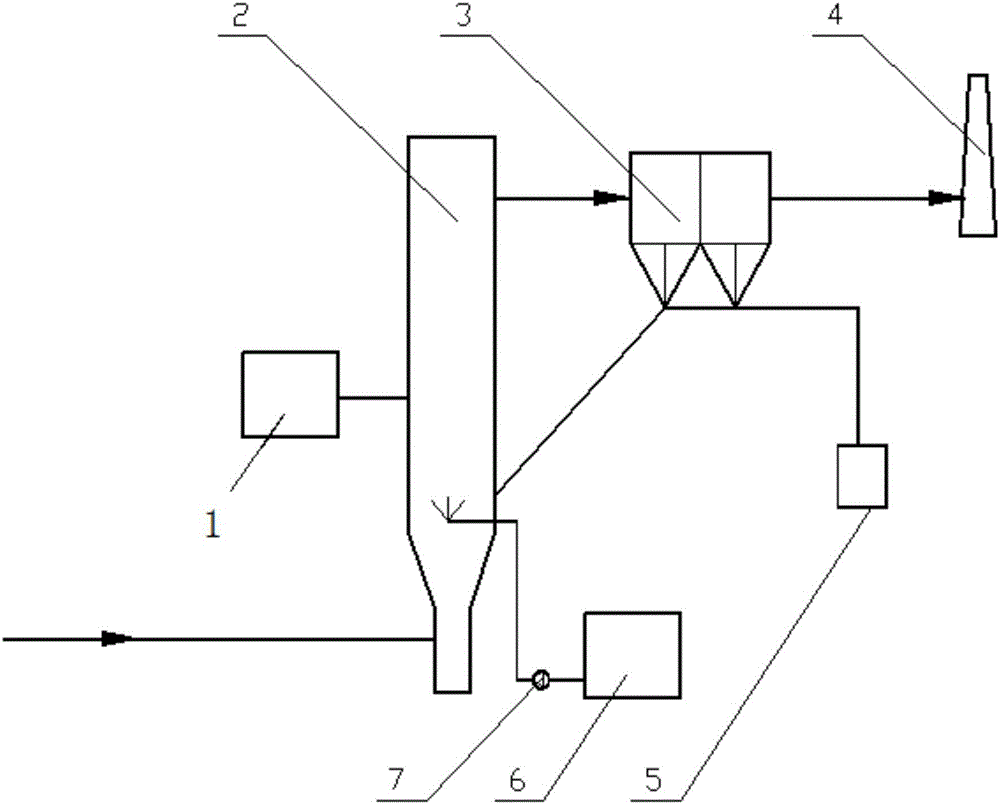

[0060] Such as figure 2 As shown, the semi-dry purifier 2 is directly connected to the flue gas source, the oxidation device 1 is connected to the interior of the semi-dry purifier 2, and the oxidation device 1 directly puts the oxidant into the semi-dry purifier 2 for oxidation reaction.

[0061] The oxidation device 1 may be an ozone generator.

[0062] A semi-dry desulfurization and denitrification method based on biomass ash, comprising the steps of:

[0063] The flue gas from the flue gas source first enters the semi-dry purifier 2, and ozone is passed into the semi-dry purifier 2 to adjust the temperature and humidity of the flue gas in the semi-dry purifier 2, and perform desulfurization and denitrification reactions The flue gas after desulfurization and denitrification flows out from the upper outlet of the semi-dry purifier 2, and is discharged after dust removal.

[0064] Adjust the temperature of the flue gas in the semi-dry purifier 2 to be 160° C., and the moi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap